Group-III nitride p-type ohmic electrode structure with low contact resistance

A technology of low contact resistance and electrode structure, applied in the direction of circuits, electrical components, laser components, etc., can solve problems such as low solid solubility, limited tunneling effect, and limited concentration, achieve high tunneling probability characteristics, and improve ohm Contact characteristics and the effect of reducing contact resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with accompanying drawing:

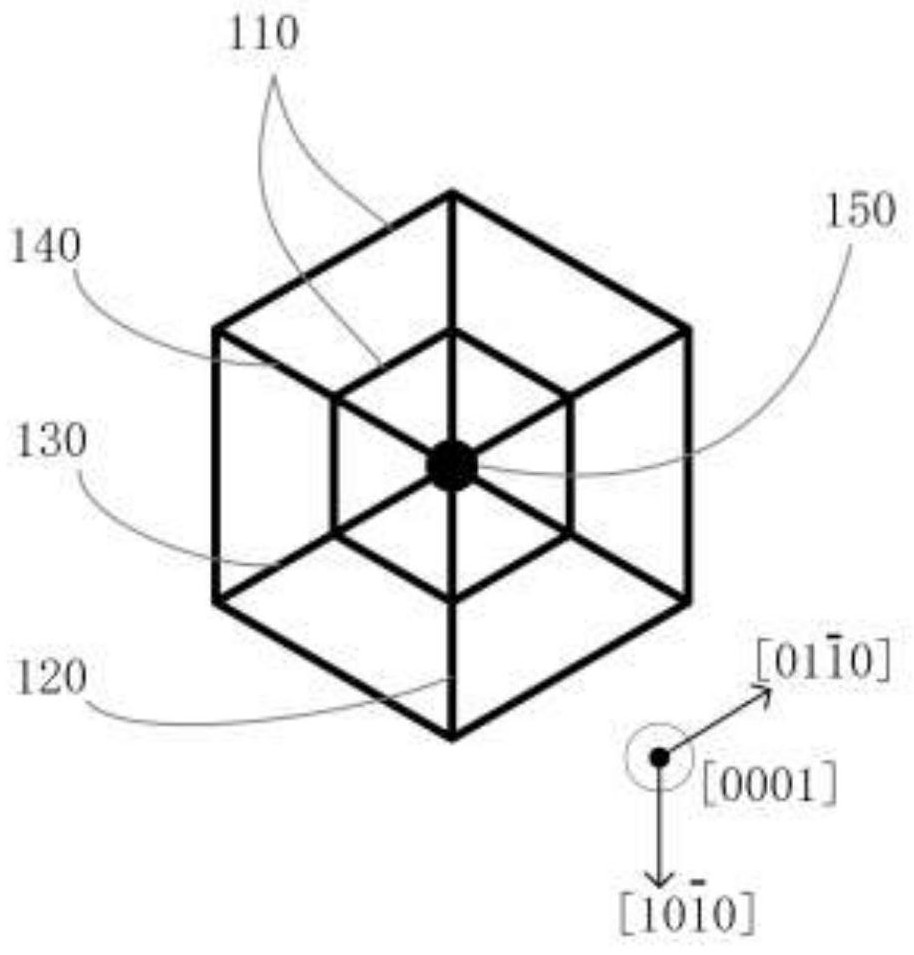

[0023] see figure 1 As shown, as the first embodiment of the present invention, the electrode structure is a regular hexagonal spider web shape, including two concentric regular hexagonal line bodies 110, connecting three pairs of opposite corners of the regular hexagonal line bodies The three positive diagonal lines (120, 130, 140), the welding wire electrode part 150 located at the geometric center of the electrode structure or the intersection of any electrode pattern line body, there are two groups of the three groups of opposite sides of the regular hexagonal line body They are respectively consistent with the first crystal orientation and the second crystal orientation of the III-group nitride, and the remaining group is consistent with the equivalent crystal orientation of the first crystal orientation and the second crystal orientation of the III-group ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com