Anti-browning processing method of whole sweet potato powder

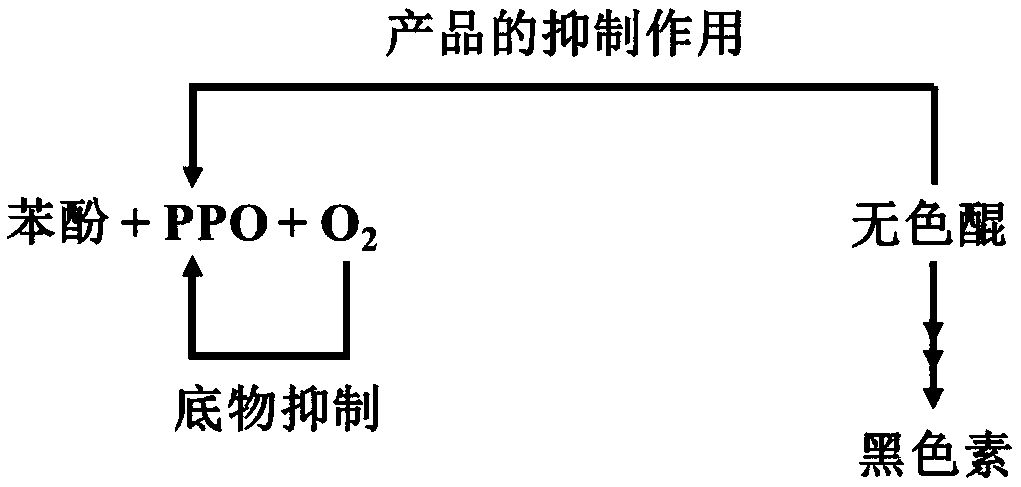

A technology of sweet potato whole powder and processing method, which is applied in metal processing, ultra-high pressure food processing, food mechanical processing, etc., can solve the problems of poor adhesion and dispersion of products, excellent quality, and reduced activity of nutritional components, so as to maintain cell integrity, The effect of keeping nutrients from being lost and inhibiting browning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of anti-browning processing method of whole sweet potato powder, the steps are as follows:

[0034] (1) Ultrasonic pretreatment. Fresh, plump, even-sized mature tubers are removed from the damaged, disabled and diseased tubers, and placed in a sealed refrigerator for pulse-type ultrasonic treatment to keep the gas condition in the box at 100% O 2 , temperature 10°C ± 0.5°C, relative humidity 90% to 95%, ultrasonic pulse treatment for 4 hours, ultrasonic intermittent operation for 10 minutes, stop for 10 minutes, ultrasonic frequency 28kHz.

[0035] (2) Cleaning and peeling: take out the sweet potatoes after ultrasonic treatment, clean and remove the hard parts at both ends, and peel them for later use.

[0036] (3) Water jet slicing: use ultra-high pressure water jet cutting knife to cut sweet potato fruit into 5-10mm thick slices, after cutting, a layer of water film will be formed on the cut surface of the fruit, which plays the role of oxygen barrier and colo...

Embodiment 2

[0042] The difference from Example 1 is that the oxygen in the box of step (1) is 80%.

Embodiment 3

[0044] The difference from Example 1 is that step (1) does not feed oxygen.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com