Anti-aging PC/ABS alloy plastic and preparation method thereof

An alloy plastic and anti-aging technology, which is applied in the field of anti-aging PC/ABS alloy plastic and its preparation, can solve the problems of unsatisfactory anti-aging performance, improve long-term thermal oxidation and weather resistance, improve stability, and increase mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

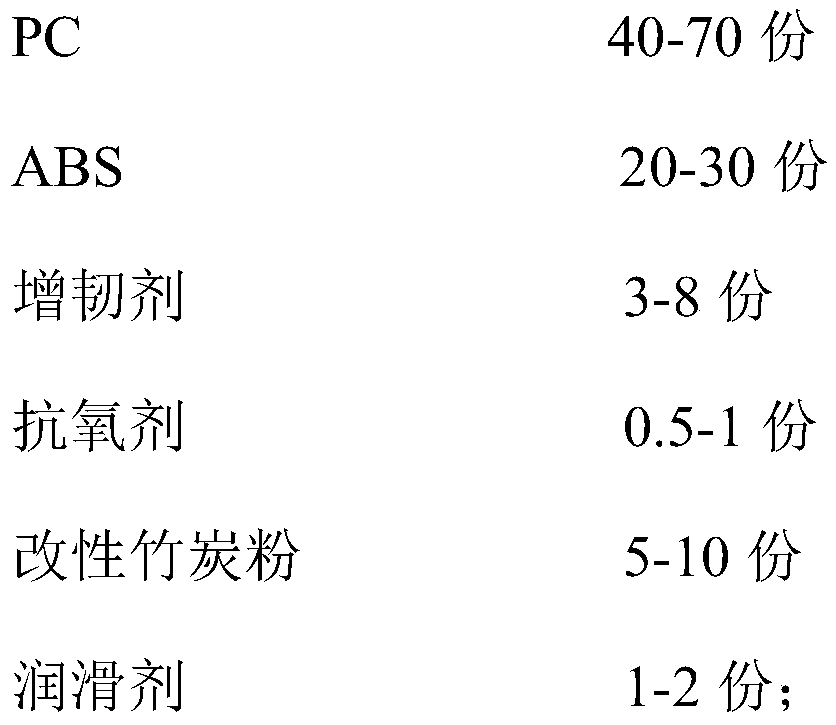

[0023] An aging-resistant PC / ABS alloy plastic, the raw materials of which are composed of the following components by weight: 40 parts of PC, 30 parts of ABS, 3 parts of MBS toughening agent, 4,4'-thiobis(6-tert-butyl base-3-methylphenol) 0.5 parts, modified bamboo charcoal powder 5 parts, lubricant 1 part.

[0024] Modified bamboo charcoal powder is obtained by modifying bamboo charcoal powder with copper sulfate after high-temperature activation. The specific preparation process is as follows: pass nitrogen into the bamboo charcoal powder, heat up to 500°C at a rate of 3°C / min, keep warm for 2 hours, and cool to 80°C , air-cooled to room temperature to obtain activated bamboo charcoal powder; put activated bamboo charcoal powder into a copper sulfate solution with a concentration of 10g / L for immersion, the immersion temperature is 20°C, the bath ratio of activated bamboo charcoal powder and copper sulfate solution is 1:30, and the immersion time is 4h.

[0025] The prepar...

Embodiment 2

[0029] An aging-resistant PC / ABS alloy plastic, its raw materials are composed of the following components by weight: 70 parts of PC, 20 parts of ABS, 8 parts of MBS type toughening agent, 1 part of 2,6-di-tert-butylphenol, modified 10 parts of bamboo charcoal powder, 2 parts of lubricant.

[0030] Modified bamboo charcoal powder is obtained by modifying bamboo charcoal powder with copper sulfate after high-temperature activation. The specific preparation process is: pass nitrogen into the bamboo charcoal powder, heat up to 600°C at a speed of 5°C / min, hold for 1 hour, and cool to 90°C , air-cooled to room temperature to obtain activated bamboo charcoal powder; put activated bamboo charcoal powder into the copper sulfate solution with a concentration of 12g / L for immersion, the immersion temperature is 30°C, the bath ratio of activated bamboo charcoal powder and copper sulfate solution is 1:25, and the immersion time is 3h.

[0031] The preparation method of described aging-r...

Embodiment 3

[0035] An aging-resistant PC / ABS alloy plastic, its raw materials are composed of the following components by weight: 55 parts of PC, 25 parts of ABS, 5 parts of MBS toughening agent, 4,4'-thiobis(6-tert-butyl base-3-methylphenol) 0.2 parts, 2,6-di-tert-butylphenol 0.6 parts, modified bamboo charcoal powder 8 parts, lubricant 1.5 parts.

[0036] Modified bamboo charcoal powder is obtained by modifying bamboo charcoal powder with copper sulfate after high-temperature activation. The specific preparation process is as follows: nitrogen gas is introduced into the bamboo charcoal powder, the temperature is raised to 550°C at a speed of 4°C / min, the temperature is kept for 1.5h, and cooled to 85°C. ℃, air-cooled to room temperature to obtain activated bamboo charcoal powder; put the activated bamboo charcoal powder into the copper sulfate solution with a concentration of 11g / L for immersion, the immersion temperature is 25 ℃, the bath ratio of activated bamboo charcoal powder and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com