A kind of alkali-free concrete surface protective agent and preparation method thereof

A technology for concrete surface and protective agent, applied in the field of building materials, can solve the problems affecting the permeability of water-based permeable crystalline waterproofing agent, concrete alkali-aggregate reaction, low solubility of sodium fluoride, etc., so as to improve the resistance to sulfate corrosion. , Improve the effect of carbonization resistance and rebound strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

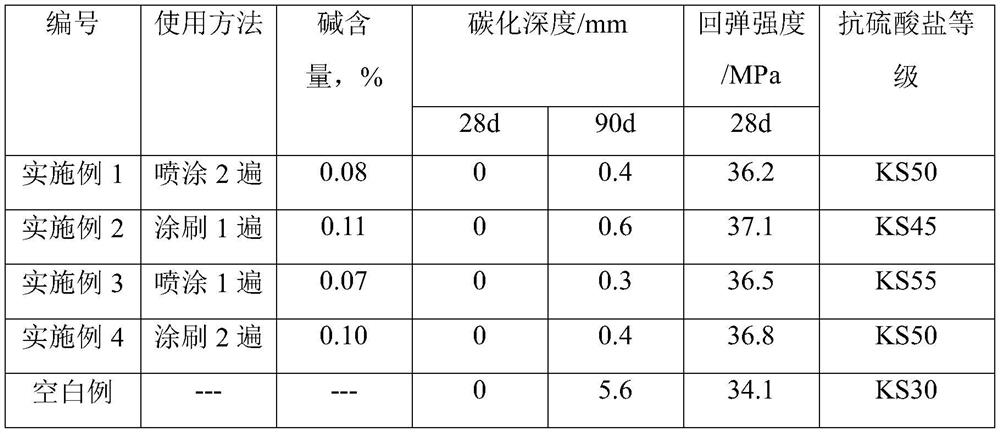

Examples

Embodiment 1

[0033] Preparation of modified fluorosilicic acid: Add 20°Bé fluorosilicic acid into a three-necked flask, control the temperature at 20°C, turn on the stirrer, control the stirring speed at 80r / min, slowly add ethanolamine into the fluorosilicic acid, dropwise time Controlled at 1.5h. After the dropwise addition is completed, the heat preservation reaction is carried out for 0.5 h, and the modified fluorosilicic acid is obtained. The mass ratio of fluosilicic acid to ethanolamine is 1:0.1;

[0034] Preparation of alkali-free concrete surface protective agent: Add 20 parts of modified fluosilicic acid into the container, add 68.5 parts of water and stir, and control the temperature at 20°C. Then add 8 parts of 20°Bé hydrofluoric acid, 2 parts of ethylenediaminetetraacetic acid, and 0.5 parts of composite surfactant in sequence, and stir for 0.5h. Finally, add 1 part of ethylenediamine to adjust the pH value to 2.4, and the obtained colorless and transparent liquid is the con...

Embodiment 2

[0036] Preparation of modified fluorosilicic acid: Add 30°Bé fluorosilicic acid into a three-necked flask, control the temperature at 30°C, turn on the stirrer, control the stirring speed at 60r / min, slowly add triethanolamine into the fluorosilicic acid, dropwise The time is controlled at 1h. After the dropwise addition is completed, keep the reaction for 1 hour to obtain the modified fluorosilicic acid. The mass ratio of fluosilicic acid to alkanolamine is 1:0.3;

[0037] Preparation of alkali-free concrete surface protection agent: Add 30 parts of modified fluosilicic acid into the container, add 57.5 parts of water and stir, and control the temperature at 40 °C. Then add 2 parts of 40°Bé hydrofluoric acid, 4 parts of ethylene glycol diethyl ether diamine tetraacetic acid, and 1.5 parts of composite surfactant in sequence, and stir for 1.5 hours. Finally, add 5 parts of ammonia water to adjust the pH value to 2.0, and the obtained colorless and transparent liquid is the c...

Embodiment 3

[0039] Preparation of modified fluorosilicic acid: Add 25°Bé fluorosilicic acid into a three-necked flask, control the temperature at 35°C, turn on the stirrer, control the stirring speed at 40r / min, slowly add diethanolamine into the fluorosilicic acid, drop The time is controlled at 2h. After the dropwise addition was completed, the heat preservation reaction was carried out for 0.6h, and the modified fluorosilicic acid was obtained. The mass percentage of fluosilicic acid and alkanolamine is 1:0.2;

[0040] Preparation of alkali-free concrete surface protective agent: Add 25 parts of modified fluosilicic acid into the container, add 62.5 parts of water and stir, and control the temperature at 50°C. Then add 4 parts of 20°Bé hydrofluoric acid, 3 parts of cyclohexanetetraacetic acid, and 1.5 parts of composite surfactant in sequence, and stir for 1 hour. Finally, add 4 parts of diethylamine to adjust the pH value to 3.0, and the obtained colorless transparent liquid is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com