Aclinal stirring friction welding method for AZ31 magnesium alloy sheet and stirring head

A technology of friction stir and welding methods, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of low mechanical properties and deformation of welded joints, avoid tissue defects, reduce complexity, and increase friction surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Step 1: Mechanically grind and polish the 1mm-thick commercial AZ31 magnesium alloy rolled plate to be welded butt joint surface, clean it with acetone, absolute ethanol and deionized water in sequence, and quickly dry it with a hair dryer;

[0040] Step 2: rigidly fixing the dried AZ31 magnesium alloy in step (1) on the backing plate of the friction stir welding machine;

[0041] Step 3: Using a non-inclination friction stir welding stirring head to perform a single-pass non-inclination friction stir welding process on the butt joint surface of the AZ31 magnesium alloy to be welded;

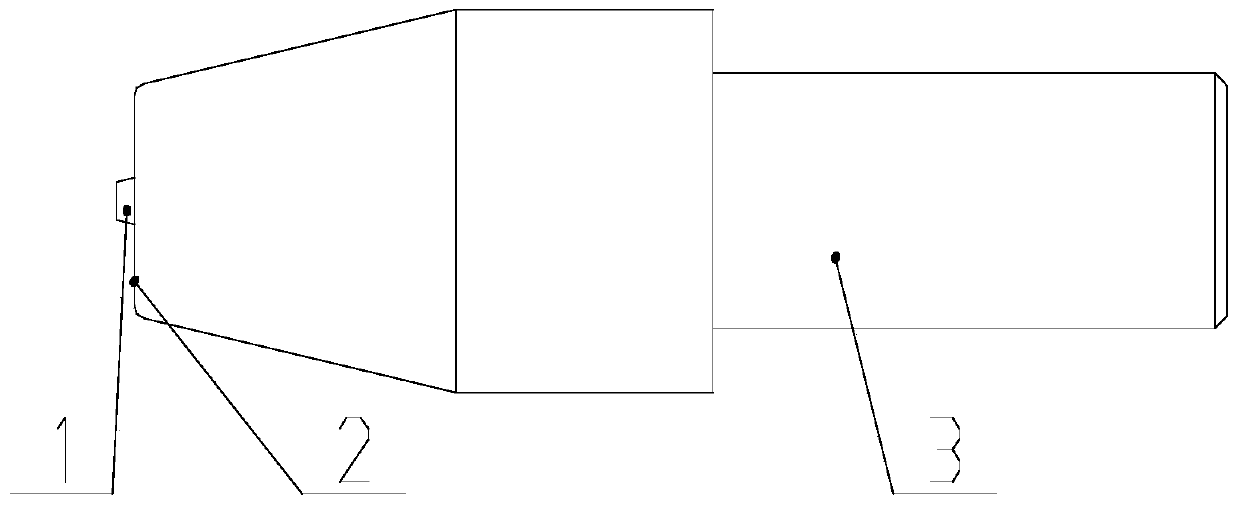

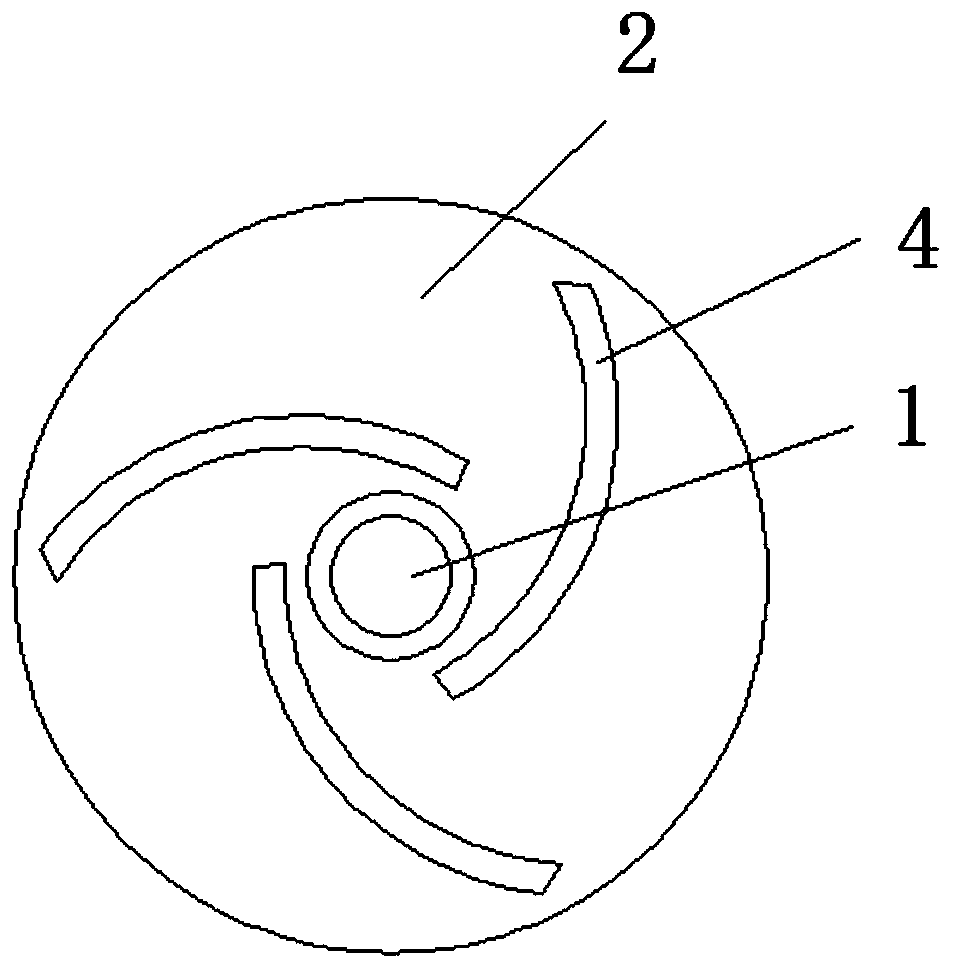

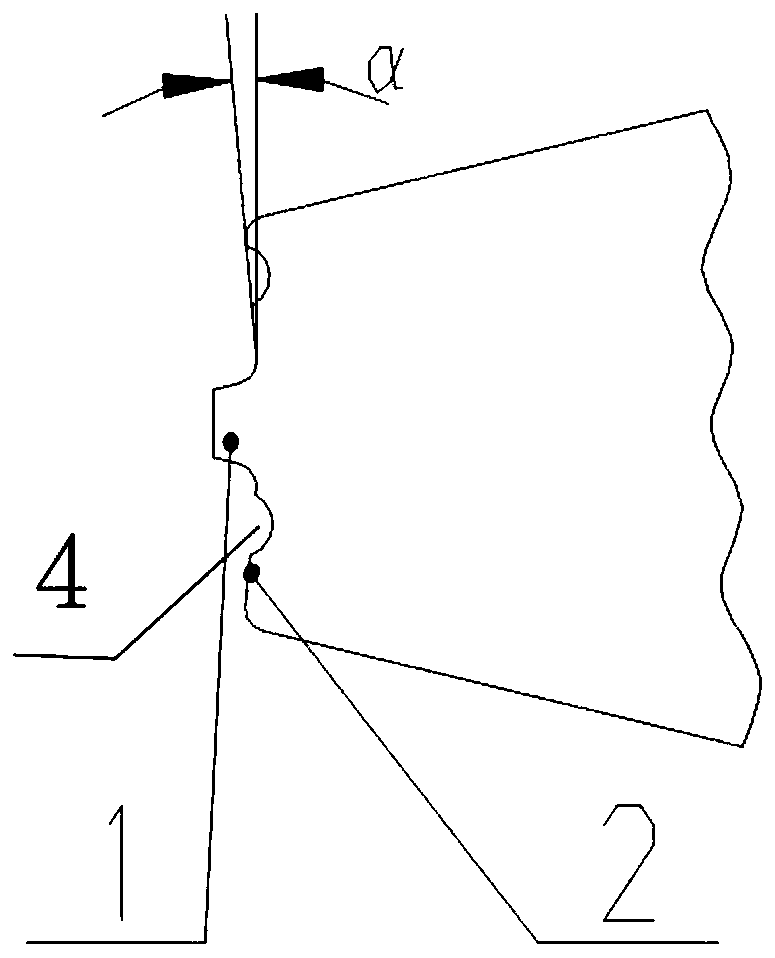

[0042] The non-inclined friction stir welding stirring head used in it can be found in Figure 1-3 shown, including:

[0043] The clamping part 3 is cylindrical;

[0044] The shaft shoulder 2 is in the shape of a circular platform, the lower bottom surface of the shaft shoulder 2 is fixedly connected with the center of the circle with the end surface of the clamping part 3, the upper bo...

Embodiment 2

[0048] Step 1: Mechanically grind and polish the 3mm-thick commercial AZ31 magnesium alloy rolled plate to be welded butt joint surface, clean it with acetone, absolute ethanol and deionized water in sequence, and quickly dry it with a hair dryer;

