Sulphate-attack-resistant concrete admixture and preparation method thereof

A concrete admixture and sulfate-resistant technology, which is applied in the field of concrete admixtures, can solve the problems of not fundamentally preventing external sulfate erosion, reducing mechanical properties and anti-carbonation performance, and harsh conditions for the synthesis of admixtures. The process and product itself have good environmental safety, improve the effect of sulfate corrosion resistance, and maintain the original mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

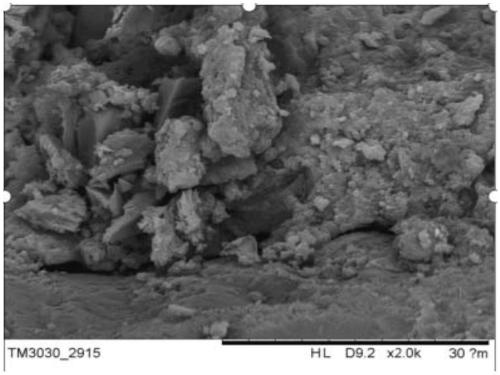

Image

Examples

Embodiment 1

[0034]The macromolecular emulsifier is polyethylene glycol 1000 monomethyl ether, which is heated and melted in the reactor, maleic anhydride is added in an equimolar ratio, the temperature is controlled at 60°C to 65°C, and the reaction is carried out for 5 hours to obtain the unsaturated carboxylic acid polymer. Ethylene glycol ether ester macromer, let it stand and cool for later use; in addition, mix acrylic acid and butyl acrylate with a total mole number of 1 in a ratio of 7:3 to form a mixed monomer, and add the molar ratio of the mixed monomer to the aqueous solution Potassium persulfate of 0.03 is used as a thermal decomposition type initiator, and an unsaturated carboxylic acid polyethylene glycol ether ester macromonomer whose molar number is 0.4 of the molar number of the aforementioned mixed monomers is dissolved in water, heated to 60° C., and controlled Quickly add the mixed monomer, drop it within 120 minutes, then keep it warm for 120 minutes, lower the tempera...

Embodiment 2

[0056] The macromolecular emulsifier is polyethylene glycol 600 monomethyl ether, which is heated and melted in the reactor, and methacrylic acid is added in an equimolar ratio. Alcohol ether ester macromonomer, stand and cool for later use; in addition, mix α-methacrylic acid and methyl methacrylate with a mole number of 1 in a ratio of 6:4 to form a mixed monomer, add the mixed monomer to the aqueous solution Potassium persulfate with a molar ratio of 0.05 is used as a thermal decomposition type initiator, and the unsaturated carboxylic acid polyethylene glycol ether ester macromonomer whose molar number is 0.3 of the molar number of the aforementioned mixed monomers is dissolved in water and heated to 65 ℃, add the mixed monomer dropwise at a controlled rate, and finish dropping within 120 minutes, then keep warm for 120 minutes, cool down to below 40°C, add aqueous sodium bicarbonate solution to adjust the pH value to about 7, and obtain polyoxyethylene ether side groups P...

Embodiment 3

[0065]The macromolecular emulsifier is polyethylene glycol 800 monomethyl ether, which is heated and melted in the reactor, and acrylic acid is added in an equimolar ratio, the temperature is controlled at 60°C to 65°C, and the reaction is carried out for 8 hours to obtain unsaturated carboxylic acid polyethylene glycol ether Ester macromers, let stand and cool for later use; in addition, mix α-methacrylic acid with a molar number of 1 and acrylate-β-hydroxyethyl acrylate in a ratio of 6.5:3.5 to form a mixed monomer, and add the mixed monomer into the aqueous solution Ammonium persulfate with a molar ratio of 0.04 is used as a thermal decomposition type initiator, and the unsaturated carboxylic acid polyethylene glycol ether ester macromonomer whose molar number is 0.25 of the molar number of the aforementioned mixed monomers is dissolved in water and heated to 70 ℃, add the mixed monomer dropwise at a controlled rate, and finish dropping within 120 minutes, then keep warm for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com