Laser cladding alloy powder and laser cladding method for H13 die steel

A technology of laser cladding and alloy powder, which is applied in surface engineering applications and the field of surface engineering, can solve problems such as microscopic cracks in the cladding layer, and achieve the effects of improving wettability, good metallurgical bonding, high wear resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]H13 mold steel (size: 50mm×30mm×10mm) was selected as the substrate for pretreatment before cladding: degreasing, derusting and sanding until the surface roughness was Ra=0.2μm, and finally cleaned with acetone and alcohol.

[0039] With argon as the protective atmosphere, laser cladding is carried out by using LDM2000 multifunctional CNC laser cladding machine. Among them, the overlap coefficient is 0.6, the power P is 700W, the spot diameter D is 3mm, and the scanning speed V S 300mm / s, powder feeding speed V f It is 18g / s.

[0040] In this embodiment, 90% H13 + 10% nickel-coated WC alloy powder is used for laser cladding, and the particle size of the alloy powder is 150 μm; the substrate preheating temperature is 150° C.

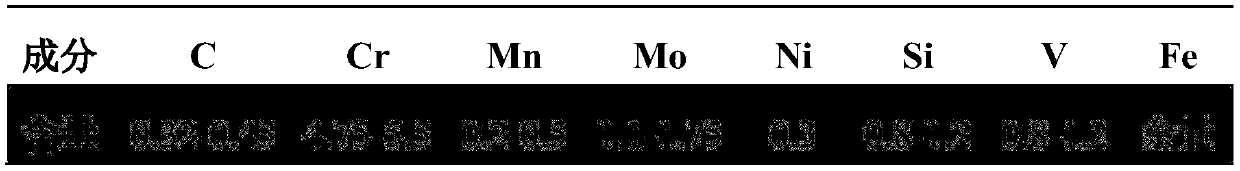

[0041] Table 1 Composition wt% of H13 alloy powder

[0042]

[0043]

[0044] The cladding layer of the cladding sample has a bright appearance, no cracks, and good formability. It forms a phase structure dominated by ferrite and supplement...

Embodiment 2

[0046] H13 mold steel (size: 50mm×30mm×10mm) was selected as the substrate for pretreatment before cladding: degreasing, derusting and sanding until the surface roughness was Ra=0.2μm, and finally cleaned with acetone and alcohol.

[0047] With argon as the protective atmosphere, laser cladding is carried out by using LDM2000 multifunctional CNC laser cladding machine. Among them, the power P is 900W, the spot diameter D is 3mm, and the scanning speed V S 350mm / s, powder feeding speed V f It is 20g / s.

[0048] In this embodiment, 70% H13 + 30% WC alloy powder is used for laser cladding, the particle size of the alloy powder is 180 μm, and the substrate preheating temperature is 200° C.

[0049] Among them, the composition of the H13 alloy powder is shown in Table 1.

[0050] Table 1 Composition wt% of H13 alloy powder

[0051]

[0052] The cladding layer of the cladding sample has a bright appearance, no cracks, and good formability. It forms a phase structure dominated...

Embodiment 3

[0054] H13 mold steel (size: 50mm×30mm×10mm) was selected as the substrate for pretreatment before cladding: degreasing, derusting and sanding until the surface roughness was Ra=0.2μm, and finally cleaned with acetone and alcohol.

[0055] With argon as the protective atmosphere, laser cladding is carried out by using LDM2000 multifunctional CNC laser cladding machine. Among them, the power P is 600W, the spot diameter D is 4mm, and the scanning speed V S 400mm / s, powder feeding speed V f It is 25g / s.

[0056] In this embodiment, 50% H13 + 50% WC alloy powder is used for laser cladding, the particle size of the alloy powder is 300 μm, and the substrate preheating temperature is 350° C.

[0057] Among them, the composition of the H13 alloy powder is shown in Table 1.

[0058] Table 1 Composition wt% of H13 alloy powder

[0059]

[0060] The cladding layer of the cladding sample has a bright appearance, no cracks, and good formability. It forms a phase structure dominated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com