Production method of corrosion-resistant high-conductivity fuel cell metal bipolar plate

A technology of metal bipolar plates and production methods, which is applied to fuel cell parts, fuel cells, electrochemical generators, etc., can solve the problems of no manufacturing method angle, cumbersome process, low production capacity, etc., and achieve accelerated industrialization process, shorten the process flow, and improve the effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

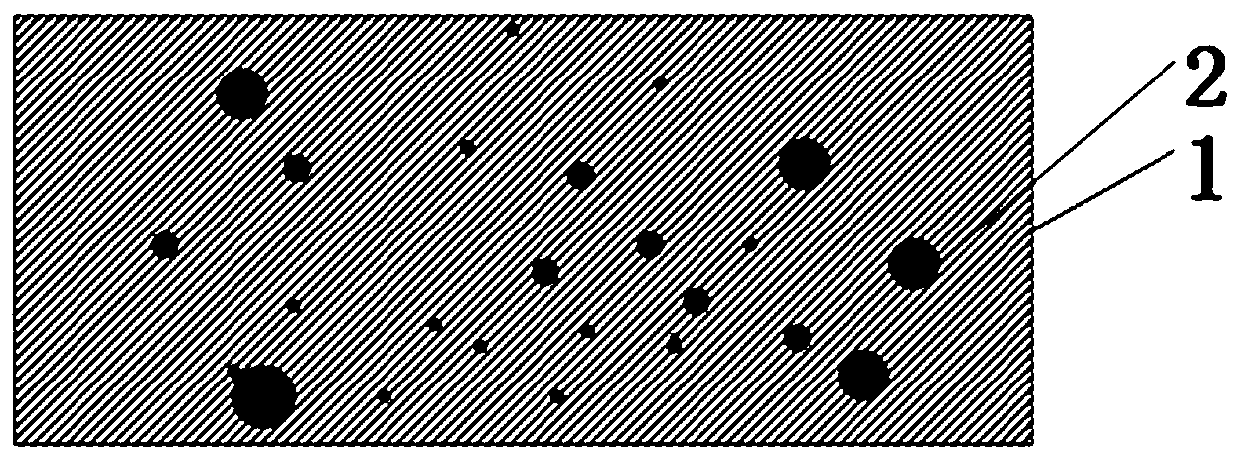

Embodiment 1

[0027] A 316L stainless steel substrate with a certain corrosion resistance and uniform thickness was selected, and the stainless steel substrate was ultrasonically cleaned in ethanol and water to remove surface grease and surface debris. Fix the stainless steel substrate on the hanger, transport it to the working position through the transmission guide rail, then close the reaction chamber, and the pumping system starts to vacuum; when the vacuum is pumped to 1Pa, the heater will heat; when the heating temperature reaches the required temperature , keep warm for a period of time, and then pass the reaction gas into the cavity through the gas circuit and air holes, and control the vacuum degree required by the process through the pumping system; Reactive gas; control the reaction time, when the deposited carbon thickness meets the requirements, turn off the RF power supply of the RF electrode, and deposit a speckle-shaped conductive material with a diameter of 1-2500nm and a th...

