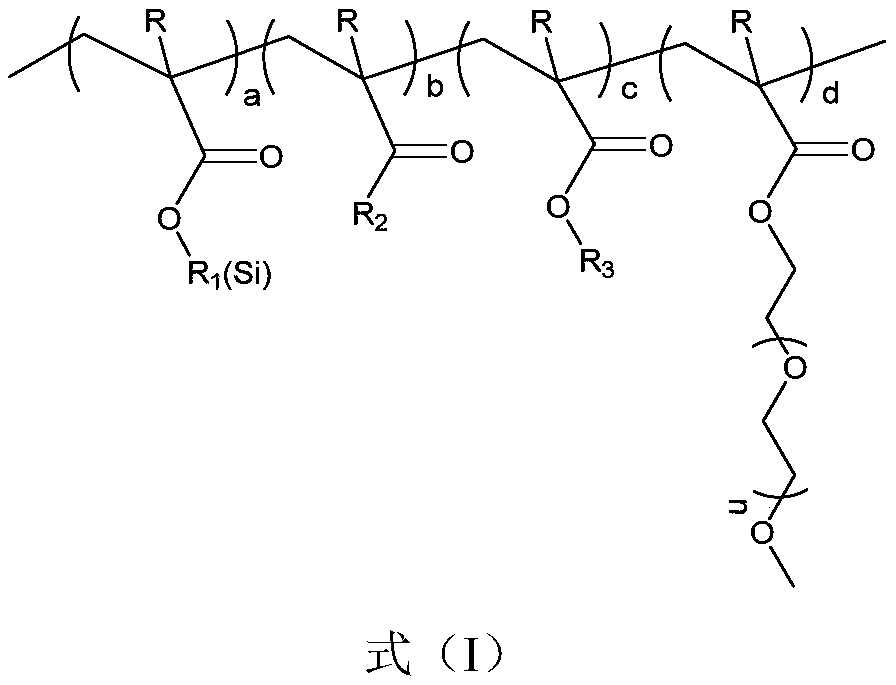

Silicon-containing polymer binder, preparation method and application in silicon-based electrode lithium ion battery thereof

A silicon polymer and binder technology, used in secondary batteries, battery electrodes, circuits, etc., can solve problems such as lack of practical application ability, achieve good electrochemical performance, improve conductivity, and good compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 Preparation of silicon-based electrode lithium ion battery binder and electrode coating.

[0025] Add solvent to a 50ml three-necked flask: 25g of butyl acetate, then add 2.7g of triisopropylsilyl acrylate, 0.5g of acrylic acid, 0.5g of butyl acrylate, and 1.1g of polyethylene glycol methacrylate. The stirrer was stirred, and NaOH was added dropwise to adjust the pH to 7, and then the temperature was raised to 80° C., and 0.01 g of azobisisobutyronitrile was added dropwise at one time. The product was obtained after reacting for 8 hours, and then the product was precipitated twice in n-hexane to obtain a viscous polymer which was then dissolved in 10 g of butyl acetate.

[0026] Add silicon powder: super P: binder = 7:2:1 mass ratio into the mortar and blend for 30 minutes, use the preparation device to coat the resulting slurry on the copper foil, put the copper foil in Dry in an oven at 60°C for 12 hours, then dry in an oven at 120°C for 12 hours, and then ...

Embodiment 2

[0027] Example 2 Preparation of silicon-based electrode lithium ion battery binder.

[0028] Add solvent to a 50ml three-necked flask: 25.3g of dioxane, then add 1.86g of γ-(methacryloyloxy)propyltrimethoxysilane, 0.5g of acrylic acid, 0.5g of methyl methacrylate, polyethylene glycol 2.7 g of diol methacrylate was stirred with a magnetic stirrer to adjust the pH to 7, then the temperature was raised to 75° C., and 0.055 g of dibenzoyl peroxide was slowly added dropwise. The product was obtained after reacting for 8 hours, and the product was precipitated twice in n-hexane after preliminary rotary evaporation and drying to obtain a viscous polymer, which was then dissolved in 10 g of dioxane

[0029] Add the mass ratio of silicon powder: super P: binder = 6:2:2 into the mortar and blend for 25 minutes, use the preparation device to coat the obtained slurry on the copper foil, put the copper foil in Dry in an oven at 120°C for 24 hours, and then slice into battery electrodes. ...

Embodiment 3

[0030] Example 3 Preparation of silicon-based electrode lithium ion battery binder.

[0031] Add solvents to a 50ml three-necked flask: dimethyl sulfoxide 5g, dioxane 15g, then add γ-(methacryloyloxy)propyltrimethoxysilane 3g, acrylic acid 1g, butyl acrylate 0.7g, 0.3 g of diethylene glycol dimethacrylate was stirred with a magnetic stirrer to adjust the pH to 7, then the temperature was raised to 70°C, 0.05 g of dibenzoyl peroxide was slowly added dropwise, and the product was obtained after continuing the reaction for 24 hours. It was then precipitated twice in n-hexane to obtain a viscous polymer, which was then dissolved in 10 g of dimethyl sulfoxide.

[0032] Add silicon powder: graphite: acetylene black: binder = 15:45:20:20 by mass ratio into the mortar, grind and blend for 30 minutes, and use the preparer to coat the resulting slurry on the copper foil. The copper foil was dried in an oven at 120°C for 12 hours, and then sliced into battery electrodes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com