Self-repaired waterborne polyurethane material and preparation method thereof

A water-based polyurethane, self-healing technology, applied in the field of materials, to achieve the effects of good self-healing performance, simple operation and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

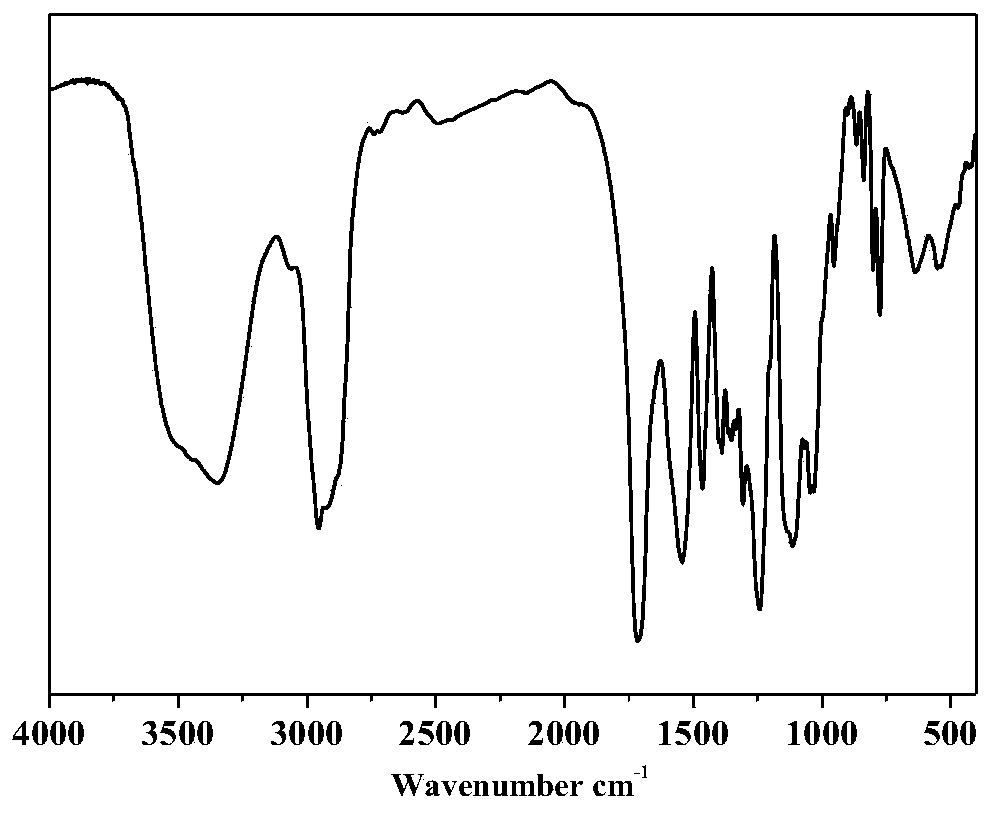

[0032] The invention provides a kind of preparation method of self-repairing waterborne polyurethane, comprising:

[0033] A) heating and dehydrating the macromolecular diol and reacting with diisocyanate under stirring to obtain the first prepolymer;

[0034] B) reacting the first prepolymer with an organic solvent, a small molecule diol chain extender containing a furan ring, a hydrophilic chain extender, an end-capping agent and a catalyst to obtain a second prepolymer;

[0035] C) neutralizing the second prepolymer with a neutralizing agent, then reacting with a diamine chain extender in deionized water, after high-speed dispersion and emulsification, removing the solvent in a vacuum to obtain an aqueous polyurethane emulsion;

[0036] D) mixing the water-based polyurethane emulsion with the maleimide cross-linking agent, and heating and reacting to obtain the self-healing water-based polyurethane.

[0037] The preparation method of the self-healing water-based polyuretha...

