Activated carbon-loaded type ruthenium catalyst and preparation and application thereof

A ruthenium catalyst and activated carbon technology, applied in the field of activated carbon supported ruthenium catalysts, can solve the problems of poor catalyst selectivity and versatility, low yield of catalytic series of sugar alcohols, unsatisfactory catalyst selectivity, etc. Conversion and product selectivity, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Preparation of Ru / C catalyst

[0025] (1) Pretreatment of activated carbon: Add 20 g of activated carbon to a round bottom ground flask, and then add 300 mL of 10% nitric acid solution. Place the flask in a water bath thermostat, install a reflux condenser on it, turn on the power, set the water bath thermostat to 90°C, and reflux at constant temperature for 3 hours. After the constant temperature is over, it is naturally cooled to room temperature and then filtered, then washed with distilled water until the filtrate is neutral, and dried under vacuum at 60°C.

[0026] (2) Load: add 1.0g of activated carbon treated with nitric acid to 100mL of ultrapure water, add 0.14g of ruthenium trichloride, add 20mL of ethylene glycol, heat up to 80°C, stir and reflux for 12h. After the precipitation is complete, the solution is filtered hot, and the catalyst is washed with distilled water to neutrality. Dry under vacuum at 60°C to prepare a catalytically active Ru / C catal...

Embodiment 2

[0027] Example 2: Sugar conversion rate and selective detection method of sugar alcohol

[0028] Take 20μL of the reactant before sealing the reactor and the product after hydrogenation, and dilute it to 1mL with ultrapure water. Detect the concentration of sugar in the reactant, the residual sugar concentration and sugar alcohol concentration in the product by high performance liquid chromatography .

[0029] The high performance liquid chromatographic instrument used for detection is the 2414 differential detector of waters system, the chromatographic column is AminexHPX-87H column (300×7.8mm), the mobile phase is 5mM H 2 SO 4 , The flow rate is 0.6mL / min, the column temperature is 60.0℃, and the injection volume is 20μL.

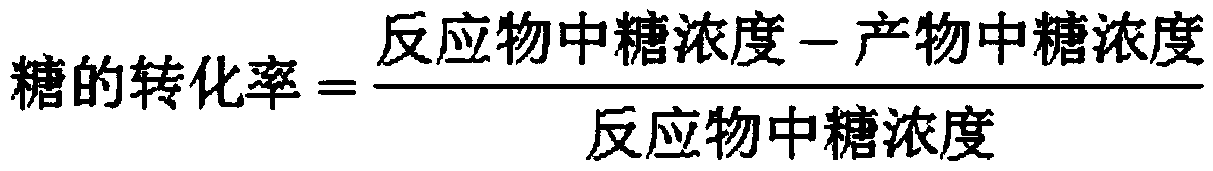

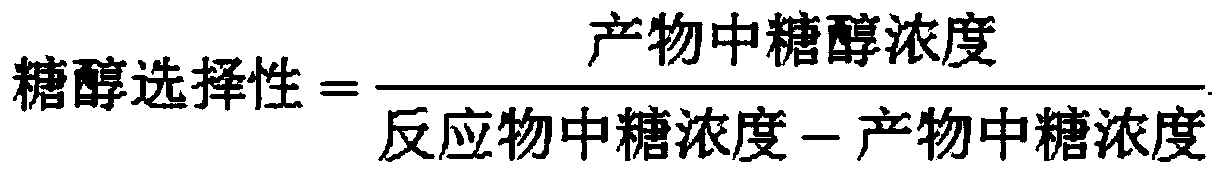

[0030] The formula for calculating sugar conversion rate and sugar alcohol selectivity is as follows:

[0031]

[0032]

Embodiment 3

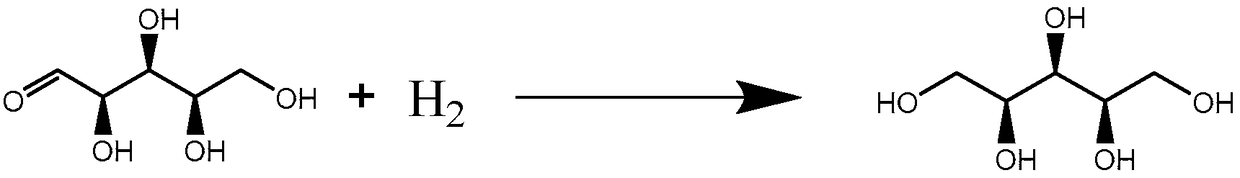

[0033] Example 3: Hydrogenation of xylose to produce xylitol

[0034]

[0035] Weigh 5.0 g of anhydrous xylose, add it to 45 mL of ultrapure water, prepare a 10% xylose solution, transfer the xylose solution to a 100 mL reactor, add 0.5 g of Ru / C catalyst, and seal the reactor. Replace the reactor with nitrogen three times to remove the air in the reactor. Adjust the temperature of the reaction kettle to 120°C and the stirring speed to 500 rpm. After the temperature stabilizes, hydrogen is charged to 4.0 MPa to start the reaction. After 120 minutes of reaction, the reactor was rapidly cooled, and when the temperature dropped to room temperature, hydrogen was vented to end the hydrogenation reaction.

[0036] Using the method of Example 2 for detection, the conversion rate of xylose was 99.2%, and the selectivity of xylitol was 99.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com