Phthalate hydrogenation catalyst, preparation method thereof and application of catalyst

A phthalate, hydrogenation catalyst technology, applied in the preparation of carboxylate, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of affecting catalyst utilization efficiency and selectivity , the low accessibility of phthalates, the high dispersion of catalyst active components, etc., to achieve the effects of high product yield, low loading, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

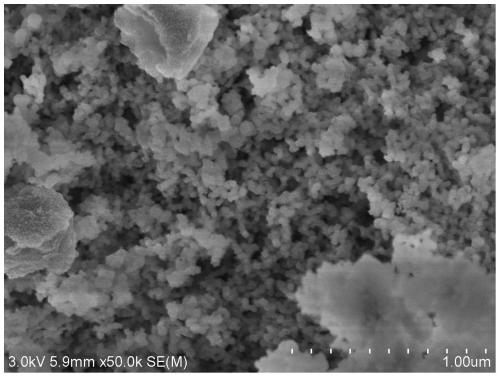

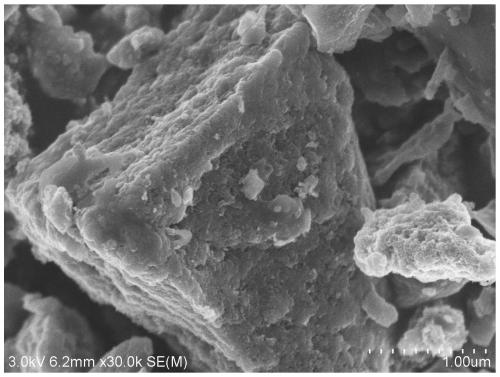

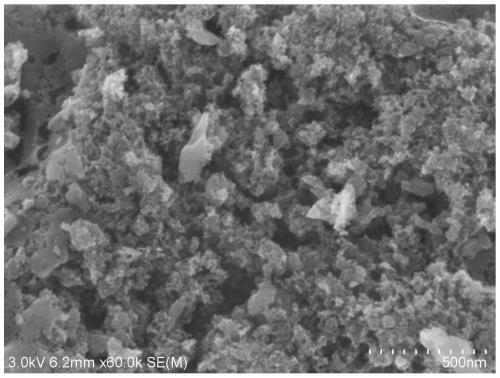

Image

Examples

preparation example Construction

[0035] The preparation method of above-mentioned phthalate hydrogenation catalyst comprises the following steps:

[0036] (1) Add the first carrier of 100-200 mesh and the second carrier of 200-400 mesh into the ball mill according to the metering, carry out ball milling for 5-10 hours, and mix well;

[0037] (2) Dry the mixed composite carrier at 110°C-120°C for 12-24 hours;

[0038] (3) Take an aqueous solution of alkaline earth metal nitrate compound to impregnate the composite carrier with equal volume, then dry at 100-140°C for 10-24 hours, and bake at 400-500°C for 2-6 hours under an inert atmosphere;

[0039] (4) Dissolving ruthenium trichloride in deionized water or alcohol is configured into an aqueous solution or an alcohol solution, and saturating and impregnating the composite carrier after the above-mentioned loading aid with the solution to form a catalytic matrix;

[0040] (5) Dry the catalyst precursor at 20°C-40°C for 12-24 hours, and then at 110°C-120°C for ...

Embodiment 1

[0047] Weigh 3g of fruit shell activated carbon, grind and sieve to get 100-200 mesh, weigh 2g200-400 mesh ZrO2, add activated carbon and ZrO2 to a planetary ball mill (Nanjing Chishun Technology Development Co., Ltd., XQM-2L), and turn at 200 rpm Perform ball milling and mixing within a range of 10 hours per minute; the mixed composite carrier is dried at 120° C. for 12 hours. Take 0.1037 g of anhydrous ruthenium trichloride and dissolve it in deionized water, add it to the dried composite carrier, stir evenly, dry at room temperature for 12 hours, and dry at 120° C. for 12 hours. Then, the catalyst precursor impregnated with active components was calcined at 300° C. for 4 h in a nitrogen atmosphere. Catalyst A was obtained after reduction at 200° C. for 3 h in a hydrogen atmosphere (0.05-0.15 MPa), wherein the active component accounted for 1% of the total mass of the carrier.

[0048] Using 2.5g of di-isooctyl phthalate as raw material and 25g of ethanol as solvent, weigh ...

Embodiment 2

[0050] Weigh 6g of coconut shell activated carbon, grind and sieve to take 100-200 mesh, weigh 4g of 200-400 mesh SiO2, add activated carbon and SiO2 to a ball mill, and perform ball milling and mixing for 10 hours; the mixed composite carrier is extruded into strips, ground Sieve 20-40 mesh and dry at 140°C for 12h. 0.2074 g of anhydrous ruthenium trichloride was dissolved in deionized water, added to the dried carrier, stirred evenly, dried at room temperature for 12 hours, and dried at 140°C for 12 hours. Calcined at 400°C for 4h in a nitrogen (0.1-0.15MPa) atmosphere. Catalyst B was obtained after reduction at 200° C. for 4 h in a hydrogen atmosphere (0.05-0.15 MPa), wherein the active component accounted for 1% of the total mass of the carrier.

[0051] Using 2.5g of di-isooctyl phthalate as raw material and 25g of ethanol as solvent, weigh 0.5g of catalyst B, and react for 4 hours at a reaction temperature of 120°C, an initial hydrogen pressure of 5.0MPa, and a stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com