Silicone rubber rhinoplasty prosthesis and manufacturing method thereof

A technology of silicone and rhinoplasty, which is applied in prosthesis, nose implants, medical science, etc., can solve the problems of unstable engraving effect of prosthesis, prone to dislocation, and unstable matching degree, so as to reduce the exposure of prosthesis Probability, operation time saving, and effect of reducing material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1. Obtain patient nasal image data through CT, MRI, 3D photography and other medical imaging equipment;

[0045] 2. Import the acquired image data into the special medical 3D modeling software to establish the 3D data model of the patient's nose;

[0046] 3. Design the surgical plan based on the obtained 3D data model of the patient's nose, and design the silicone nasal prosthesis;

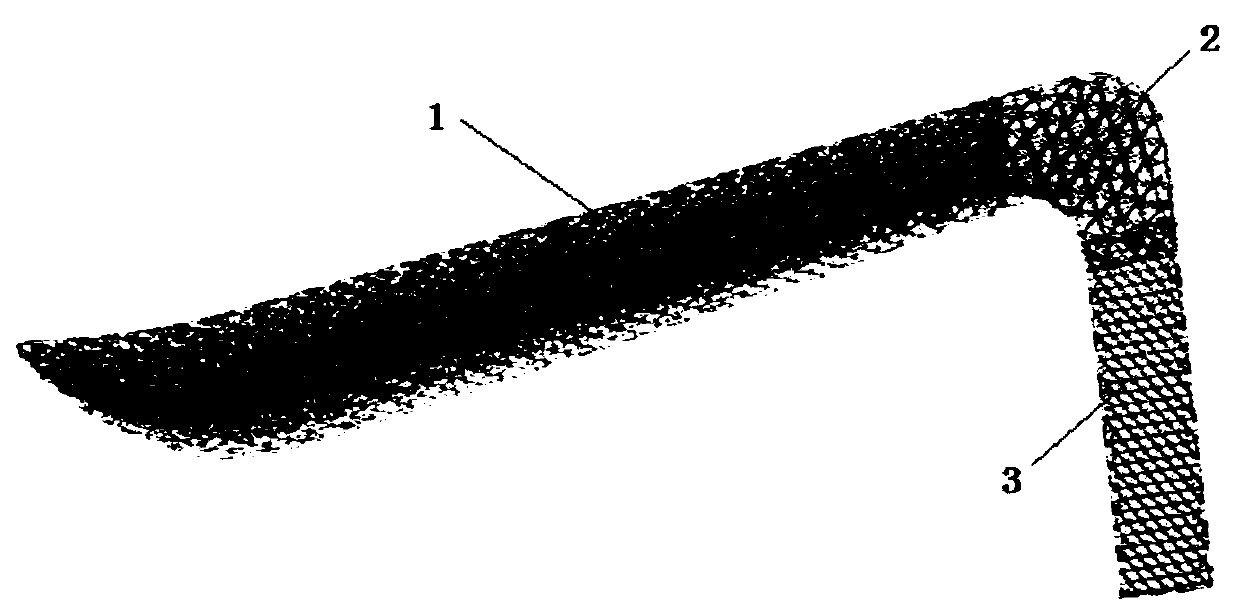

[0047] 4. For the overall design of the silicone nasal prosthesis, the segmented structure design is carried out. According to the hardness of different parts of the human nose bridge, the porosity of the outer layer of the back of the nose part 1 is designed to be 80%, and the porosity of the inner part of the back of the nose is 20%. The porosity of the nose tip part 2 is 80%, and the columella part 3 is 30% of the porosity; the back part of the nose has an inner and outer double-layer structure, the thickness of the outer layer is 2mm, and the thickness of the inner layer is 5mm;

[004...

Embodiment 2

[0056] 1. Obtain patient nasal image data through CT, MRI, 3D photography and other medical imaging equipment;

[0057] 2. Import the acquired image data into the special medical 3D modeling software to establish the 3D data model of the patient's nose;

[0058] 3. Design the surgical plan based on the obtained 3D data model of the patient's nose, and design the silicone nasal prosthesis;

[0059] 4. For the designed silicone nasal prosthesis, the segmented structure design is carried out. According to the hardness of different parts of the human nose bridge, the porosity of the nasal dorsal part 1 is designed to be 30%, the porosity of the nasal tip part 2 is 60%, and the nasal columella Part 3 has a porosity of 50%;

[0060] 5. If Figure 7 As shown, the intersecting line unit of the mesh structure of the silicone rhinoplasty prosthesis is designed to be in the shape of a "meter" formed by four intersecting lines. mm;

Embodiment 3

[0068] 1. Obtain patient nasal image data through CT, MRI, 3D photography and other medical imaging equipment;

[0069] 2. Import the acquired image data into the special medical 3D modeling software to establish the 3D data model of the patient's nose;

[0070] 3. Design the surgical plan based on the obtained 3D data model of the patient's nose, and design the silicone nasal prosthesis;

[0071] 4. Design the segmented structure of the silicone nasal prosthesis as a whole. According to the hardness of different parts of the human nose bridge, design the porosity of the outer layer of the back of the nose part 1 to be 40%, and the porosity of the inner part of the back of the nose to be 10%. The porosity of nose tip part 2 is 40%, and the porosity of nose columella part 3 is 40%; the back part of the nose has an inner and outer double-layer structure, the thickness of the outer layer is 3mm, and the thickness of the inner layer is 4mm;

[0072] 5 as Figure 5 and Figure 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com