Lithium borohydride and molybdenum disulfide composite system solid electrolyte material, and preparation method and application thereof

A solid electrolyte, lithium borohydride technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as limited applications, poor safety, and low ion selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] in the isolated air (H 2 O2 4 ball mill, then MoS 2 and ball-milled LiBH 4 According to the set molar ratio (xLiBH 4 -yMoS 2) calculate the mass, put it into a stainless steel spherical tank equipped with stainless steel grinding balls; adopt the mechanical ball milling method of a planetary wheel ball mill, under the protection of high-purity (99.9999%) inert gas (argon), to obtain xLiBH 4 -yMoS 2 composite particles. The total mass of the sample in the spherical tank is 1 g, the volume of the ball mill tank is 100 ml, the weight ratio of the grinding ball to the sample is 40:1, and the revolution speed is set to 450 revolutions per minute. LiBH 4 20 hours for ball milling alone, xLiBH 4 -yMoS 2 The mixture was ball milled for 3 hours. Take out the ball mill to obtain xLiBH 4 -yMoS 2 The mixture is then loaded into the sample cell of the Sievert type gas-solid reaction closed device for high temperature dehydrogenation reaction, the dehydrogenation temperatu...

Embodiment 2

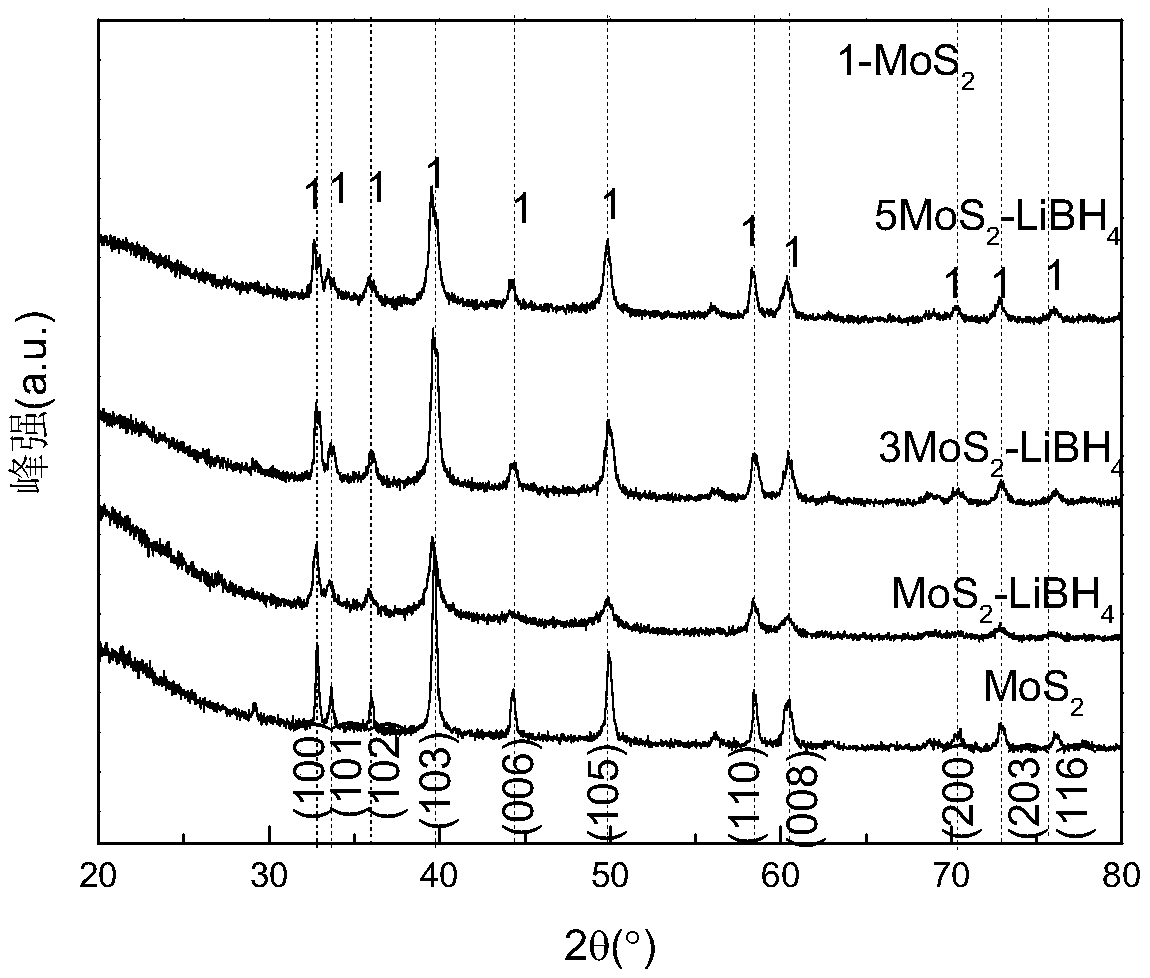

[0033] Take out part of the xLiBH of the samples with different raw material ratios in Example 1 4 -yMoS 2 The composite particles and the material obtained after dehydrogenation were subjected to X-ray diffraction (XRD) experiments. The sample cell was covered with a specific polymer film and sealed with a glass slide with vacuum grease to prevent water and oxygen in the air from affecting the sample. effect. The target material of the X-ray source used is a Cu target, the tube voltage is 40kV, and the tube current is 40mA. The obtained XRD pattern is as figure 1 , shown in 4.

