Ultrahigh-toughness combined bridge deck formed by assembling and connecting angle steel and profiled steel sheets

A profiled steel plate, ultra-high toughness technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of difficult to guarantee construction quality and accuracy, increase construction workload, increase construction volume, etc., to avoid difficult to guarantee construction accuracy. , The effect of blocking the steel and the external environment and reducing the complexity of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

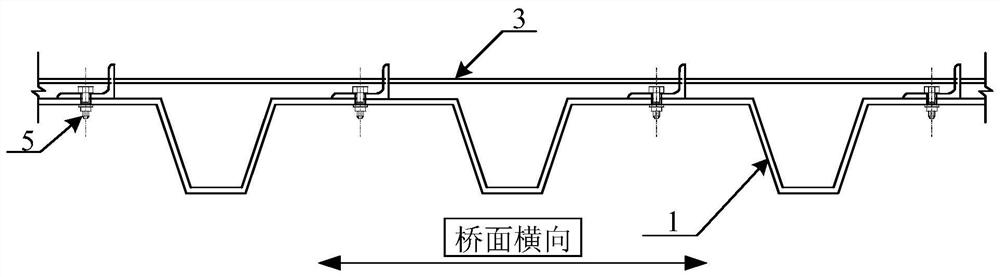

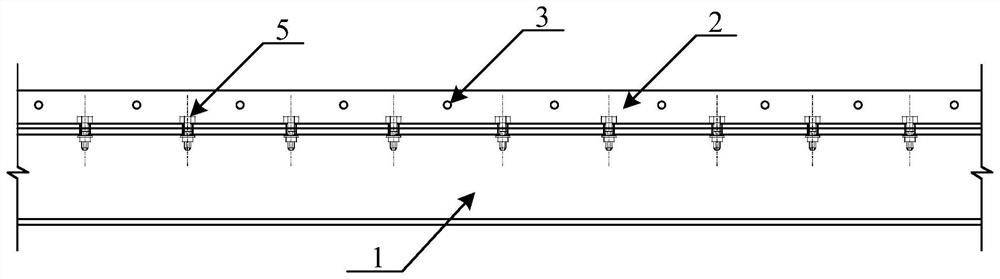

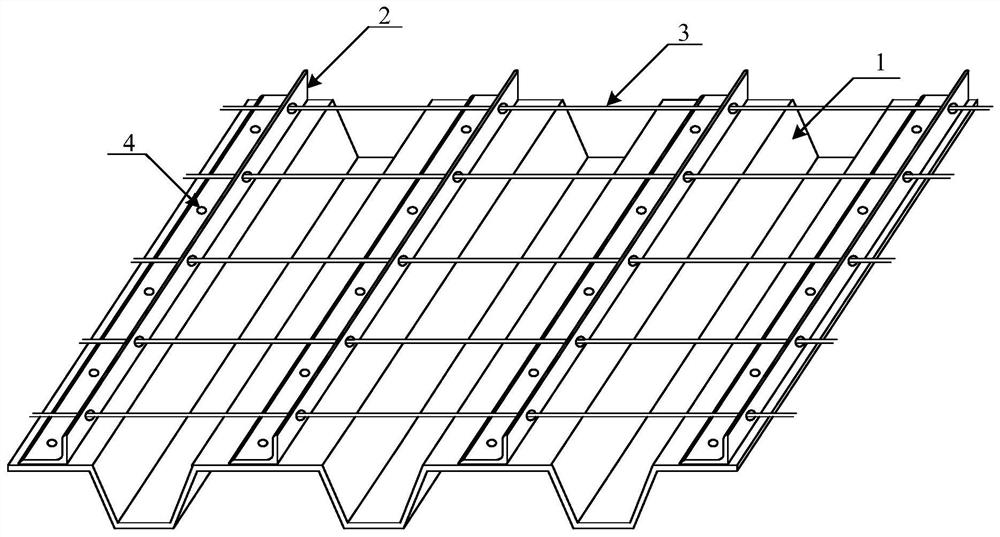

[0041] like Figure 1 ~ Figure 3 As shown, the bridge deck steel skeleton includes the following components: profiled steel plate 1, angle steel 2, round steel rod 3, bolt hole 4, high-strength bolt 5, and ultra-high toughness concrete 6. The construction method is to set bolt holes 4 at equal intervals on the upper flange (ie, the top surface) of the profiled steel plate 1 and the long leg of the angle steel 2 (the side with a larger width), and set bolt holes 4 at equal intervals on the short leg of the angle steel 2 (the side with a smaller width). Spacing is opened the circular hole that diameter is slightly larger than round steel rod 3, high-strength bolt 5 is passed through bolt hole 4 to connect profiled steel plate 1 and angle steel 2, and round steel rod 3 is passed through circular hole.

[0042] like Figure 4 ~ Figure 5 As shown, the ultra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com