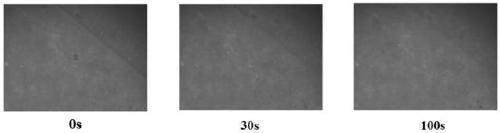

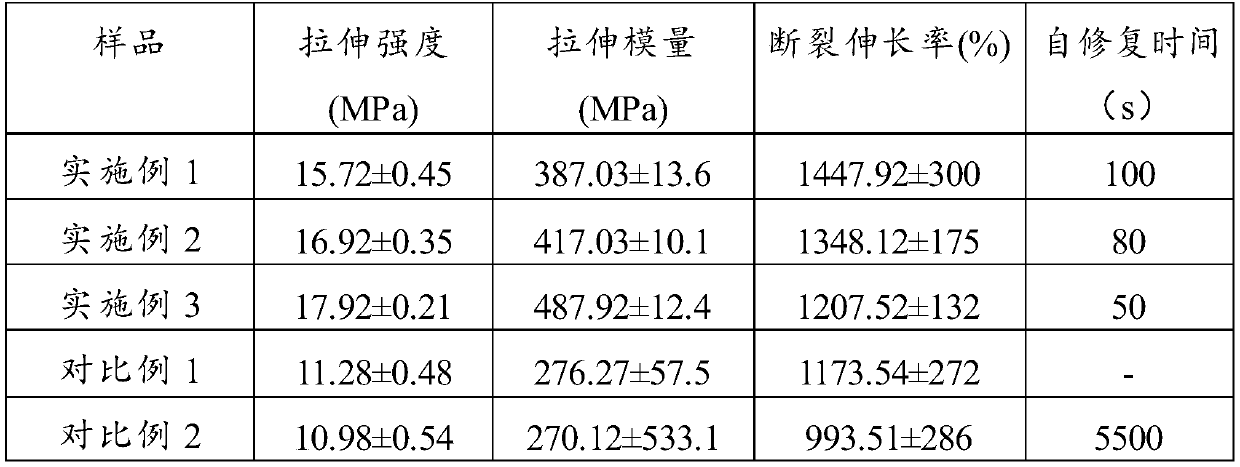

Embodiment 1

[0066] (1) Add 40.00g of polyethylene glycol 4000 into the reactor, heat to 100°C, use an oil pump to remove water for 4h, cool down to 70°C, add 15.01g of isophorone diisocyanate into the reactor, stir, React for 40 minutes under the protection of nitrogen, lower the temperature to 50°C, dissolve 1.84g of 2,5-furandimethanol, 3.06g of dimethylolbutyric acid and 0.015g of dibutyltin laurate in 60g of acetone and add it dropwise to the reactor. After the solution was completed, the reaction was continued for 6 hours, the temperature was lowered to 40° C., and 2.511 g of triethylamine was added for neutralization for 2 hours.

[0067] Dissolve 1.35g of ethylenediamine in 300ml of deionized water. After the reaction system is cooled to room temperature, slowly drop it into the deionized water in which ethylenediamine is dissolved, and at the same time stir and disperse at a high speed (stirring speed 8000rpm). Continue to Stir for 1 h, filter with gauze, and then use a rotary eva...

Embodiment 2

[0070] (1) Add 40.00g of polyethylene glycol 4000 into the reactor, heat to 100°C, use an oil pump to remove water for 4h, cool down to 70°C, add 15.01g of isophorone diisocyanate into the reactor, stir, Under the protection of nitrogen, react for 40min, lower the temperature to 50°C, dissolve 2.24g of 2,5-furandimethanol, 2.59g of dimethylolbutyric acid and 0.015g of dibutyltin laurate in 60g of acetone and add it dropwise to the reactor. After the solution was completed, the reaction was continued for 7 hours, the temperature was lowered to 35° C., and 1.77 g of triethylamine was added for neutralization for 1 hour.

[0071] Dissolve 0.66g of ethylenediamine in 300ml of deionized water. After the system is cooled to room temperature, slowly drop it into the deionized water in which ethylenediamine is dissolved, and at the same time stir and disperse at a high speed (stirring speed 8000rpm). Continue to Stir for 1 h, filter with gauze, and then use a rotary evaporator to remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com