A silicon carbide fiber with radial gradient distribution of heterogeneous elements and its preparation method and equipment

A technology of silicon carbide fiber and radial gradient, which is applied in the fields of fiber chemical characteristics, rayon manufacturing, textiles and paper making, etc. It can solve the problems of unfavorable large-scale production, complicated preparation process, and insufficient utilization of the properties of each element.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

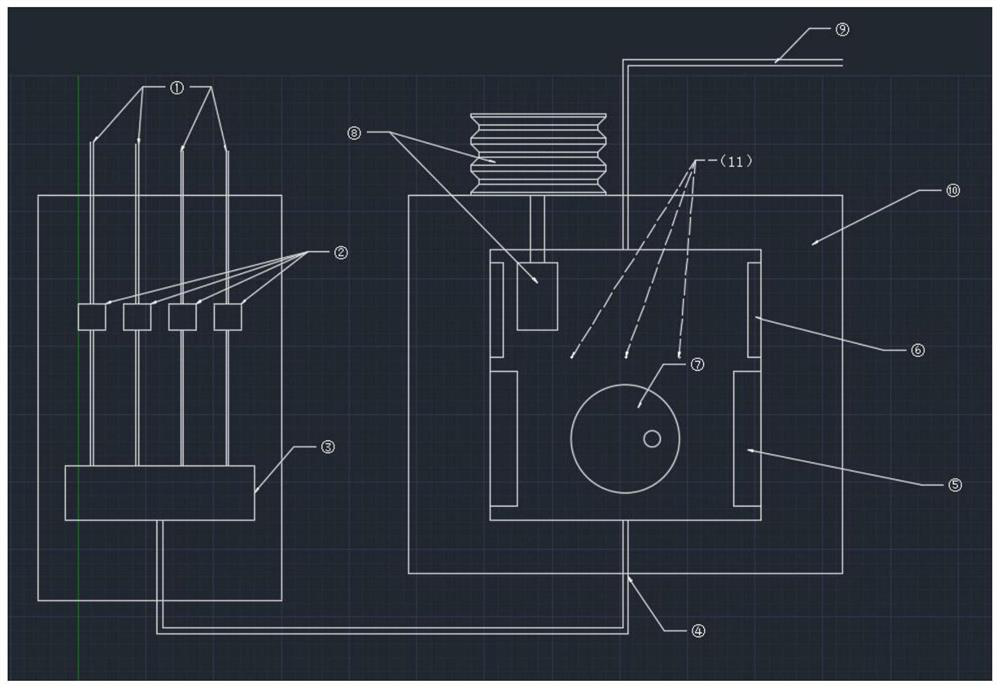

Image

Examples

Embodiment 1

[0055] First place the polycarbosilane precursor in the non-melting treatment device, evacuate the non-melting treatment device, then fill it with argon, repeat the above gas replacement 3 times, then heat the non-melting treatment device to 420°C, and pass through the Mixed gas in the mixed gas tank: boron trichloride, beryllium chloride, argon, among which, by volume ratio, boron trichloride: beryllium chloride: argon = 1:3:2, in ultrasonic (ultrasonic frequency is 500KHZ ) under the action of 420°C for 2 hours, carry out the first-stage non-melting treatment, and then fill the non-melting treatment device with pure argon for 20 minutes, so that the entire non-melting treatment equipment is filled with argon, and then pass it into the mixed gas tank to mix Gases: boron trichloride, beryllium chloride, argon, among which, by volume ratio, boron trichloride: beryllium chloride: argon = 3:1:2, under the action of ultrasound (ultrasonic frequency is 400KHZ) React at 420°C for 4 ...

Embodiment 2

[0059] First place the polycarbosilane precursor in the non-melting treatment device, evacuate the non-melting treatment device, then fill it with argon, repeat the above gas replacement 3 times, then heat the non-melting treatment device to 450°C, and pass through the Mixed gas in the mixed gas tank: boron trichloride, beryllium chloride, argon, among which, in terms of volume ratio, boron trichloride: beryllium chloride: argon = 1:4:2, in ultrasonic (ultrasonic frequency is 560KHZ ) under the action of 450°C for 2 hours, carry out the first-stage non-melting treatment, and then fill the non-melting treatment device with pure argon for 20 minutes, so that the entire non-melting treatment equipment is filled with argon, and then pass it into the mixed gas tank to mix Gases: boron trichloride, beryllium chloride, argon, among which, by volume ratio, boron trichloride: beryllium chloride: argon = 4:1:2, under the action of ultrasound (ultrasonic frequency is 500KHZ) React at 450...

Embodiment 3

[0063] First place the polycarbosilane precursor in the non-melting treatment device, evacuate the non-melting treatment device, then fill it with argon, repeat the above gas replacement 3 times, then heat the non-melting treatment device to 500°C, and pass through the Mixed gas in the mixed gas tank: boron trichloride, beryllium chloride, argon, among which, by volume ratio, boron trichloride: beryllium chloride: argon = 2:5:3, in ultrasonic (ultrasonic frequency is 700KHZ ) under the action of 500°C for 2 hours, carry out the first-stage non-melting treatment, and then fill the non-melting treatment device with pure argon for 20 minutes, so that the whole non-melting treatment equipment is filled with argon, and then pass it into the mixed gas tank to mix Gases: boron trichloride, beryllium chloride, argon, among them, by volume ratio, boron trichloride: beryllium chloride: argon = 4:2:3, under the action of ultrasound (ultrasonic frequency is 600KHZ) React at 500°C for 4 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com