Substrate having functional coating and temporary protection layer

A functional and protective layer technology, applied in the field of protection of glass substrates, can solve the problems of washing machine pollution, cold corrosion, unprotected functional coatings, etc., and achieve the effect of simplifying industrial implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

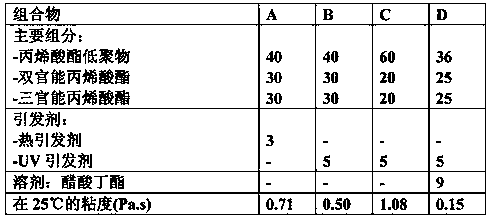

[0160] I. Materials used

[0161] 1. Substrate and functional layer

[0162] The substrate used was a flat glass substrate with a thickness of about 6 mm obtained by the flotation method consisting in pouring molten glass onto a tin bath.

[0163] Functional coatings providing solar control properties and comprising stacks of thin layers were deposited using a magnetron cathode sputtering device.

[0164] The first functional coating, hereinafter referred to as triple Ag-layer, comprises an alternation of three silver layers (metallic functional layers) and four anti-reflective coatings in succession starting from the substrate, each anti-reflective coating comprising at least one A dielectric layer such that each metallic functional layer is disposed between two antireflection coatings. The total thickness of this functional coating is 200-250 nm.

[0165] The second functional coating (hereinafter referred to as double Ag layer) consists of a stack of thin layers comprisi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com