Combined core drilling system driven by downhole motor and impactor

A motor-driven, impactor technology, which is used in percussion drilling, reciprocating drilling rigs, and undisturbed core extraction devices, can solve the problems of large drill string wear, large power consumption, and easy blockage of cores. Low power consumption and low wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

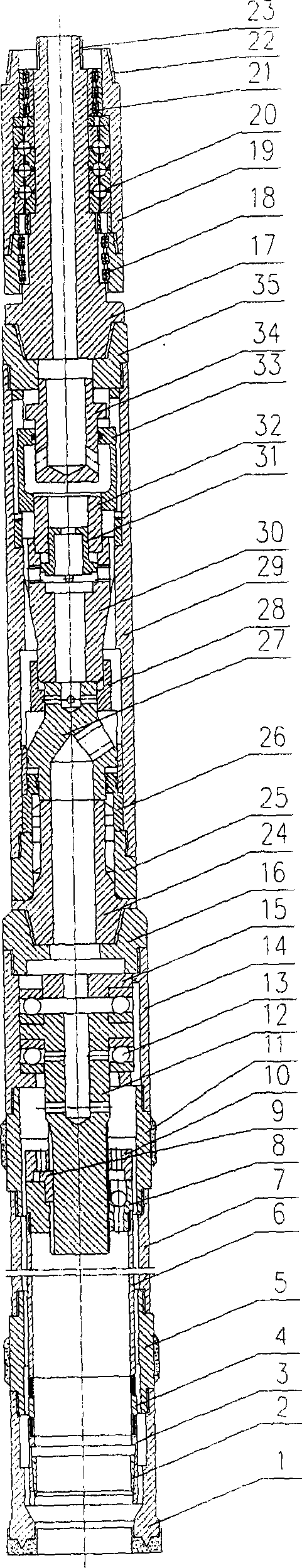

[0015] Embodiment 1: as figure 1 As shown, the downhole motor and impactor driven combined core drilling system in this embodiment is composed of a downhole motor, a valve-type double-acting impactor, a coring tool and a core bit. The upper end of the bottom hole motor is connected with the drill string, and the lower end of the bottom hole motor drive shaft 17 is connected with the upper joint 35 of the valve-type double-acting impactor by threads. The bottom-hole motor drive shaft 17 is supported in the bottom-hole motor housing 19 by the upper cemented carbide bearing 21, the thrust ball bearing 20 and the lower cemented carbide bearing 18, and the bottom-hole motor drive shaft 17 is provided with a bottom shaft Motor power shaft connection structure, here the power shaft connection structure is a threaded joint 23, and the top of the bottom hole motor drive shaft casing 19 has a bottom hole motor casing connection structure, which is a connection interface 22 here. The va...

Embodiment 2

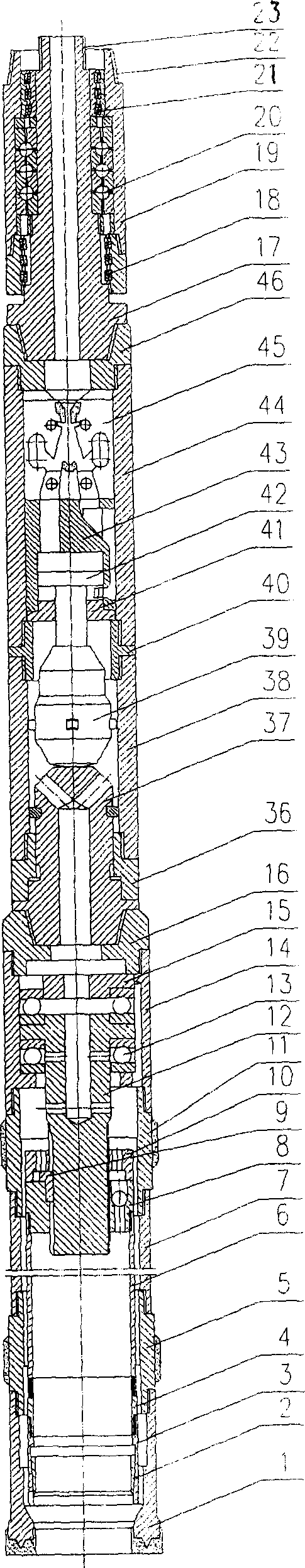

[0018] Embodiment 2: as figure 2As shown, the bottom-hole motor and impactor-driven combined core drilling system in this embodiment is similar to Embodiment 1, the difference is that in this embodiment, the bottom-hole motor and the coring tool are arranged between Jet impactor. The jet impactor is composed of a jet impactor upper joint 46, a jet element 45, an outer cylinder 44, an inner cylinder 43, a piston 42, a cylinder head 41, a middle joint 40, a hammer 39, a jet impactor outer tube 38, and an anvil. Sub-under joint 37 and octagonal cover 36 constitute. The lower end of the drive shaft 17 of the bottom hole motor is threaded with the upper joint 46 of the jet impactor; the lower joint 37 of the anvil of the jet impactor is threaded with the upper joint 16 of the upper end of the core drilling tool.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com