Production method of three-dimensional porous composite bar

A three-dimensional porous, composite rod technology, applied in medical science, prosthesis, etc., can solve the problems of uneven dispersion of pores and poor mechanical properties, and achieve good biocompatibility, low cost, thermal stability and improved mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

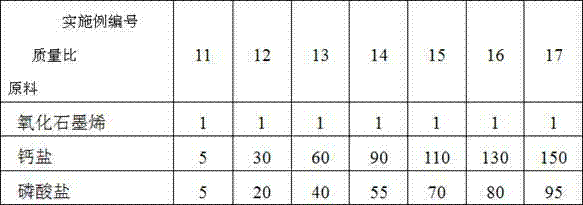

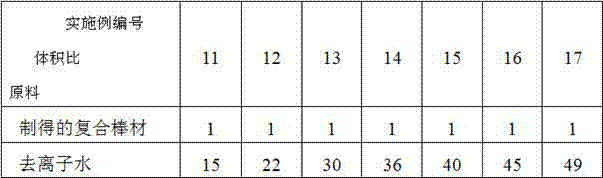

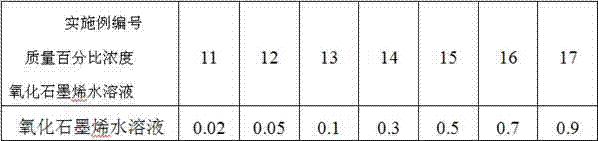

Embodiment 1

[0024] The graphene oxide powder was added to 250 mL of deionized water solution, and ultrasonically stirred for 1 hour to obtain a graphene oxide solution with a concentration of 1 mg / mL. Calcium nitrate and potassium dihydrogen phosphate are added to the graphene oxide solution according to the calcium ion concentration of 0.4kg / L and the phosphorus ion concentration of 0.18kg / L, and stirred evenly to obtain a graphene oxide hydroxyapatite precursor solution, while 7.5 g of konjac glucomannan was added while stirring to obtain a mixed solution, which was stirred at a constant temperature of 45° C. for 30 minutes, and stood for deaeration for 24 hours. The above solution was injected into a dialysis bag, sealed with a dialysis bag clip, and penetrated into an alkaline coagulation solution with a mass concentration of 1.5%, soaked at a constant temperature of 60 ° C for 7 days to obtain graphene oxide modified konjac glucomannan / hydroxyapatite Stone three-dimensional porous co...

Embodiment 2

[0027] The graphene oxide powder was added to 250 mL of deionized aqueous solution, and ultrasonically stirred for 0.5 hours to obtain a graphene oxide solution with a concentration of 1 mg / mL. Calcium nitrate and potassium dihydrogen phosphate are added to the graphene oxide solution according to the calcium ion concentration of 1.6kg / L and the phosphorus ion concentration of 0.72kg / L, and stirred evenly to obtain the graphene oxide hydroxyapatite precursor solution. 7.5 g of konjac glucomannan was added while stirring to obtain a mixed solution, which was stirred at a constant temperature of 45° C. for 30 minutes, and stood for deaeration for 24 hours. The above solution was injected into a dialysis bag, sealed with a dialysis bag clip, and penetrated into an alkaline coagulation solution with a mass concentration of 1.5%, soaked at a constant temperature of 60 ° C for 7 days to obtain graphene oxide modified konjac glucomannan / hydroxyapatite Stone three-dimensional porous c...

Embodiment 3

[0030] The graphene oxide powder was added to 250 mL of deionized aqueous solution, and ultrasonically stirred for 0.6 hours to obtain a graphene oxide solution with a concentration of 5 mg / mL. Calcium nitrate and potassium dihydrogen phosphate are added to the graphene oxide solution according to the calcium ion concentration of 1.6kg / L and the phosphorus ion concentration of 0.72kg / L, and stirred evenly to obtain the graphene oxide hydroxyapatite precursor solution. 10 g of konjac glucomannan was added while stirring to obtain a mixed solution, which was stirred at a constant temperature of 45° C. for 30 minutes, and then left to stand for deaeration for 24 hours. The above solution was injected into a dialysis bag, sealed with a dialysis bag clip, and penetrated into an alkaline coagulation solution with a mass concentration of 1.5%, soaked at a constant temperature of 60 ° C for 7 days to obtain graphene oxide modified konjac glucomannan / hydroxyapatite Stone three-dimensio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com