Lignin based phenolic resin and preparation and applications thereof

A phenolic resin and lignin-based technology, applied in the direction of aldehyde/ketone condensation polymer adhesives, adhesive types, adhesives, etc., can solve the problems of reduced curing temperature and shortened curing time of phenolic resins, and reduce the curing temperature , Reduce curing time, shorten the effect of curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

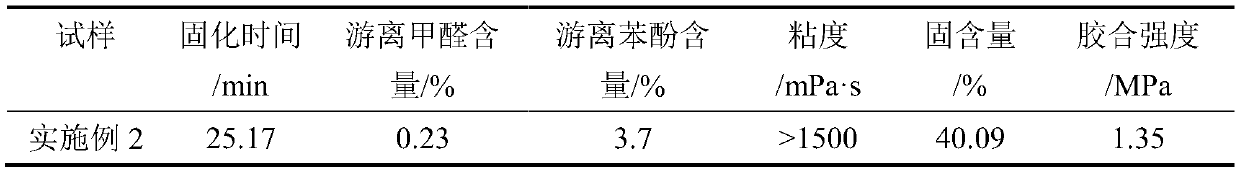

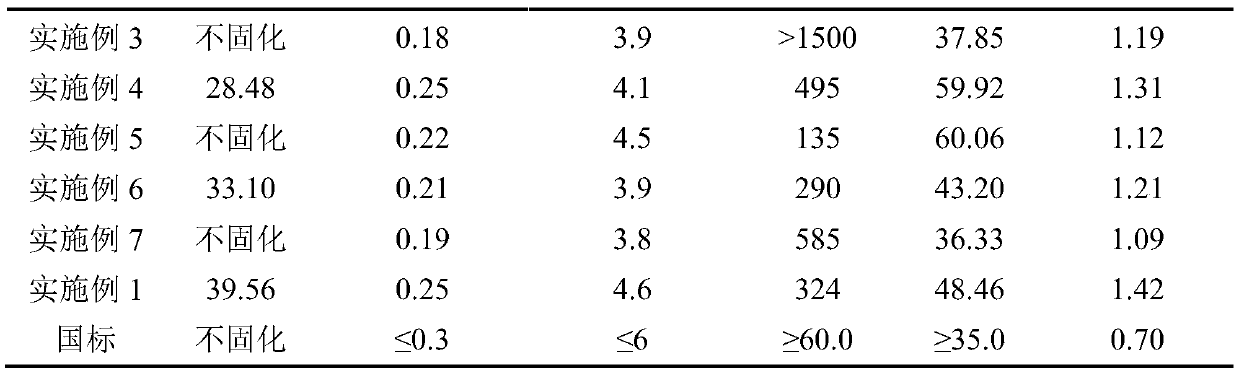

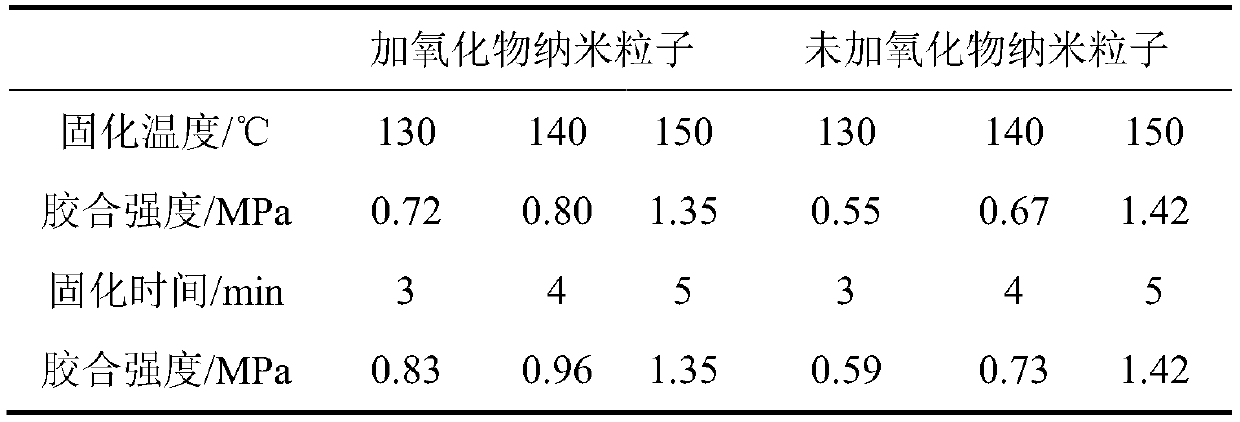

[0040] In this example, as a comparative example, 6 g of lignin and 9 g of phenol were added to a 500 mL three-necked flask and reacted in an oil bath at room temperature for 2 hours to obtain phenolated lignin. Then the phenol-formaldehyde ratio is 1:1.3, drop the formaldehyde with the constant pressure dropping funnel, first add 80% of the total amount of formaldehyde, and raise the temperature to 60°C for 1 hour. Then add the remaining 20% formaldehyde and NaOH (NaOH is 4% of the lignin mass), and react at 80° C. for 2 hours to obtain a lignin-based phenolic resin.

[0041] Determination of the properties of the prepared lignin-based phenolic resin after being prepared into an adhesive shows that the free formaldehyde content is 0.25%, the bonding strength is 1.42MPa, the solid content is 48.46%, the free phenol content is 4.6%, and the viscosity is 324mPa. s.

Embodiment 2

[0043] Add 6g of lignin and 9g of phenol into a 500mL three-necked flask and react in an oil bath at room temperature for 2 hours to obtain phenolated lignin. Then the phenol-formaldehyde ratio is 1:1.3, drop the formaldehyde with the constant pressure dropping funnel, first add 80% of the total amount of formaldehyde, and raise the temperature to 60°C for 1 hour. Then add remaining 20% formaldehyde, catalyst NaOH (NaOH is 4% of lignin quality) and catalyst molybdenum oxide nanoparticles (average particle diameter is 10nm, molybdenum oxide is 10% of the sum of NaOH and molybdenum oxide quality), at 80 Reaction at ℃ for 2h to obtain lignin-based phenolic resin.

Embodiment 3

[0045] The lignin-based phenolic resin was prepared according to the method of Implementation 2, except that the molybdenum oxide nanoparticles accounted for 30% of the total mass of the catalyst, and the average particle diameter of the molybdenum oxide nanoparticles was 50nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com