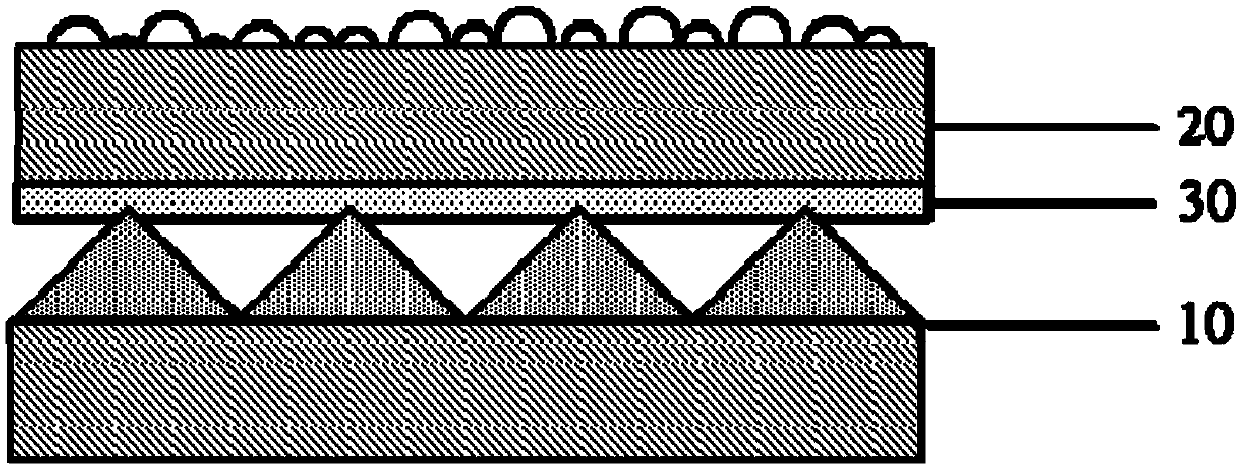

Coating composition for laminating layer of diffusion and brightness enhancement composite film, diffusion and brightness enhancement composite film and preparation method thereof

A technology of coating composition and composite film, which is applied in the direction of coating, optics, optical components, etc., can solve problems such as delamination and crease, and achieve good anti-delamination and bending resistance, good bonding effect, The effect of improving bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] The preparation method of the coating composition provided by the present invention: mix the acrylate oligomer, the urethane acrylate monomer, and the photoinitiator according to the proportion, and then add the diluent to adjust the viscosity to 11-13s, stir evenly, and filter Then is the coating composition that can be coated on the substrate.

[0066] Further, pay attention to shading during the preparation process.

[0067] Further, the viscosity of the coating composition is measured using a Tu-4 cup.

[0068] The coating composition provided by the present invention is used as the application method of the bonding layer of the diffusion and brightness enhancement composite film. A wire bar coater is used to uniformly coat the uniformly mixed coating composition on the blank substrate on the back of the diffusion layer at 100°C. Bake down for 3 minutes, then use the composite roller to compound the lower prism layer, and then perform UV curing under a UV curing lamp. The...

