Anti-aging rubber material for rubber-lined pipeline of nuclear power station and preparation method of anti-aging rubber material

A rubber material and aging-resistant technology, which is applied in the field of aging-resistant rubber materials and preparations for rubber-lined pipelines in nuclear power plants, and can solve the problems of short service life of aging-resistant rubber materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The second aspect of the embodiment of the present application provides a method for preparing an aging-resistant rubber material for a rubber-lined pipeline in a nuclear power plant, comprising the following steps:

[0034] Step S10: weighing each raw material component according to the components contained in the aging-resistant rubber material for the rubber-lined pipeline of the nuclear power plant;

[0035] Step S20: performing mixing treatment, rubber mixing treatment and vulcanization treatment on each raw material component to obtain an aging-resistant rubber material for a rubber-lined pipeline of a nuclear power plant.

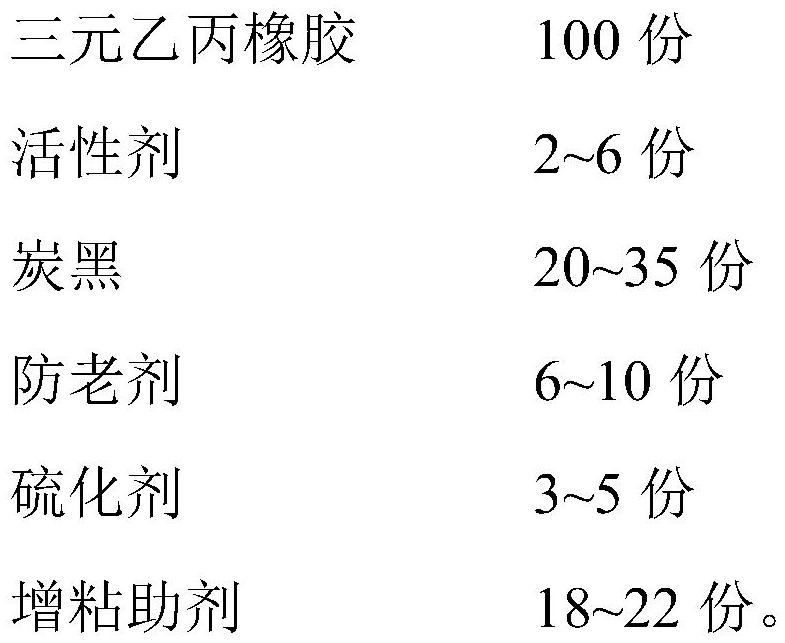

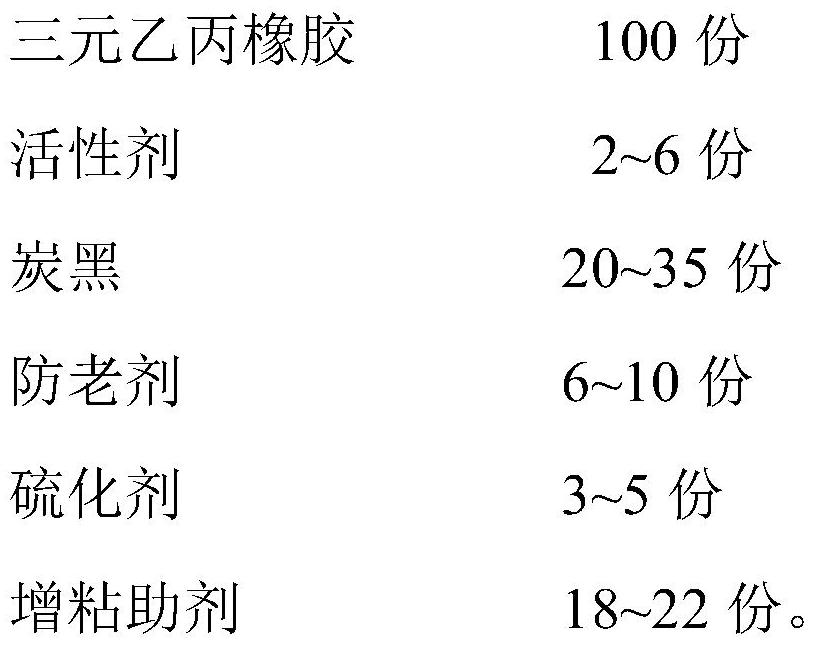

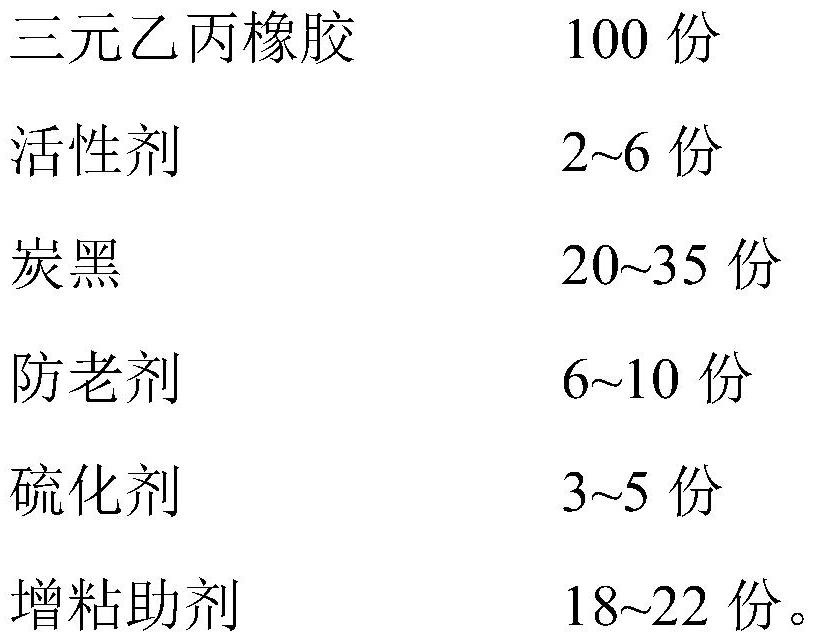

[0036] The embodiment of the present application weighs each raw material component according to the components contained in the aging-resistant rubber material for the above-mentioned nuclear power plant rubber-lined pipeline and mixes them, so that EPDM rubber, active agent, carbon black, anti-aging agent, vulcanizing agent, The viscosity-in...

Embodiment 1

[0055] The aging-resistant rubber material for nuclear power plant rubber-lined pipelines of this embodiment, raw materials and weight are: 100 parts of EPDM rubber, 3.5 parts of activator, 25 parts of carbon black, 6.7 parts of anti-aging agent, 3.6 parts of vulcanizing agent, viscosity increasing 20 doses.