[0034] xLiBH after ball milling 4 -yMoS 2 Only pure 2H-MoS in the complex (x:y=1:1, 1:3, 1:5, 1:7, 3:1, 5:1) 2 Phase, LiBH 4 Has become an amorphous phase, so there is no peak in XRD ( figure 1 ). xLiBH 4 -yMoS 2 After high temperature dehydrogenation of the complex (x:y=1:1, 1:3, 1:5, 3:1, 5:1), a new phase was generated. From the XRD pattern ( Figure 4 ), it can be seen that LiMoS 2 , ...

Embodiment 3

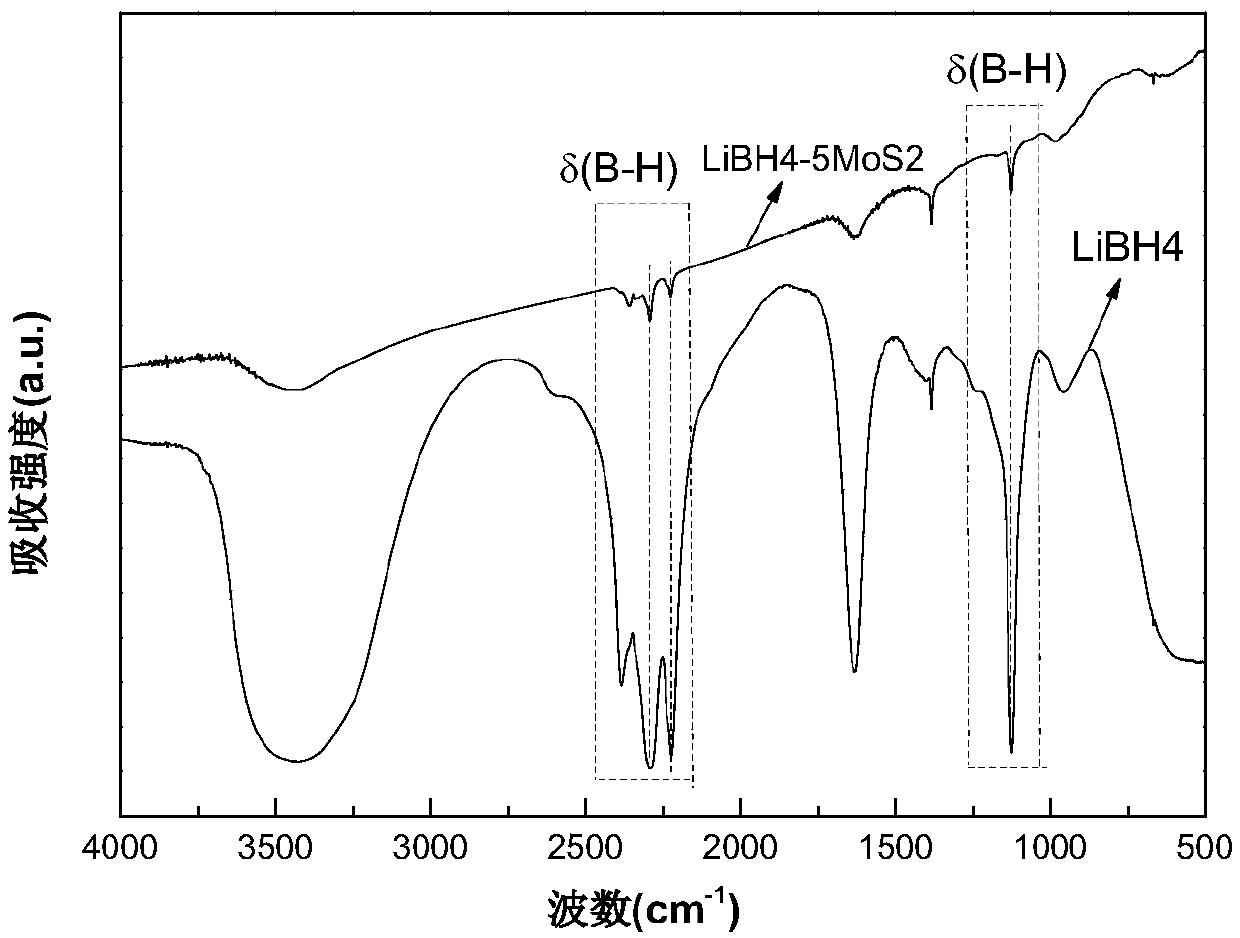

[0050] Take out part of the xLiBH of the samples with different raw material ratios in Example 1 4 -yMoS 2 The composite particles were tested by Fourier transform infrared spectroscopy (FTIR). Since the experimental samples had to be isolated from the air, the whole preparation was carried out in a glove box. According to the mass ratio, sample powder: KBr powder = 1:200, mix the two powders, and grind them evenly. The prepared powder is stored in a small brown glass bottle. Before the FTIR test, the powder sample was taken out of the glass bottle, and an appropriate amount of powder was put into the tableting mold, pressed for 1 minute under the pressure of 12MPa, then released for 30 seconds, and pressed for 1 minute to obtain the tablet test sample. Test results such as figure 2 shown.

[0051] As can be seen from the figure, pure LiBH 4 The two B-H characteristic peaks in the prepared LiBH 4 -5MoS 2 is still present in the complex, as evidenced by LiBH 4 existenc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com