Anti-ultraviolet paint for cosmetic packing bottles and preparation method and application technique thereof

An anti-ultraviolet, packaging bottle technology, applied in the field of coatings, can solve the problems of easy separation of cosmetic fat and water, cosmetic deterioration and failure, oxidation of oils and fragrances, etc., and achieves low water absorption, improved corrosion resistance, and good water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

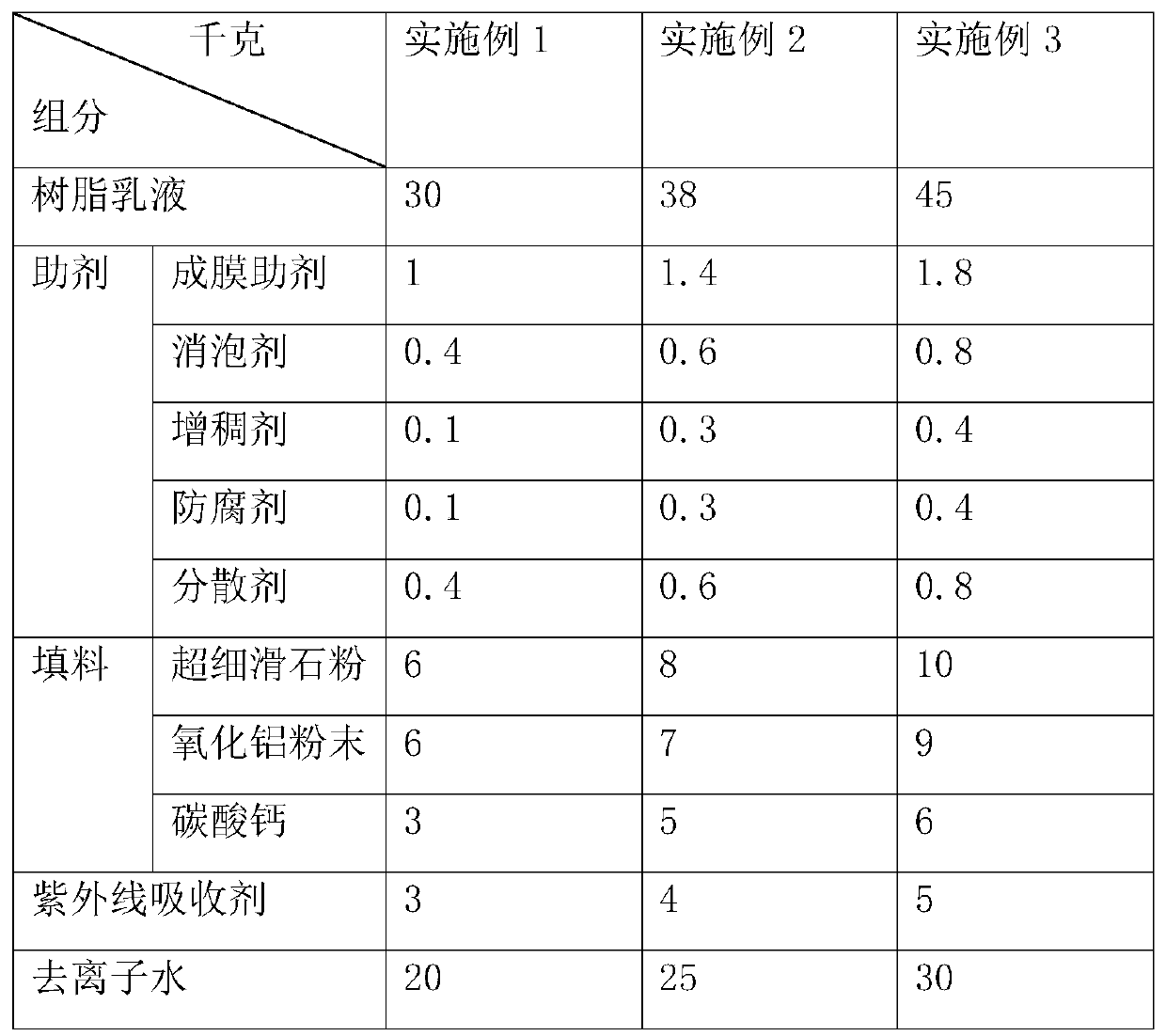

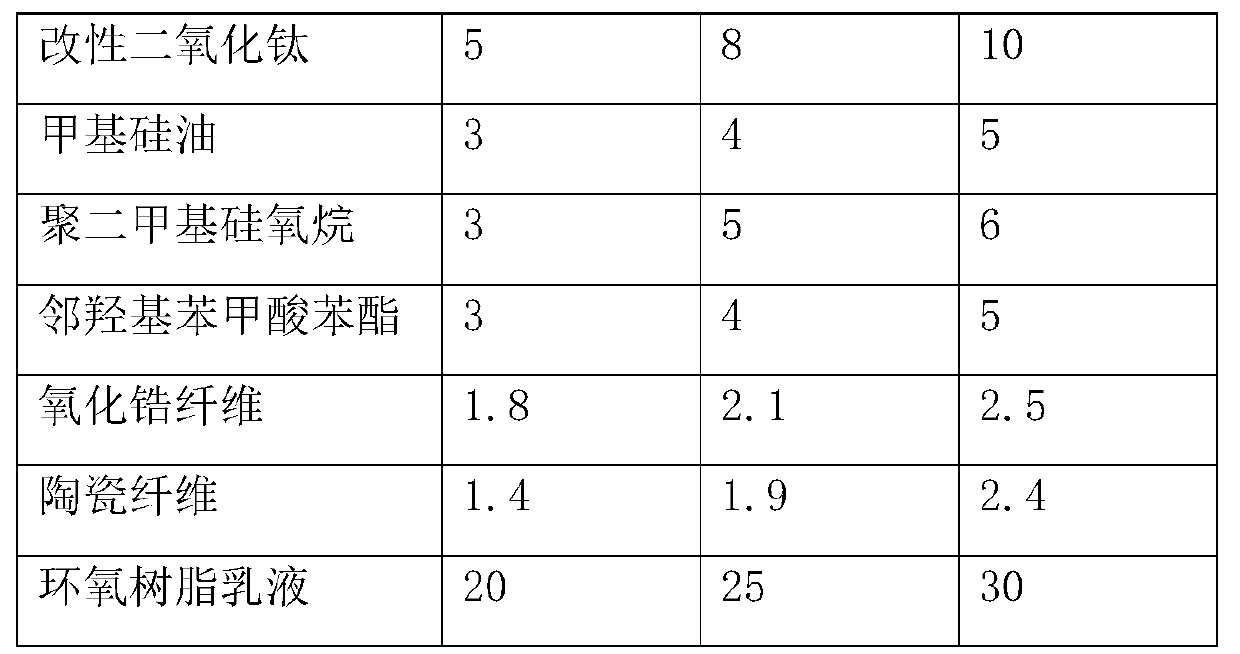

Examples

preparation example 1-3

[0042] The silane coupling agent KH570 is selected from the silane coupling agent of the model KH-570 sold by Guangzhou Baocheng New Material Technology Co., Ltd. The ceramic powder is selected from the product number 256-9 sold by Yancheng Mineral Products Processing Factory, Lingshou County, Shijiazhuang City The ceramic powder, titanium dioxide is selected from the titanium dioxide of the model NTR606 sold by Guangzhou Xueyu Trading Co., Ltd.

preparation example 1

[0043] Preparation example 1: (1) Add 1kg of silane coupling agent KH570 into deionized water, mix well, add 3kg of titanium dioxide and 3kg of ceramic powder, stir at 250r / min for 10min, centrifuge at 4000r / min for 30min, Wash twice with deionized water, and dry to constant weight at 78°C;

[0044] (2) Add 4 kg of styrene, 3 kg of polytetrafluoroethylene and 2 kg of polyvinyl alcohol to the product obtained in step (1), ultrasonically treat it for 10 minutes, add 1 kg of ammonium persulfate, react for 4 hours, suction filter, wash and vacuum dry.

preparation example 2

[0045] Preparation example 2: (1) Add 2kg of silane coupling agent KH570 into deionized water, mix well, add 6kg of titanium dioxide and 4kg of ceramic powder, stir at 280r / min for 15min, centrifuge at 4200r / min for 32min, Wash twice with deionized water and dry at 81°C until constant weight;

[0046] (2) Add 5 kg of styrene, 3.5 kg of polytetrafluoroethylene and 4 kg of polyvinyl alcohol to the product obtained in step (1), ultrasonically treat it for 13 minutes, add 2 kg of ammonium persulfate, react for 4.5 hours, suction filter, wash and vacuum dry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com