Preparation method and application of medical magnesium-based metal coating with stress-corrosion-resisting and self-repairing functions

A magnesium-based metal, self-healing technology, applied in coating, medical science, surgery, etc., can solve the problem of effectively inhibiting anodic dissolution stress corrosion cracking mechanism, coating components containing toxic or carcinogenic substances, hydrogen-induced stress corrosion cracking Problems such as limited restraint ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

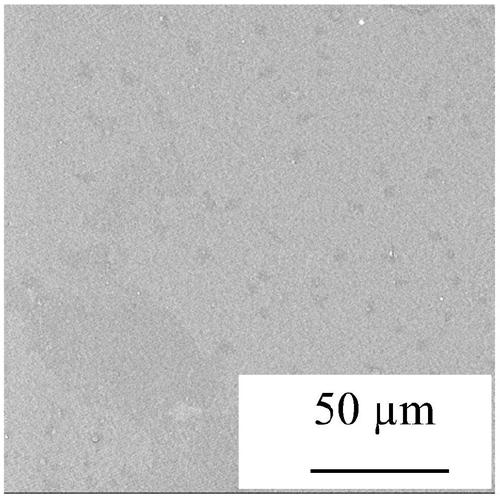

[0090] The commercially available extruded WE43 magnesium alloy is selected as the base material, and the process of preparing an anti-stress corrosion self-repairing coating on the surface of the magnesium alloy is as follows:

[0091] (1) Pretreatment: Grind the magnesium alloy with 400#, 800#, 1200#, 1500# and 2000# sandpaper (that is, mechanically polish and polish silicon carbide water sandpaper), rinse with deionized water, and then put in acetone Ultrasonic cleaning in medium for 10 minutes, then rinse with deionized water, pickle with a mixed solution of 200 mg / mL acetic acid and 60 mg / mL sodium nitrate at a final concentration of 0.5 minutes, then ultrasonically clean with deionized water for 10 minutes, deionized water Rinse, dry in a vacuum oven at 60°C, and set aside.

[0092] (2) Hydroxylation treatment: Soak the magnesium alloy obtained in step (1) in 50° C. sodium hydroxide solution of 5mol / L for 2 hours, carry out hydroxylation treatment, obtain a large amount ...

Embodiment 2

[0099] The commercially available ZK40 magnesium alloy is selected as the base material, and the process of preparing an anti-stress corrosion self-repairing coating on the surface of the magnesium alloy is as follows:

[0100] (1) Pretreatment: Grind the magnesium alloy with 400#, 800#, 1200#, 1500# and 2000# sandpaper (that is, mechanically polish and polish silicon carbide water sandpaper), rinse with deionized water, and then put in acetone Ultrasonic cleaning in medium for 10 minutes, then rinse with deionized water, pickle with a mixed solution of 200mg / mL acetic acid and 60mg / mL sodium nitrate for 0.5 minutes, then ultrasonically clean with deionized water for 10 minutes, rinse with deionized water, vacuum Dry in a drying oven at 60°C for use.

[0101] (2) Hydroxylation treatment: Soak the magnesium alloy obtained in step (1) in 3mol / L 80°C sodium hydroxide solution for 1.5 hours, carry out hydroxylation treatment, obtain a large amount of basic hydroxyl groups on the s...

Embodiment 3

[0107] The commercially available AZ31 magnesium alloy is selected as the substrate, and the process of preparing an anti-stress corrosion self-repairing coating on the surface of the magnesium alloy is as follows:

[0108] (1) Pretreatment: Grind the magnesium alloy with 400#, 800#, 1200#, 1500# and 2000# sandpaper (that is, mechanically polish and polish silicon carbide water sandpaper), rinse with deionized water, and then put in acetone Ultrasonic cleaning in medium for 10 minutes, then rinse with deionized water, pickle with a mixed solution of 200 mg / mL acetic acid and 60 mg / mL sodium nitrate at a final concentration of 0.5 minutes, then ultrasonically clean with deionized water for 10 minutes, deionized water Rinse, dry in a vacuum oven at 60°C, and set aside.

[0109] (2) Hydroxylation treatment: Soak the magnesium alloy obtained in step (1) in 3mol / L 80°C sodium hydroxide solution for 1.5 hours, carry out hydroxylation treatment, obtain a large amount of basic hydroxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com