Composite negative electrode for thermal battery and preparation method thereof

A thermal battery and negative electrode technology, applied to battery electrodes, primary battery electrodes, circuits, etc., can solve the problems of unable to quickly establish a stable platform voltage, poor discharge rate characteristics, large interface resistance, etc., to achieve great application value and economy Significance, reducing polarization internal resistance, and improving the effect of power output capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

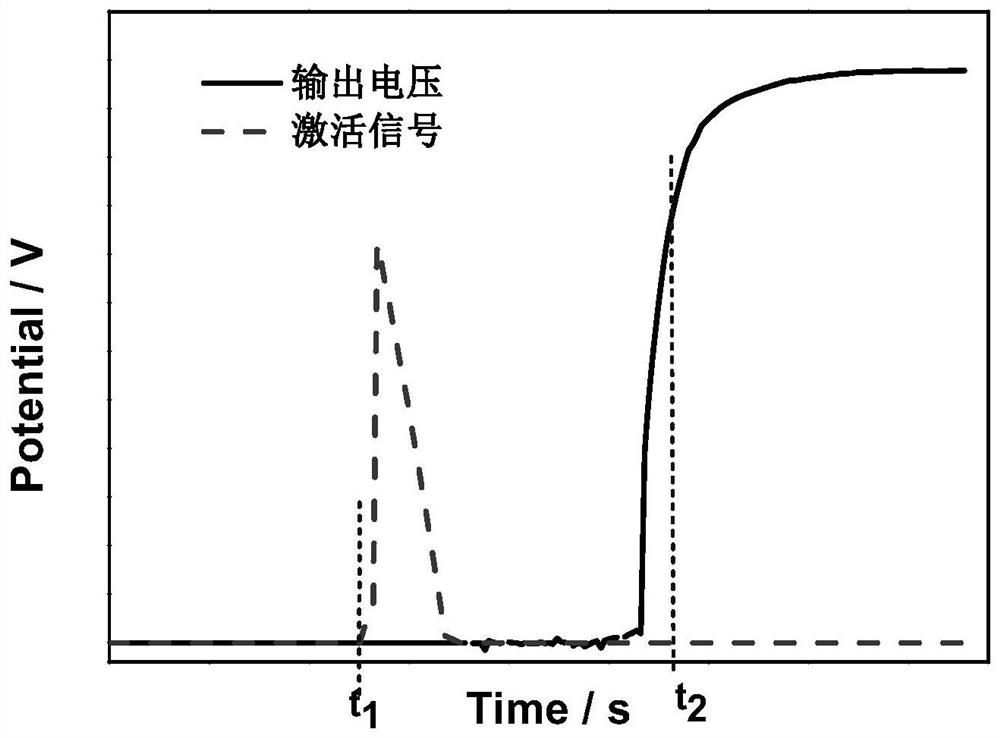

[0027] Here, aiming at the problem of slow voltage build-up and “voltage pits” caused by insufficient ion activity at the initial stage of activation when LiB alloy is used as the negative electrode material for thermal batteries, the present invention provides a composite negative electrode for thermal batteries and a preparation method thereof. LiSi Compatible with LiB, and modify the thin electrolyte coating layer on the surface of the composite negative electrode, so that the composite negative electrode can quickly enter the activation state after receiving the activation signal, improve the activation speed of LiB system thermal battery, and reduce the polarization internal resistance. The composite negative pole of the present invention is especially suitable for power type fast activation heat battery.

[0028] In an embodiment of the composite negative electrode for thermal battery of the present invention, the weight of the LiSi alloy powder layer is 10%-25% of the sh...