[0056] The EPDM rubber is ENB type ethylene propylene rubber, the ethylene content is 68.5%, the propylene content is 22.2%, and the ethylidene norbornene (ENB) content is 9.3%;

[0057] The active agent is zinc oxide;

[0058] Carbon black is 15 parts of N550 and 10 parts of gas carbon black;

[0059] The anti-aging agent is N-(1,3-dimethyl)butyl-N'-phenyl-p-phenylenediamine (anti-4020) 3 parts, 2-mercaptobenzimidazole (anti-MB) 2 parts, N-phenyl - 1.5 parts of 2-naphthylamine (anti-D), 0.2 parts of N-cyclohexylthiophthalimide (anti-scorch CTP);

[0060] The vulcanizing agent is 2,5-dimethyl-2,5-bis-tert-butylperoxyhexane (bis-25) 3 parts, cyanuric acid triallylonitr...

Embodiment 2

[0071] The aging-resistant rubber material for the rubber-lined pipeline of the nuclear power plant of the present embodiment, raw materials and weight are: 100 parts of EPDM rubber, 3.5 parts of activator, 25 parts of carbon black, 6.7 parts of anti-aging agent, 3.6 parts of vulcanizing agent, viscosity increasing 20 doses.

[0072] The EPDM rubber is ENB type ethylene propylene rubber, the ethylene content is 68.5%, the propylene content is 22.2%, and the ethylidene norbornene (ENB) content is 9.3%;

[0073] The active agent is zinc oxide;

[0074] Carbon black is 15 parts of N550 and 10 parts of gas carbon black;

[0075] The anti-aging agent is N-(1,3-dimethyl)butyl-N'-phenyl-p-phenylenediamine (anti-4020) 3 parts, 2-mercaptobenzimidazole (anti-MB) 2 parts, N-phenyl - 1.5 parts of 2-naphthylamine (anti-D), 0.2 parts of N-cyclohexylthiophthalimide (anti-scorch CTP);

[0076] The vulcanizing agent is 2,5-dimethyl-2,5-bis-tert-butylperoxyhexane (bis-25) 3 parts, cyanuric a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| adhesion strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com