Cobalt iron alloy target material, magnetic conductive layer, magnetic capacitance unit, a magnetic capacitance device and fabrication method of magnetic capacitance device

A cobalt-iron alloy and magnetic capacitor technology, applied in the field of capacitors, can solve problems such as difficult problems, and achieve the effects of increased life, high startup efficiency and reliability, and high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A cobalt-iron alloy target used for magnetron sputtering coating, which is an alloy made of cobalt and iron with an atomic ratio of 6.5-8.5: 3.5-1.5.

[0043] The cobalt-iron alloy target can be prepared by the following steps: converting pure Co and Fe raw materials into a corresponding mass ratio CoFe=70.47-29.53 at an atomic ratio of 7:3. After removing the raw material impurities, it is smelted in a vacuum smelting furnace. The ratio of cobalt to iron atoms is controlled by a series of quality control such as spectrum testing: 6.5~8.5: 3.5~1.5 and the purity is not less than 95% (total cobalt and iron content ≥95% ), after determining the performance of the corresponding product, it will be processed by FANUC CNC machining center.

Embodiment 2

[0045] A magnetic conductive layer, which is composed of multiple layers of nano-scale magnetic films, wherein each layer of the nano-scale magnetic film is deposited by magnetron sputtering coating using the cobalt-iron alloy target of Example 1. The thickness of each layer of nano-scale magnetic film It is 5~25nm. Preferably, the total thickness is controlled to be 150-250 nm.

