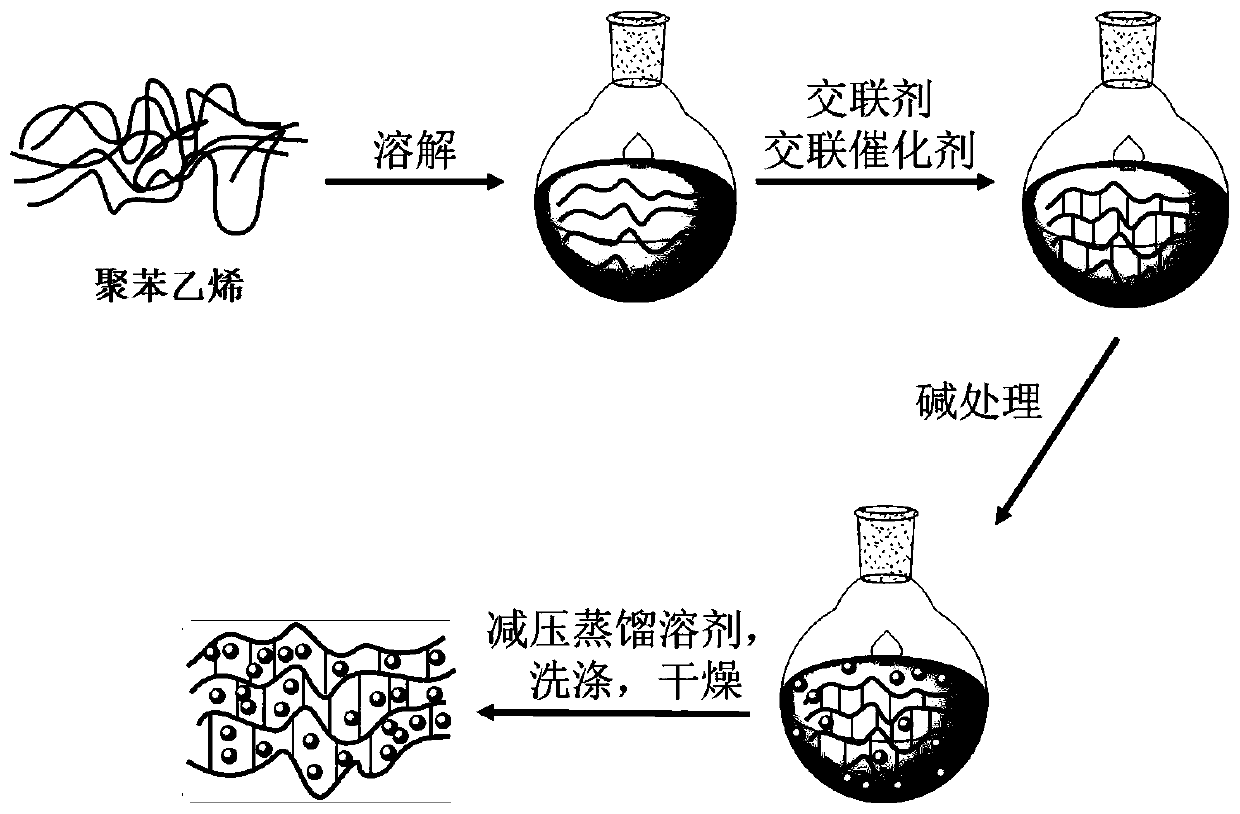

A preparation method of hypercrosslinked polystyrene loaded organic phase change material and the composite phase change material prepared therefrom

A polystyrene and organic phase technology, applied in the field of energy storage, can solve the problems of liquid phase leakage and low thermal conductivity of organic phase change materials, and achieve the effects of high-efficiency coating, simple preparation process, and easy popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Add 1.5g polystyrene and 30mL 1,2-dichloroethane into a 100mL round bottom flask, place the flask in a magnetic stirring water bath and stir until the polystyrene is completely dissolved, then add 15g paraffin (phase transition temperature is 5 degree), heat and stir at 50°C until the paraffin is completely dissolved, add 3.3g of dimethoxymethane, add 1.125g of ferric chloride, heat and stir at 50°C for 12 hours, take out the reactant, and place it in a rotary evaporator Remove excess solvent by evaporation. Dissolve the solid after vacuum distillation in absolute ethanol, add ammonia water to adjust the pH of the solution to ≥ 10, put the resulting mixture in a 30kW ultrasonic cell pulverizer and sonicate for 0.5 hours, take it out and put it in a magnetic stirring water bath, adjust the temperature at 50°C with a rotational speed of 600r / min, heat and stir for 10 hours, take the resulting mixture out and place it in a rotary evaporator, evaporate the solvent, and then...

Embodiment 2

[0046] Add 1.5g of polystyrene and 30mL of methylene chloride in a 100mL round bottom flask, place the flask in a magnetic stirring water bath and stir until the polystyrene is completely dissolved, then add 7.5g of paraffin (phase transition temperature is 25 degrees), 50 Heat and stir at ℃ until the paraffin is completely dissolved, add 1.09g of dimethoxymethane, add 1.912g of aluminum trichloride, heat and stir at 50℃ for 12 hours, take out the reactant, and evaporate it in a rotary evaporator Excess solvent. Dissolve the solid after distillation under reduced pressure in absolute ethanol, add sodium hydroxide to adjust the pH of the solution to ≥ 10, place the resulting mixture in a 20kW ultrasonic cell pulverizer and sonicate for 0.5 hours, take it out and place it in a magnetically stirred water bath, Adjust the temperature to 50°C, rotate at 600r / min, heat and stir for 10 hours, take the resulting mixture out and place it in a rotary evaporator, evaporate the solvent, a...

Embodiment 3

[0049]Add 1.5g of polystyrene and 30mL of chloroform to a 100mL round bottom flask, place the flask in a magnetic stirring water bath and stir until the polystyrene is completely dissolved, then add 4.5g of paraffin (phase transition temperature is 30 degrees), 60 Heat and stir at ℃ until the paraffin is completely dissolved, add 1.7739g of 1,2-dichloroethane, add scandium trifluoromethanesulfonate 7.0577g, heat and stir at 60℃ for 20 hours, take out the reactant, and place in a rotating In an evaporator, the excess solvent was evaporated. Dissolve the solid after vacuum distillation in absolute ethanol, add potassium hydroxide to adjust the pH of the solution to ≥ 10, place the resulting mixture in a 50kW ultrasonic cell pulverizer for 1 hour, take it out and place it in a magnetic stirring water bath, Adjust the temperature to 60°C, rotate at 600r / min, heat and stir for 16 hours, take out the resulting mixture and place it in a rotary evaporator, evaporate the solvent, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com