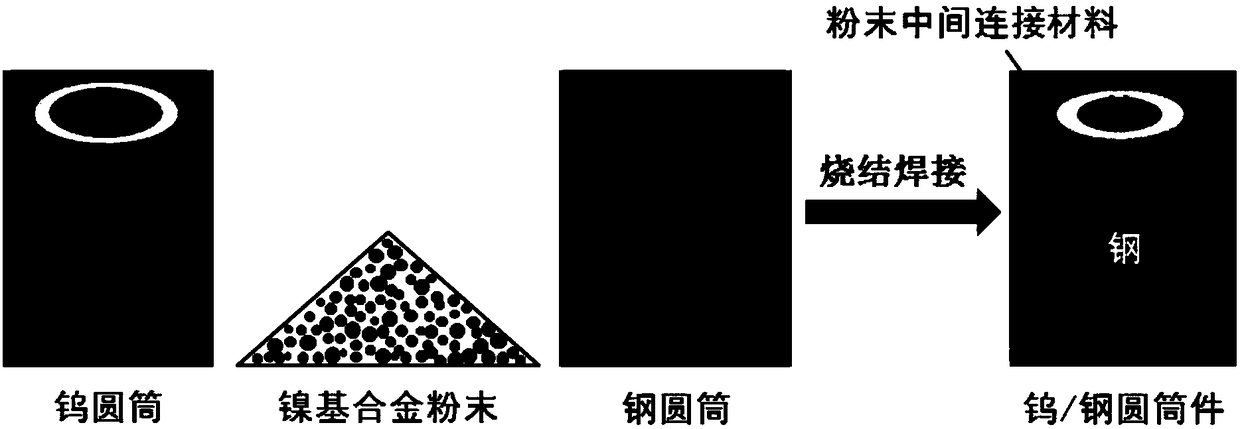

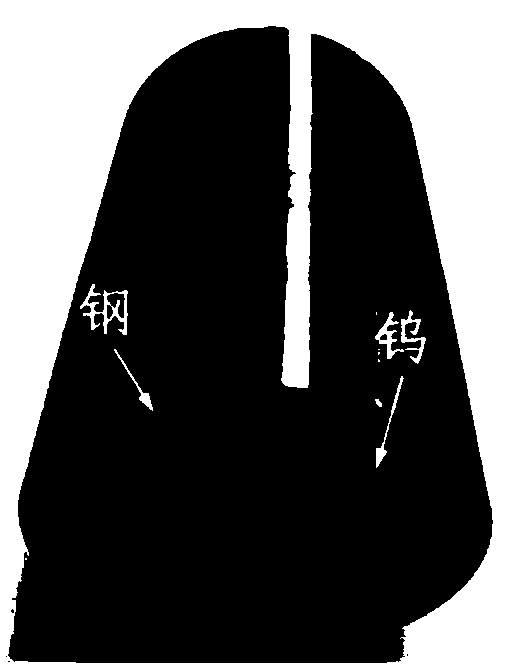

Hot isostatic pressure diffusion bonding method of tungsten/steel cylinder structural part

A technology of hot isostatic pressing diffusion and connection method, which is applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., and can solve the problems of difficult surface treatment of cylindrical structures, large residual stress of welded joints, and easy formation of intermetallic compounds, etc. problems, to achieve the effect of high-performance preparation, high production efficiency and low yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The tungsten cylinder is made of pure tungsten, and the steel cylinder is made of 316L stainless steel. Nickel-based alloy powder is prepared by plasma rotating electrode atomization powder making technology, and the obtained powder is sieved through a 300-mesh screen to obtain a powder intermediate connection material. The powder composition is calculated by mass percentage: 70% nickel, 20% iron, 8% copper , 2% cobalt.

[0055] Put the tungsten cylinder and the steel cylinder on a milling machine for surface processing, so that the surface roughness is 1.6 μm, and then place them in a nitric acid solution with a concentration of 50% for 20 minutes to obtain the tungsten and steel. To be welded.

[0056] Place the parts to be welded of tungsten and steel according to the laminated structure of tungsten lining / steel jacket (the distance between the two is 5 mm), and then lay powder intermediate connecting material between the parts to be welded of tungsten and steel, an...

Embodiment 2

[0061] The tungsten cylinder is made of tungsten-nickel-iron alloy, and its composition is calculated by mass percentage: 93% tungsten, 4.9% nickel, and 2.1% iron. The steel cylinder is made of 30Cr alloy structural steel. Nickel-based alloy powder is prepared by plasma rotating electrode atomization powder making technology, and the obtained powder is sieved through a 500-mesh screen to obtain a powder intermediate connection material. The powder composition is calculated by mass percentage: 70% nickel, 25% iron, 5% cobalt .

[0062] Place the tungsten cylinder and the steel cylinder on a grinding machine for surface processing, so that the surface roughness is 0.8 μm, and then place them in a nitric acid solution with a concentration of 30% for 30 minutes.

[0063] Place the parts to be welded of tungsten and steel according to the stacked structure of tungsten lining / steel jacket (the distance between the two is 2 mm), and then lay powder intermediate connecting material b...

Embodiment 3

[0067] The tungsten cylinder is made of tungsten-nickel-iron alloy, and its composition is calculated by mass percentage: 90% tungsten, 7% nickel, and 3% iron. The steel cylinder is made of 30Cr alloy structural steel. The nickel-based alloy powder is prepared by plasma rotating electrode atomization powder making technology, and the obtained powder is sieved through a 500-mesh screen to obtain the powder intermediate connection material. The powder composition is calculated by mass percentage: 65% nickel, 20% iron, 10% copper , 5% cobalt.

[0068] Place the tungsten cylinder and the steel cylinder on a milling machine for surface processing, so that the surface roughness is 1.6 μm, and then place them in a nitric acid solution with a concentration of 40% for 20 minutes.

[0069] Place the parts to be welded of tungsten and steel according to the laminated structure of tungsten lining / steel jacket (the distance between the two is 5 mm), and then lay powder intermediate connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Interfacial bonding strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com