Overall bathroom chassis and manufacturing method thereof

A manufacturing method and chassis technology, which can be applied to other household appliances, special buildings, small buildings, etc., can solve the problems of fragility, high production cost, easy edge fracture, etc., achieve low overall cost, solve poor toughness, The effect of simple source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 A manufacturing method of an integral bathroom chassis

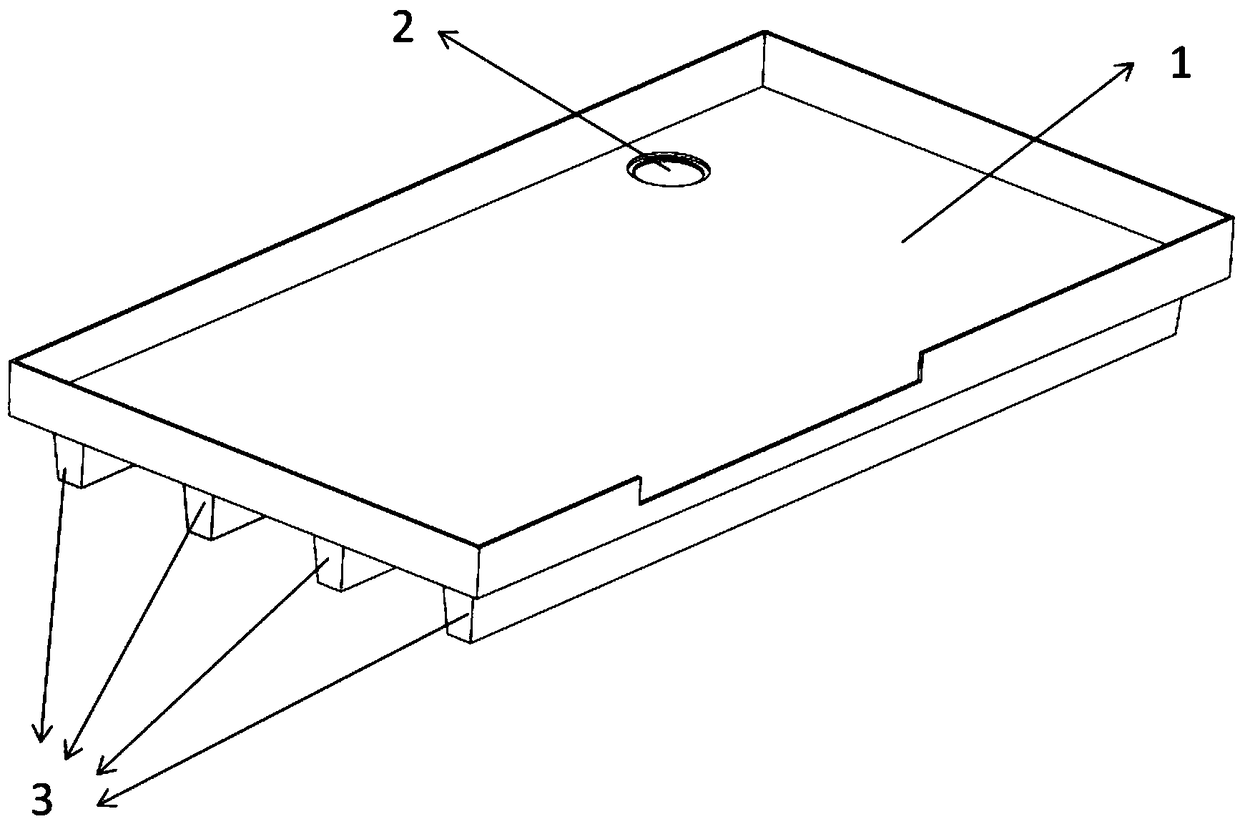

[0039] It includes a chassis main body 1 and a keel 2 arranged under the chassis main body, and a ground drain opening 3 is arranged on the chassis main body.

[0040] Preparation:

[0041] S1. Mix unsaturated polyester resin and 40-mesh quartz sand in a ratio of 1:4, add phenolsulfonic acid, and stir to make a mixed mortar;

[0042] S2, coating a layer of transparent gel coat on the mold surface;

[0043] S3. Casting the mixed mortar into the mould, under a vacuum state;

[0044] S4. Use a plate vibrator to tamp and vibrate the uncured material, place the preformed keel on the mixed mortar to be cured, and apply appropriate pressure to make the mixed mortar and the keel co-glued. The keel material is glass fiber reinforced polyester resin;

[0045] S5. After the material is solidified and formed, demoulding is performed; the semi-finished product after demoulding is subjected to a post-processing...

Embodiment 2

[0047] Embodiment 2 A manufacturing method of an integral bathroom chassis

[0048] The difference between embodiment 2 and embodiment 1 is that step S2 is: apply a layer of transparent gel coat on the surface of the mold, and spread a layer of glass fiber surface mat with marble texture on the transparent gel coat, and the rest are the same as in embodiment 1. .

Embodiment 3

[0049] Embodiment 3 A manufacturing method of an integral bathroom chassis

[0050] It includes a chassis main body and a keel arranged under the chassis main body, and a floor drain is arranged on the chassis main body.

[0051] S1. Mix unsaturated polyester resin and 40-mesh quartz sand at a ratio of 1:3, add phenolsulfonic acid, and stir to make a mixed mortar I; mix unsaturated polyester resin and 4-mesh quartz sand at a ratio of 1:3 Mix in a ratio of 4, add phenolsulfonic acid, and stir to make a mixed mortar II; mix the unsaturated polyester resin and 4-purpose quartz sand in a ratio of 1:4, add phenolsulfonic acid, and stir to make a mixed mortar II. Glue III;

[0052]S2. Apply one deck of gray gel coat on the surface of the mold under vacuum conditions, then spread the first layer of 180 g / square meter glass fiber mat soaked with unsaturated polyester resin on the gray gel coat;

[0053] S3. Keeping the vacuum condition, pour the mixed glue I on the glass fiber mat t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com