Purification technology of colloid compound

A technology of colloidal compounds and processes, which is applied in the field of purification process of colloidal compounds, can solve the problems of gastric mucosal damage, skin aging, reduction, etc., and achieve the effects of high sodium removal efficiency, avoiding waste, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

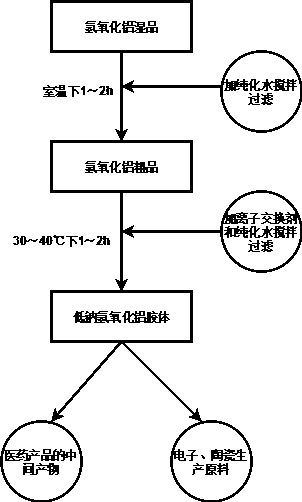

Image

Examples

Embodiment 1

[0034] Weigh 40kg of self-made aluminum hydroxide wet product (aluminum hydroxide content is about 16%, sodium content is about 3.2%), put the aluminum hydroxide wet product into the reaction kettle, add 240kg of purified water, stir at room temperature for 1h, Filter the crude aluminum hydroxide, then add 240kg of purified water and 5.6kg of ammonium acetate, stir at 35°C for 1 hour, filter to obtain the purified low-sodium aluminum hydroxide colloid, the dry yield is about 90% after testing, and the sodium content About 100ppm.

Embodiment 2

[0036] Weigh 55kg of self-made aluminum hydroxide wet product (aluminum hydroxide content is about 16%, sodium content is about 3.4%), put the aluminum hydroxide wet product into the reaction kettle, add 266kg of purified water, stir at room temperature for 1h, Filter the crude aluminum hydroxide, then add 266kg of purified water and 5.2kg of diammonium hydrogen phosphate, stir at 30°C for 1 hour, filter to obtain the purified low-sodium aluminum hydroxide colloid, and the dry yield is about 93% after testing. The sodium content is about 102ppm.

Embodiment 3

[0038] Weigh 50kg of self-made aluminum hydroxide wet product (aluminum hydroxide content is about 17%, sodium content is about 3.5%), put the aluminum hydroxide wet product into the reaction kettle, add 260kg of purified water, stir at room temperature for 1h, Filter the crude product of aluminum hydroxide, then add 260kg of purified water and 6.2kg of ammonium carbonate, stir at 30°C for 1 hour, filter to obtain the purified low-sodium aluminum hydroxide colloid, the dry yield is about 94% after testing, the sodium content About 95ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com