Embodiment 3

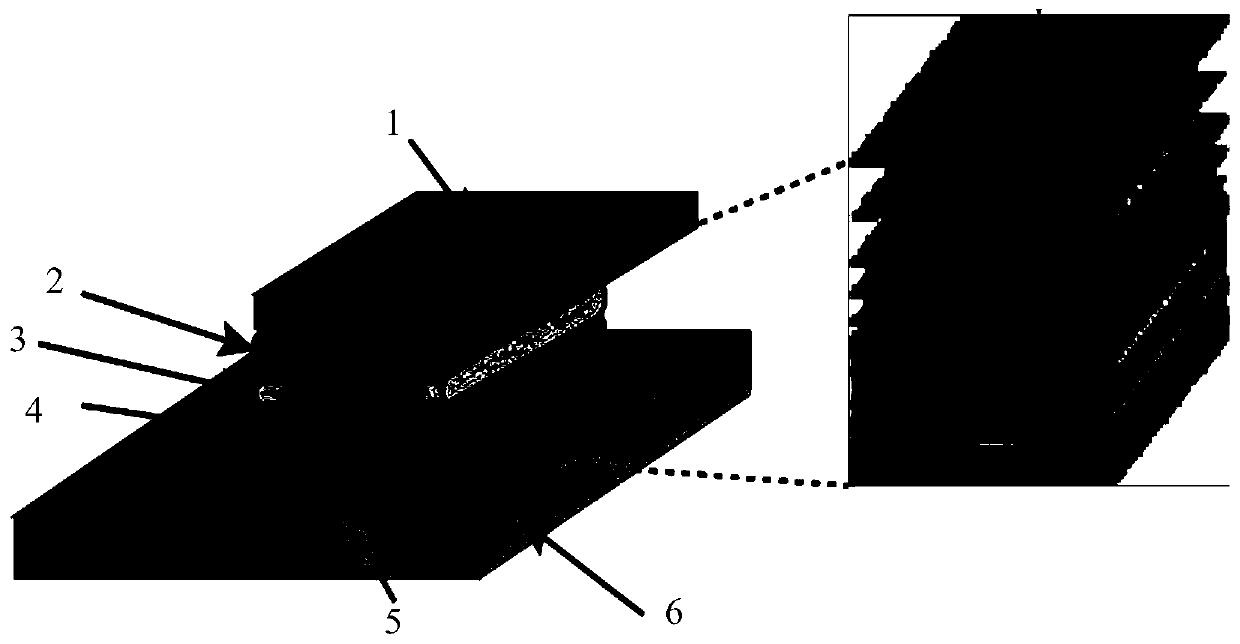

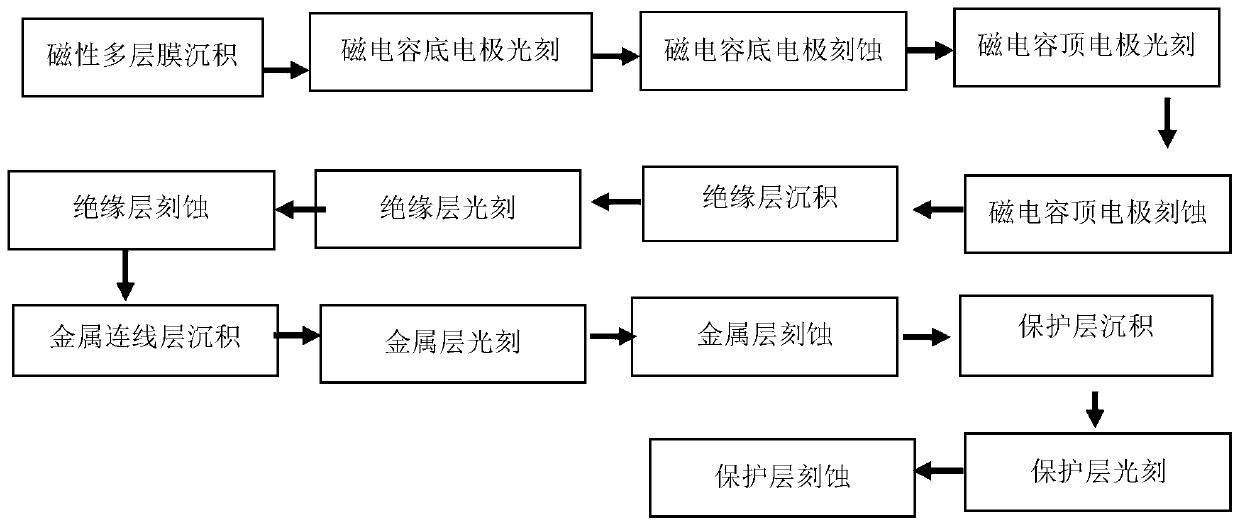

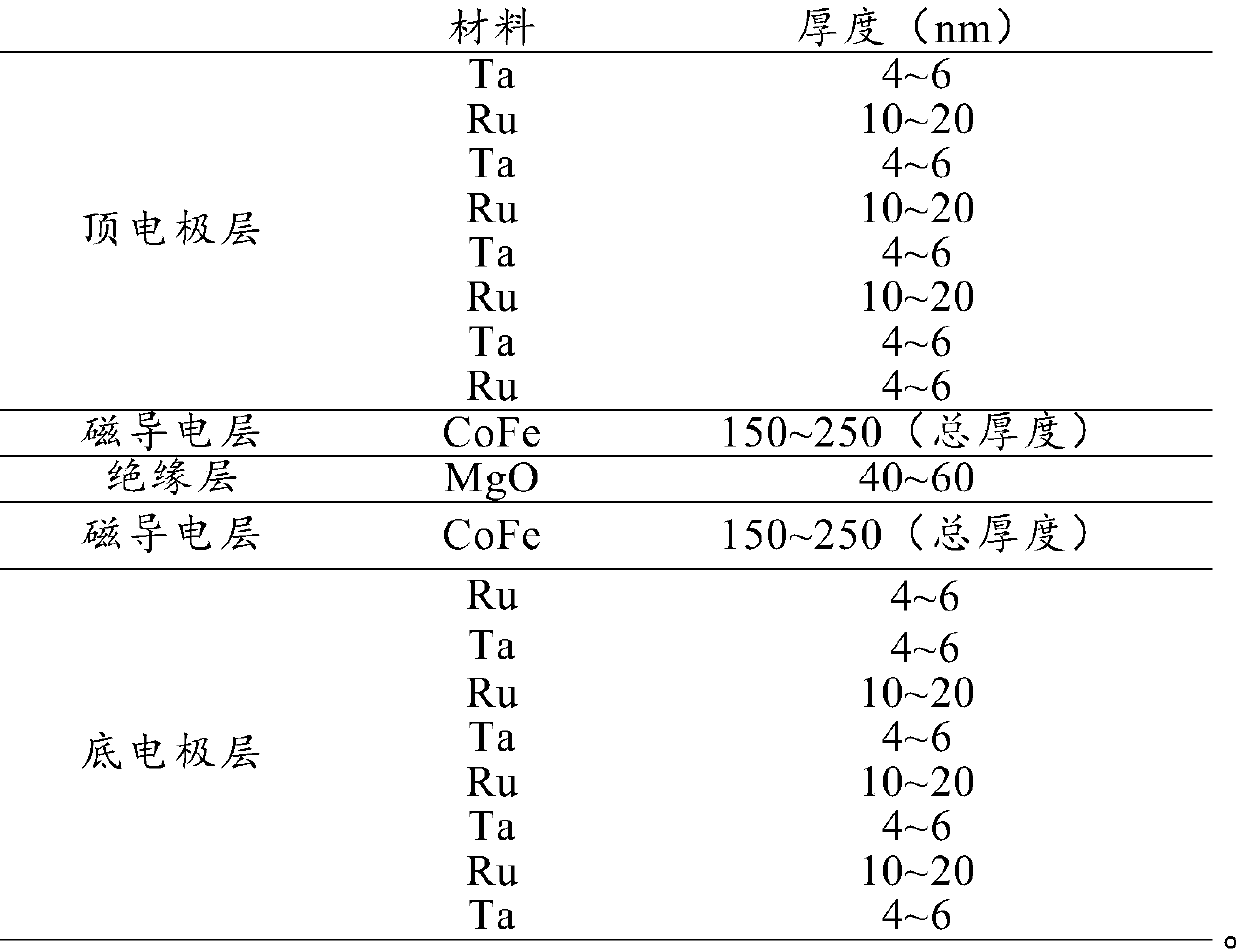

[0047] A kind of magnetic capacitance unit, such as figure 1 As shown, it includes from top to bottom: top electrode layer 1, magnetic conductive layer 2, insulating layer 3, magnetic conductive layer 4, bottom electrode layer 5. The magnetic conductive layers 2 and 4 have the same structure as the magnetic conductive layer of embodiment 2. . The composition and thickness of each layer are as follows.

[0048]

[0049] Preferably, the length of the magnetic capacitor unit is 1.0-1.6 μm, and the width is 0.8-1.0 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com