Cogging and forging method for improving structure uniformity of beta titanium alloy

A β-titanium alloy with uniform structure technology, which is applied in metal processing equipment and other directions, can solve problems such as unevenness, irreversibility, and coarse grains, and achieve the effect of improving structure uniformity, avoiding structure defects, and maintaining uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The specific process of this embodiment is: heat the Ti-1300 titanium alloy ingot with a diameter of Φ160 mm at 1100 ° C for 96 minutes, then place the Ti-1300 titanium alloy ingot along the length direction parallel to the axial direction of the forging anvil, and repeatedly Deform towards flattening with a flattening deformation of 30% to obtain a Ti-1300 titanium alloy forging billet, and then return to the furnace at 1000°C for 128 minutes for homogenization treatment, and finally air-cool to room temperature to obtain a Ti-1300 titanium alloy forging.

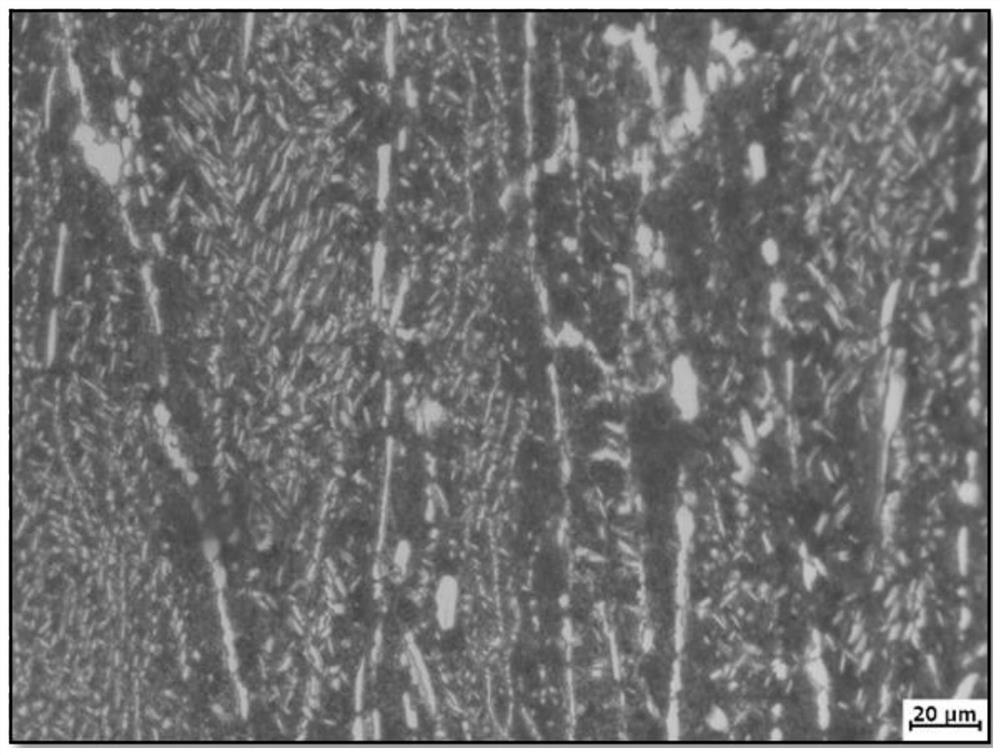

[0020] figure 1 It is the microstructure diagram of the Ti-1300 titanium alloy forging prepared by the present embodiment, from figure 1 It can be seen that the microstructure of the Ti-1300 titanium alloy forging is uniform equiaxed primary α phase dispersed in the β matrix.

Embodiment 2

[0026] The specific process of this embodiment is as follows: heat the TB8 titanium alloy ingot with a diameter of Φ160mm at 1180°C for 128min, then place the TB8 titanium alloy ingot along the length direction parallel to the axial direction of the forging anvil, and repeatedly flatten and deform it , and the flattening deformation is 40%, to obtain a TB8 titanium alloy forging billet, and then return to the furnace at 1100 ° C for 160 min for homogenization treatment, and finally air-cool to room temperature to obtain a TB8 titanium alloy forging.

Embodiment 3

[0028] The specific process of this embodiment is: heat the Ti-5553 titanium alloy ingot with a diameter of Φ160mm at 1150°C for 112min, then place the Ti-5553 titanium alloy ingot along the length direction parallel to the axial direction of the forging anvil, and repeatedly Deformation toward flattening, and the flattening deformation is 35%, to obtain Ti-5553 titanium alloy forging billet, and then return to the furnace at 1050 ° C for 144 minutes for homogenization treatment, and finally air-cooled to room temperature to obtain Ti-5553 titanium alloy forging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com