Hemp Fiber Reinforced Polypropylene Composites Favorable for Separation and Recycling and Its Preparation

A composite material and hemp fiber technology, applied in the field of hemp fiber reinforced polypropylene composite materials, can solve the problems of increasing the difficulty of separating and recycling resin, unfavorable environmental protection, etc., and achieve excellent chemical adsorption, low environmental burden, and high structural design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

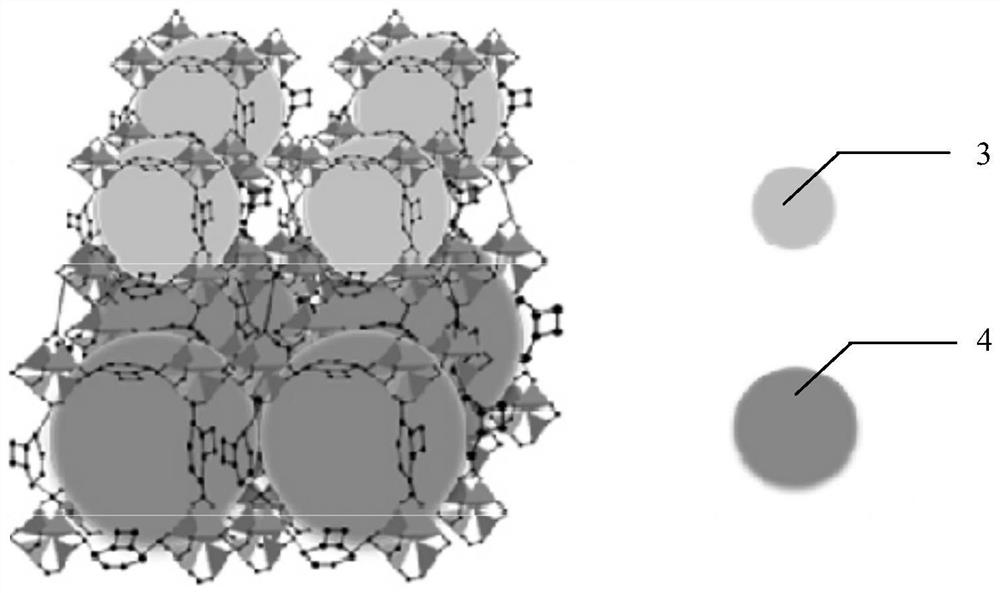

[0048] Such as figure 1 As shown, this embodiment provides a hemp fiber reinforced polypropylene composite material that is beneficial to separation and recovery, including three layers of polypropylene layers arranged in sequence from top to bottom, and a layer of hemp fiber is arranged between adjacent two layers of polypropylene layers. In the fiber layer, a self-assembled degradable material is arranged between the polypropylene layer and the hemp fiber layer. The degradable self-assembly material is MOFs, and the hemp fiber layer is hemp fiber nonwoven fabric.

[0049] Such as figure 2 As shown, the degradable self-assembled material has a good morphological structure and a special grain packing method, which can act as a bond to "bundle" the fiber base and the resin base together to achieve molecular-level coating and endow the composite material Compact structure and good mechanical properties.

[0050] The preparation steps of the hemp fiber reinforced polypropylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com