A kind of binding agent, polycrystalline cubic boron nitride cutting tool and preparation method thereof

A technology of cubic boron nitride and polycrystalline cubic, which is applied in the direction of lathe cutting tools, turning equipment, manufacturing tools, etc., can solve the problems of poor toughness, decreased wear resistance of polycrystalline cubic boron nitride, etc., and achieve toughness Poor, promote sintering, good toughening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

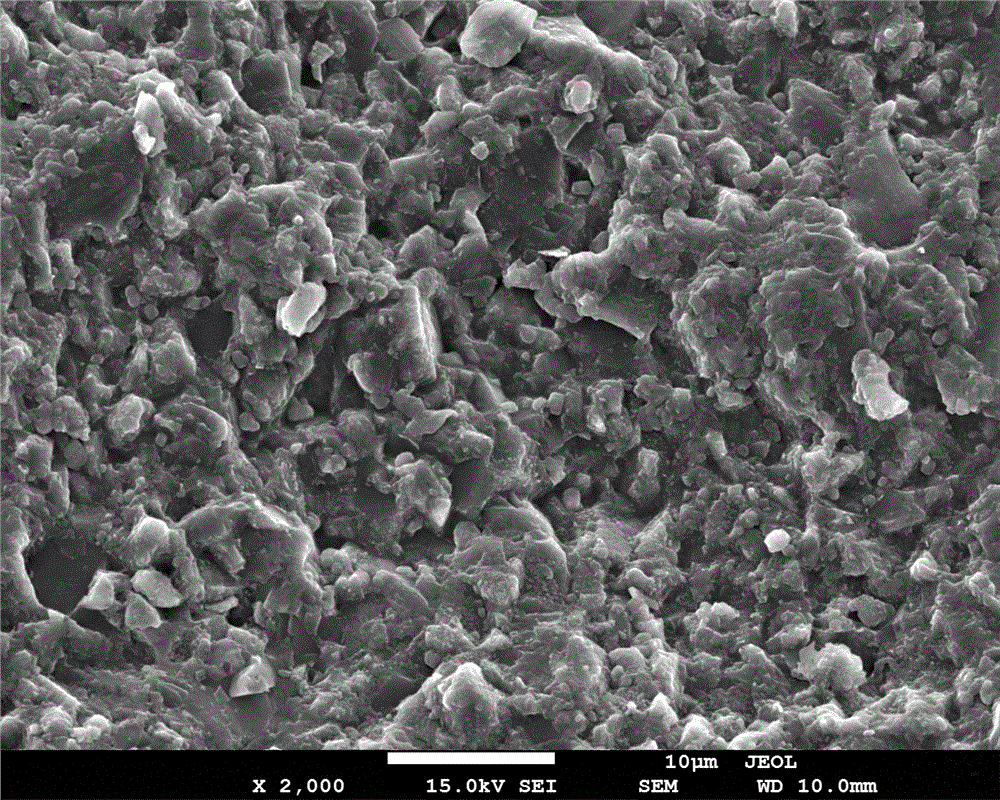

Image

Examples

Embodiment 1

[0014] A kind of binding agent, described binding agent is made up of the raw material of following percentage by weight: B 4 C powder 4%, activated carbon powder 12%, silicon carbide whiskers 60%, and the balance is Al powder. The polycrystalline cubic boron nitride tool prepared by using the binder is composed of the following raw materials in weight percentage: 65% of cubic boron nitride powder and 35% of binder.

[0015] The preparation method of the polycrystalline cubic boron nitride cutting tool includes the following steps: ① Cubic boron nitride powder treatment: pickling cubic boron nitride powder (with a particle size of 1-10 µm) with 15mol / L hydrofluoric acid for 3 hours , centrifuge the acid-washed cubic boron nitride powder, wash it with distilled water for 3 times, wash it with absolute ethanol for 3 times, and then put it in a vacuum drying oven to dry at 60°C for 10 hours; ②After treating the binder with step ① Add the cubic boron nitride powder into the three...

Embodiment 2

[0018] A kind of binding agent, described binding agent is made up of the raw material of following percentage by weight: B 4 C powder 2%, activated carbon powder 20%, silicon carbide whiskers 40%, and the balance is Al powder. The polycrystalline cubic boron nitride tool prepared by using the binder is composed of the following raw materials in weight percentage: 85% of cubic boron nitride powder and 15% of binder.

[0019] The preparation method of the polycrystalline cubic boron nitride cutting tool comprises the following steps: ① Cubic boron nitride powder treatment: the cubic boron nitride powder is pickled with 10mol / L hydrofluoric acid for 4 hours, and the pickled cubic boron nitride is The boron powder was separated by centrifugation, washed twice with distilled water and four times with absolute ethanol, and then dried in a vacuum oven at 40°C for 12 hours; The mixing machine is used for mixing, the total weight of the binder and cubic boron nitride powder and the w...

Embodiment 3

[0022] A kind of binding agent, described binding agent is made up of the raw material of following percentage by weight: B 4 C powder 10%, activated carbon powder 5%, silicon carbide whiskers 50%, and the balance is Al powder. The polycrystalline cubic boron nitride cutting tool prepared by using the bonding agent is composed of the following raw materials in weight percentage: 40% of cubic boron nitride powder and 60% of bonding agent.

[0023] The preparation method of the polycrystalline cubic boron nitride cutting tool comprises the following steps: ① Cubic boron nitride powder treatment: the cubic boron nitride powder is pickled with 20mol / L hydrofluoric acid for 2 hours, and the pickled cubic boron nitride is The boron powder was separated by centrifugation, washed 4 times with distilled water and 2 times with absolute ethanol, and then dried in a vacuum oven at 80°C for 8 hours; Mixing by a mixer, the weight ratio of the total weight of the binder and cubic boron nitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com