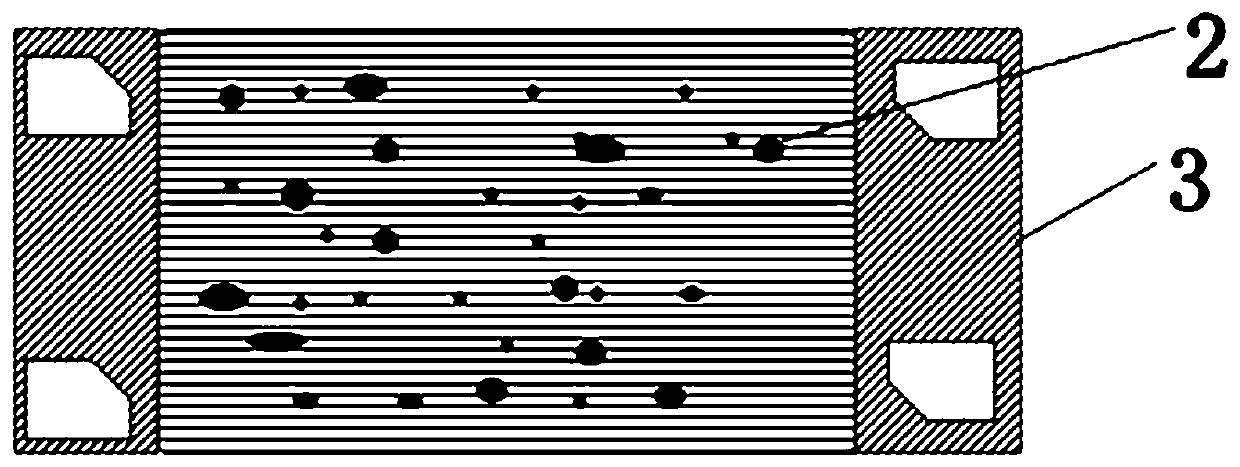

Embodiment 2

[0030] Select a titanium plate with good corrosion resistance and uniform thickness, and ultrasonically clean the titanium plate in ethanol and water respectively to remove surface grease and surface debris. Fix the titanium plate on the hanger, transport it to the working position through the transmission guide rail, then close the reaction chamber, and the exhaust system starts to vacuum; when the vacuum reaches 4Pa, the heater will heat; when the heating temperature reaches the required temperature , keep warm for a period of time, then pass plasma gas into the cavity through the gas circuit and air holes, and control the vacuum degree required by the process through the pumping system; when the cavity pressure is stable, adjust the power of the arc to match the powder supply speed, adjust The spraying distance and spraying angle ensure that the powder is evenly coated on the substrate, and the relative movement speed between the spray gun and the workpiece is controlled. Wh...

Embodiment 3

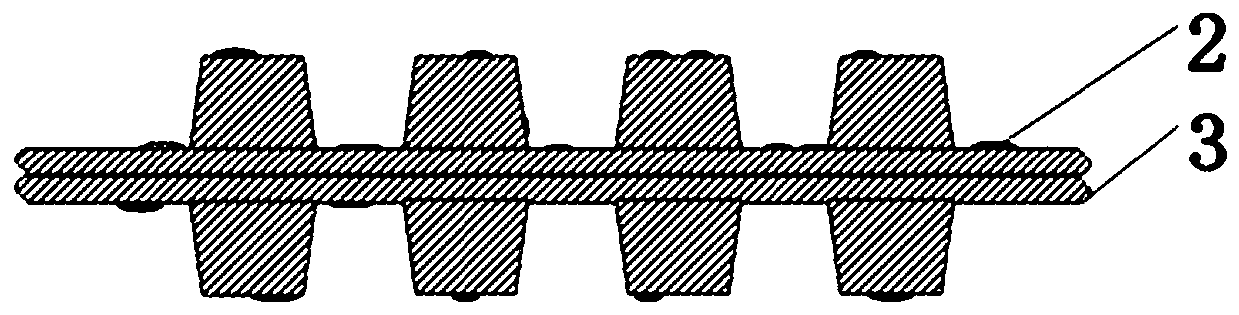

[0033] A titanium plate with good corrosion resistance and uniform thickness was selected, and the titanium substrate was ultrasonically cleaned in ethanol and water to remove surface grease and surface debris. Fix the titanium plate on the hanger, spray metal particles and nano-gold onto the surface of the titanium plate by thermal spraying, control the reaction time for 5-10 minutes, and spray the speed of 0.5m min -1, To 5m min-1, the nano-gold particles sprayed on the surface of the titanium plate have a diameter of 2.5-2500nm, a thickness of 550-2500nm, and a speckle-like gold spot with a coverage rate of 5%. Integrate into one, and finally form a bipolar plate through external packaging.

[0034] Performance test: The contact resistance test is carried out on the sample. When the surface density of the nano-gold powder particles reaches about 5%, the contact resistance is 3.37mΩ·cm under the pressure of 0.6Mpa 2 , has reached less than 10mΩ·cm 2 application standards. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com