High-stability halogen-free environmental-friendly fire retardant used for plastic, and preparation method thereof

A high stability, flame retardant technology, applied in the field of flame retardant, can solve the problems of limited application fields, increase of plastic specific gravity, poor processing performance, etc., to achieve the surface temperature of oxygen-isolated materials, reduce the surface temperature of materials, and improve compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

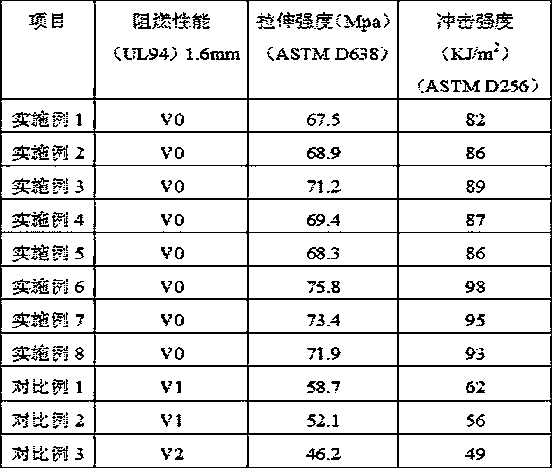

Examples

Embodiment 1

[0032] The high-stability halogen-free environmentally friendly flame retardant for plastics in this example is prepared from raw materials including the following components and parts by weight: 52 parts of modified polyorganosiloxane, 21 parts of fumed silica, modified silicon 10 parts of algae earth, 3 parts of surface treatment agent and 1 part of polyethylene wax.

[0033] Wherein, the preparation method of modified polyorganosiloxane comprises the following steps:

[0034] Step (I): Mix succinic resin and polyester resin uniformly in a mass ratio of 9:1, transfer to a mixer, heat to 130°C, stir at 2000r / min for 40min, then add The peroxide of 1.6% of polyester resin quality, stirs 60min with 4000r / min rotating speed again, naturally cools to room temperature, makes the blend of amber resin and polyester resin;

[0035] Step (II): Dissolve the blend of succinic resin and polyester resin in an organic solvent, then heat to 132°C, then add the catalyst, then add polyorgano...

Embodiment 2

[0049] The high-stability halogen-free environmentally friendly flame retardant for plastics in this example is prepared from raw materials including the following components and parts by weight: 58 parts of modified polyorganosiloxane, 22 parts of fumed silica, modified silicon 9 parts of algae earth, 2 parts of surface treatment agent and 1 part of polyethylene wax.

[0050] Wherein, the preparation method of modified polyorganosiloxane comprises the following steps:

[0051] Step (I): Evenly mix succinic resin and polyester resin together in a mass ratio of 8:1, transfer to a mixer, heat to 135°C, first stir at 1800r / min for 45min, then add The 1.7% peroxide of polyester resin quality, stirs 65min with 4200r / min rotating speed again, naturally cools to room temperature, makes the blend of amber resin and polyester resin;

[0052] Step (II): Dissolve the blend of succinic resin and polyester resin in an organic solvent, then heat to 134°C, then add the catalyst, then add po...

Embodiment 3

[0066] The high-stability halogen-free environmentally friendly flame retardant for plastics in this example is prepared from raw materials including the following components and parts by weight: 64 parts of modified polyorganosiloxane, 25 parts of fumed silica, modified silicon 12 parts of algae earth, 4 parts of surface treatment agent and 1.5 parts of polyethylene wax.

[0067] Wherein, the preparation method of modified polyorganosiloxane comprises the following steps:

[0068] Step (I): Evenly mix succinic resin and polyester resin together in a mass ratio of 10:1, transfer to a mixer, heat to 130°C, stir at 1500r / min for 40min, then add The peroxide of 1.8% of polyester resin quality, stirs 65min with 4500r / min rotating speed again, naturally cools to room temperature, makes the blend of amber resin and polyester resin;

[0069] Step (II): Dissolve the blend of succinic resin and polyester resin in an organic solvent, then heat to 135°C, then add the catalyst, then add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com