Phenolic hydroxyl group-containing resin and resist material

A technology of phenolic hydroxyl resin and hydrocarbon group, applied in the field of phenolic hydroxyl resin, can solve the problems of low coatability, low fluidity, insufficient surface smoothness, etc., and achieve high heat resistance and dry etching resistance, fluidity excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

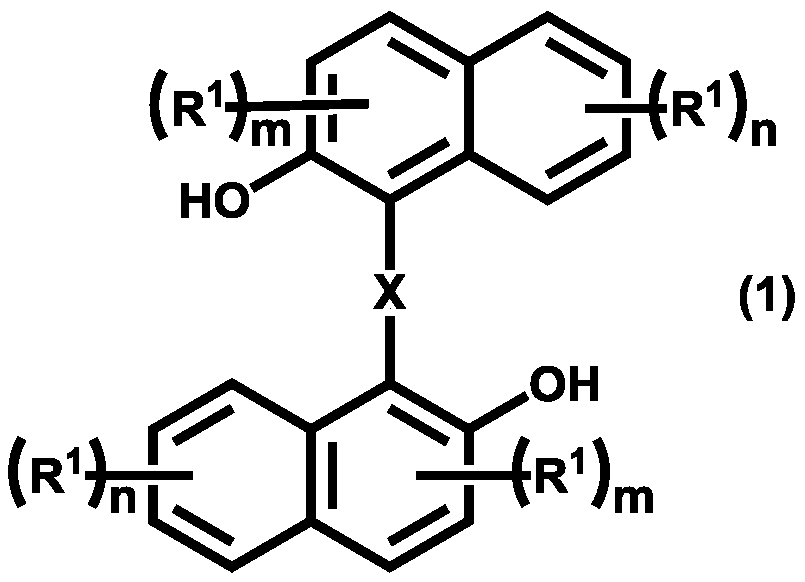

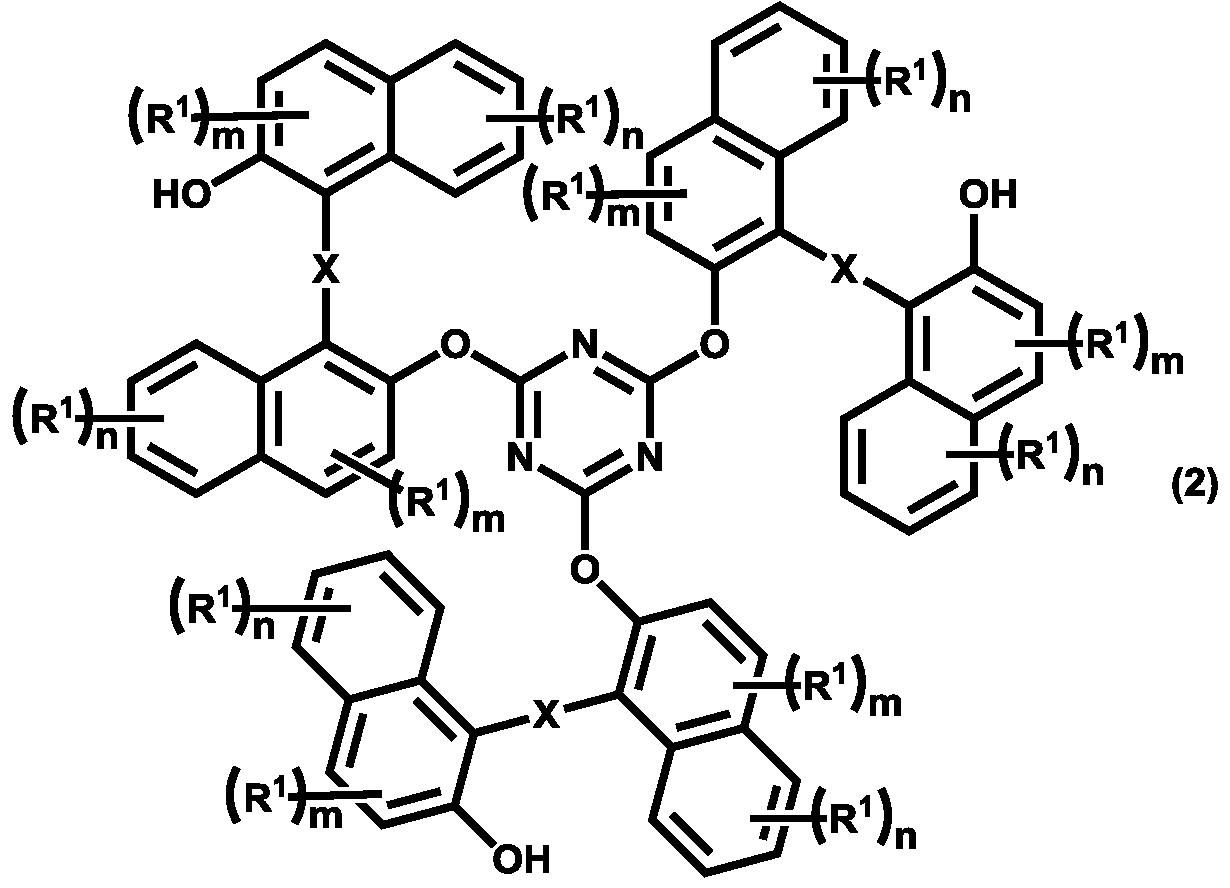

[0121] The manufacture of embodiment 1 phenolic hydroxyl resin (1)