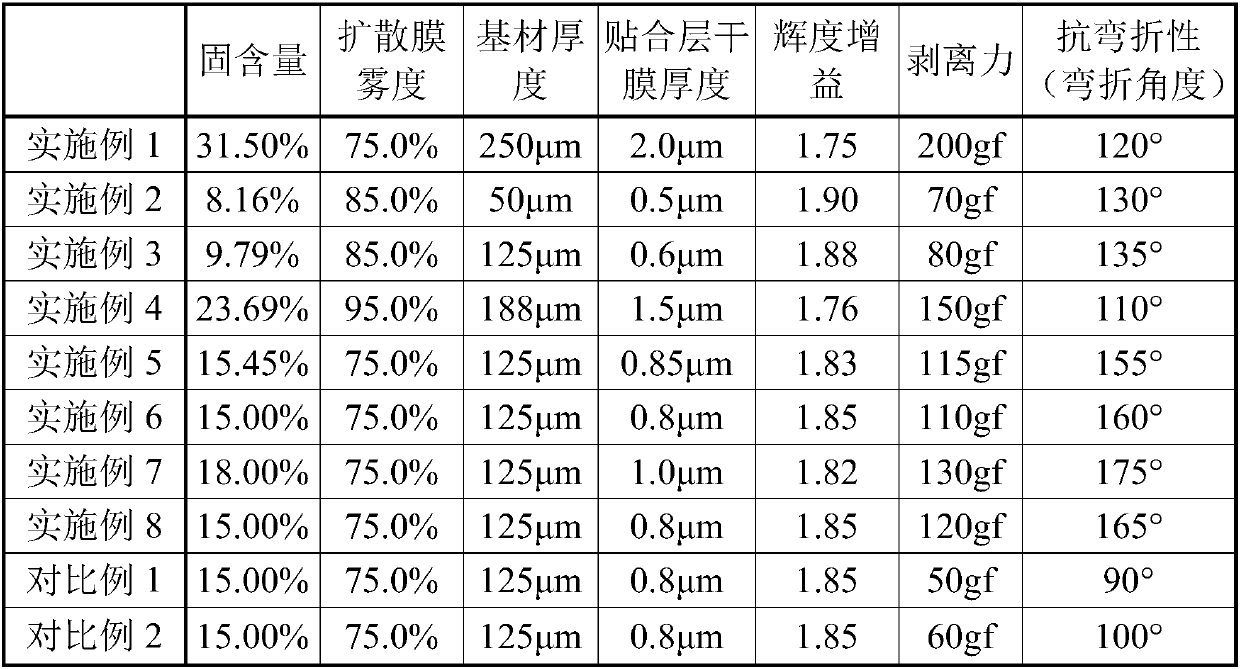

Embodiment 1

[0077] The present invention provides a coating composition for a bonding layer of a diffusing light-enhancing composite film and a diffusing light-enhancing composite film.

[0078] The coating composition includes 20% acrylate oligomer, 10% monomer, 1.5% photoinitiator, and 68.5% diluent. The acrylate oligomer is a tetrafunctional polyester acrylic resin; the monomer is a trifunctional alicyclic urethane acrylic resin, the glass transition temperature is 30°C, and the monomer and the acrylate oligomer are The weight ratio is 0.5:1; the photoinitiator is Irgacure 184, and the weight ratio to acrylic resin is 5:100; the diluent is methyl ethyl ketone. The solid content of the coating composition is 31.5%.

[0079] The diffusion layer includes: polyol copolymer, isocyanate trimer, polymethyl methacrylate particles. The polyol copolymer is polyethylene adipate-propylene glycol ester diol, polyethylene adipate-1,4-butanediol ester diol, and polyneopentyl adipate glycol-1 , 6-hexane...

Embodiment 2

[0083] The coating composition for the bonding layer of the diffusion and brightness enhancement composite film and the diffusion and brightness enhancement composite film provided in Example 1, the coating composition includes: 5% of acrylate oligomer, 3% of monomer, and photoinitiator 0.16%, diluent 91.84%. The acrylate oligomer is a six-member epoxy acrylic resin; the monomer is a six-member aromatic urethane acrylic resin, the glass transition temperature is 60°C, and the monomer is different from the acrylate oligomer. The weight ratio is 0.6:1; the photoinitiator is Irgacure 184, and the weight ratio to the acrylic resin is 2:100; the diluent is ethyl acetate. The solid content of the coating composition is 8.16%.

[0084] The diffusion layer includes: polyol copolymer, isocyanate trimer, polymethyl methacrylate particles. The polyol copolymer is a mixture of polyethylene adipate-propylene glycol ester diol and polyneopentyl adipate-1,6-hexanediol ester diol, and the weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com