[0049] Step 2: rigidly fixing the dried AZ31 magnesium alloy in step (1) on the backing plate of the friction stir welding machine;

[0050] Step 3: Using a non-inclination friction stir welding stirring head to perform a single-pass non-inclination friction stir welding process on the butt joint surface of the AZ31 magnesium alloy to be welded;

[0051] The non-inclined friction stir welding stirring head used in it can be found in Figure 1-3 shown, including:

[0052] The clamping part 3 is cylindrical;

[0053] The shaft shoulder 2 is in the shape of a circular platform, the lower bottom surface of the shaft shoulder 2 is fixedly connected with the end surface of the clamping part 3 at the same circle center, the upper bottom...

Embodiment 3

[0057] Step 1: Mechanically grind and polish the 2mm thick commercial AZ31 magnesium alloy rolled plate to be welded butt joint surface, clean it with acetone, absolute ethanol and deionized water in sequence, and quickly dry it with a hair dryer;

[0058] Step 2: rigidly fixing the dried AZ31 magnesium alloy in step (1) on the backing plate of the friction stir welding machine;

[0059] Step 3: Using a non-inclination friction stir welding stirring head to perform a single-pass non-inclination friction stir welding process on the butt joint surface of the AZ31 magnesium alloy to be welded;

[0060] The non-inclined friction stir welding stirring head used in it can be found in Figure 1-3 shown, including:

[0061] The clamping part 3 is cylindrical;

[0062] The shaft shoulder 2 is in the shape of a circular platform, the lower bottom surface of the shaft shoulder 2 is fixedly connected with the center of the circle with the end surface of the clamping part 3, the upper bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Surface diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com