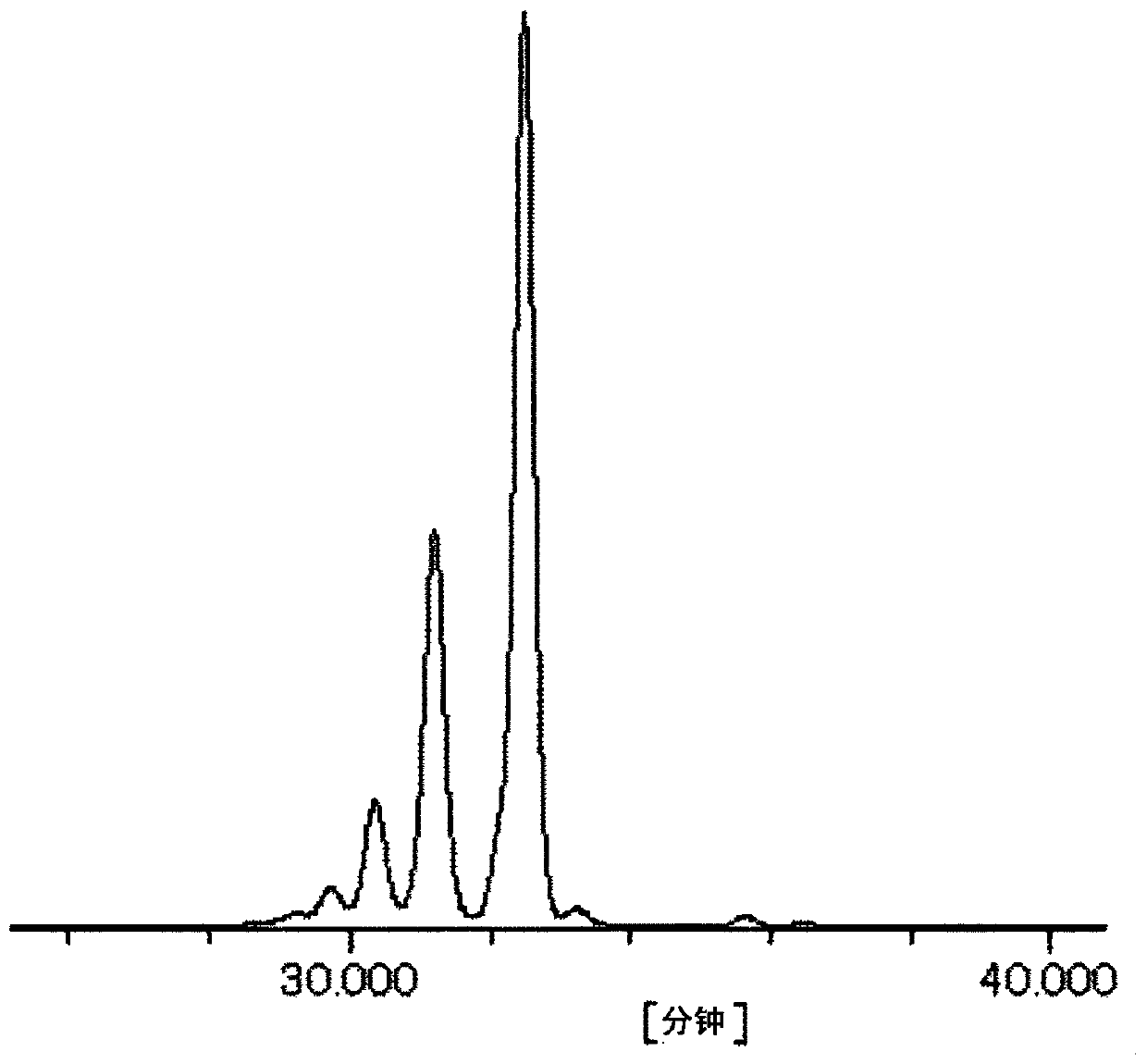

[0122]152 parts by mass of the bis-naphthol compound (a1), 31 parts by mass of cyanuric chloride, and 500 parts by mass of methyl ethyl ketone obtained before were charged into a 1000-ml 4-necked flask equipped with a condenser, and stirred and dissolved. After heating to about 50°C to 70°C, 52 parts by mass of triethylamine was added dropwise over 60 minutes. After completion of the dropwise addition, stirring was continued at 70° C. for 5 hours. Next, 200 parts by mass of water was added to dissolve triethylamine hydrochloride, and liquid separation was performed, and the water layer was discarded. Furthermore, after washing twice with the same amount of water, the methyl ethyl ketone was recovered by distillation, and the mixed solvent of methanol / water=10 / 1 (mass ratio) was used for reprecipitation twice, and the precipitate was recovered and dried under reduced pressure to obtain 113 parts by mass of p...

Embodiment 2

[0123] The manufacture of embodiment 2 phenolic hydroxyl resin (2)

[0124] In Example 1, except having changed the addition amount of the bis-naphthol compound (a1) from 152 mass parts to 114 mass parts, it carried out similarly to Example 1, and obtained 92 mass parts of phenolic hydroxyl-containing resins (2). The obtained phenolic hydroxyl group-containing resin (2) has a number average molecular weight (Mn) of 1,013, a weight average molecular