Embodiment 1

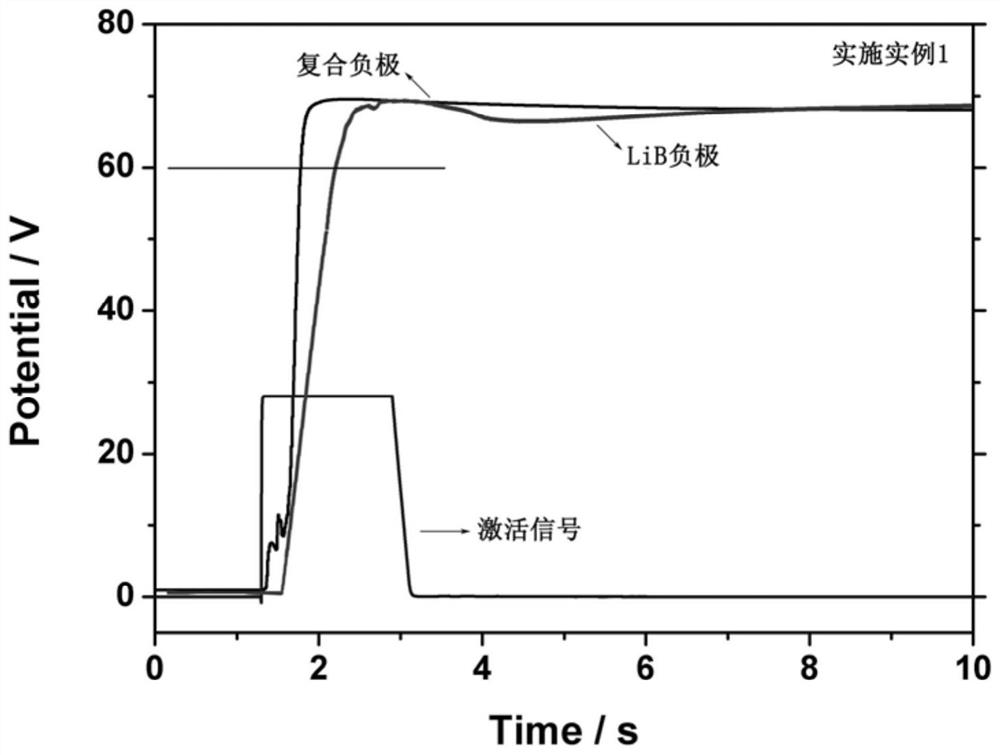

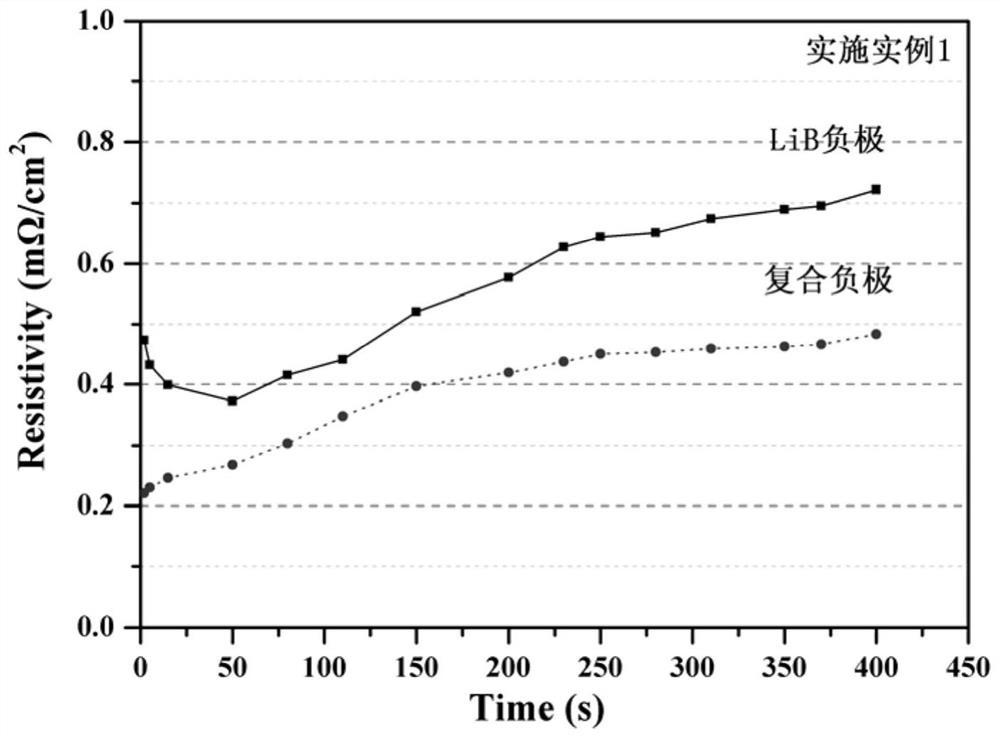

[0044]A composite negative electrode for thermal batteries, the mass percent of its composition is: LiSi alloy powder weight is 20% of LiB alloy; Then, under the protection of argon atmosphere, place 0.15g of all-lithium molten salt electrolyte in the heating tank at the upper end of the quartz drainage tube, heat at 450°C for 10min, and the molten electrolyte diffuses on the composite negative electrode sheet (LiSi side) surface, it can be solidified and formed after standing at room temperature for a while. The LiB negative thermal battery that adopts routine assembly, activation time is 0.89s, and internal resistance is 0.72mΩ / cm Compared with the conventionally assembled LiB negative electrode battery, the activation time is shortened by 47.2%, and the internal resistance is reduced by 33.4% (the battery activation is shown in figure 2 , see the change of internal resistance image 3 ).

Embodiment 2

[0046] A composite negative electrode for thermal batteries, the mass percent of its composition is: LiSi alloy powder weight is 15% of LiB alloy; Then, under the protection of argon atmosphere, place 0.1g of all-lithium molten salt electrolyte in the heating tank at the upper end of the quartz drainage tube, heat at 450°C for 5min, and the molten electrolyte diffuses on the composite negative electrode sheet (LiSi side) surface, it can be solidified and formed after standing at room temperature for a while. The thermal battery assembled using the composite negative electrode sheet described in Example 1 has an activation time of 0.51s and an internal resistance of 0.5mΩ / cm2. Compared with the conventionally assembled LiB negative electrode battery, the activation time is shortened by 42.7%, and the internal resistance is reduced by 30.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com