weight (Mw) of 1,252, a polydispersity coefficient (Mw / Mn) of 1.24, and a number average molecular weight (Mn) of 500 or less The content is 2.8%. In addition, the content of the polynuclear compound (A) in the phenolic hydroxyl group-containing resin (2)) was 37.9%, and the total content of the polynuclear compound (A) and the compound (B) was 61.5%.

Embodiment 3、4 and comparative example 1、2

[0130] The phenolic hydroxyl group-containing resin obtained in Examples 1 and 2 and Comparative Production Examples 1 and 2 were evaluated in the following manner. The results are shown in Table 1.

[0131] Manufacture of thermosetting compositions

[0132] 1.6 parts by mass of resin containing phenolic hydroxyl group, 0.4 parts by mass of curing agent ("1,3,4,6-tetrakis(methoxymethyl) glycoluril" manufactured by Tokyo Chemical Industry Co., Ltd.), 0.1 part by mass of p-toluenesulfonic acid It was dissolved in 100 parts by mass of propylene glycol monomethyl ether acetate, and this was filtered through a 0.2 μm membrane filter to obtain a thermosetting composition.

[0133] Evaluation of sublimation resistance

[0134] The previously obtained thermosetting composition was coated on a 5-inch silicon wafer with a spinner, and dried on a hot plate at 110° C. for 180 seconds in an environment having an oxygen concentration of 20% by volume. Next, heat curing was performed at 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com