PCB (Printed Circuit Board) temporary storage conveyor

A technology of conveyor and temporary storage mechanism, applied in the direction of conveyor, mechanical conveyor, conveyor objects, etc., can solve the problem of occupying the installation space of the transport platform, and achieve the effect of rapid and stable entry or delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

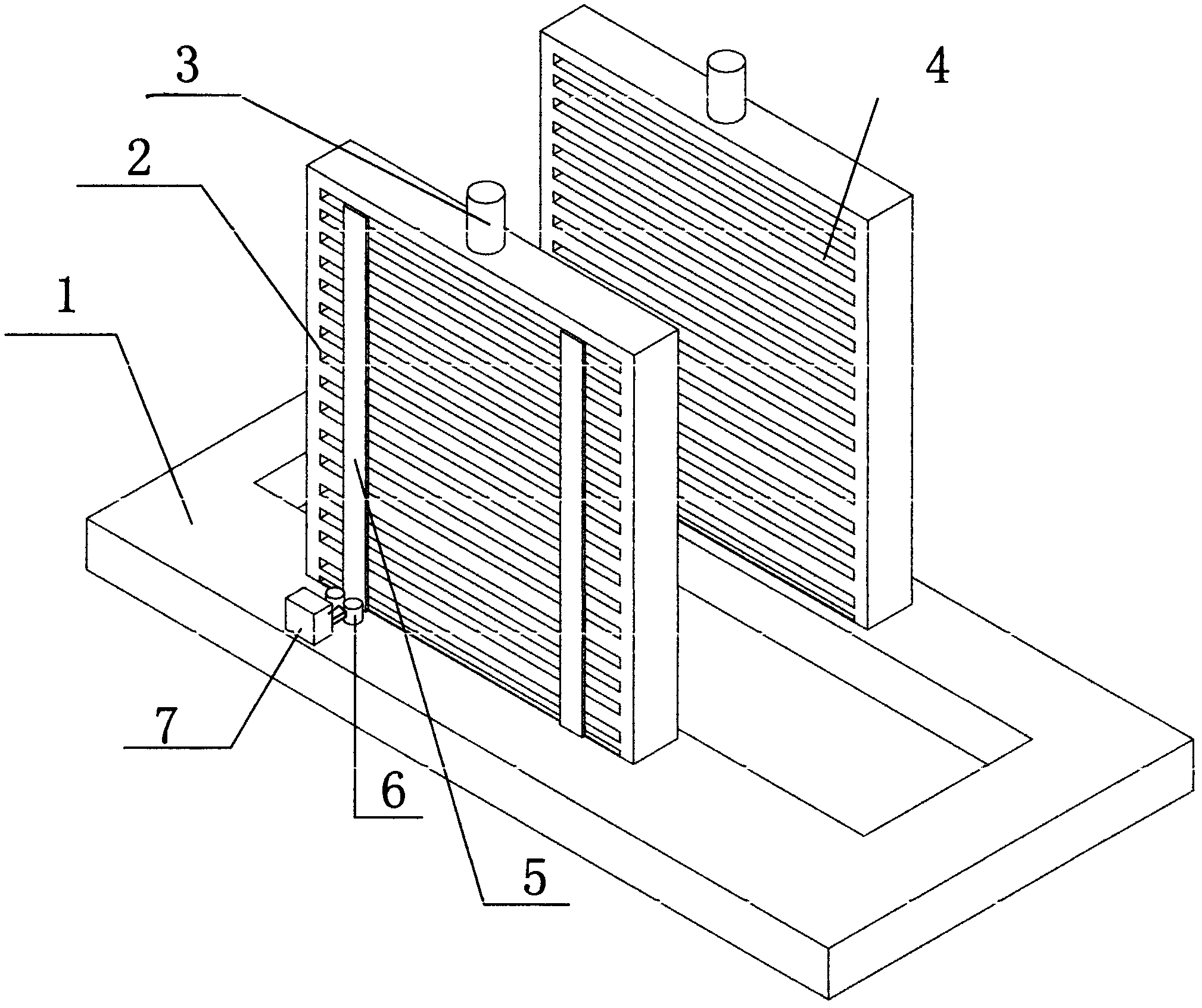

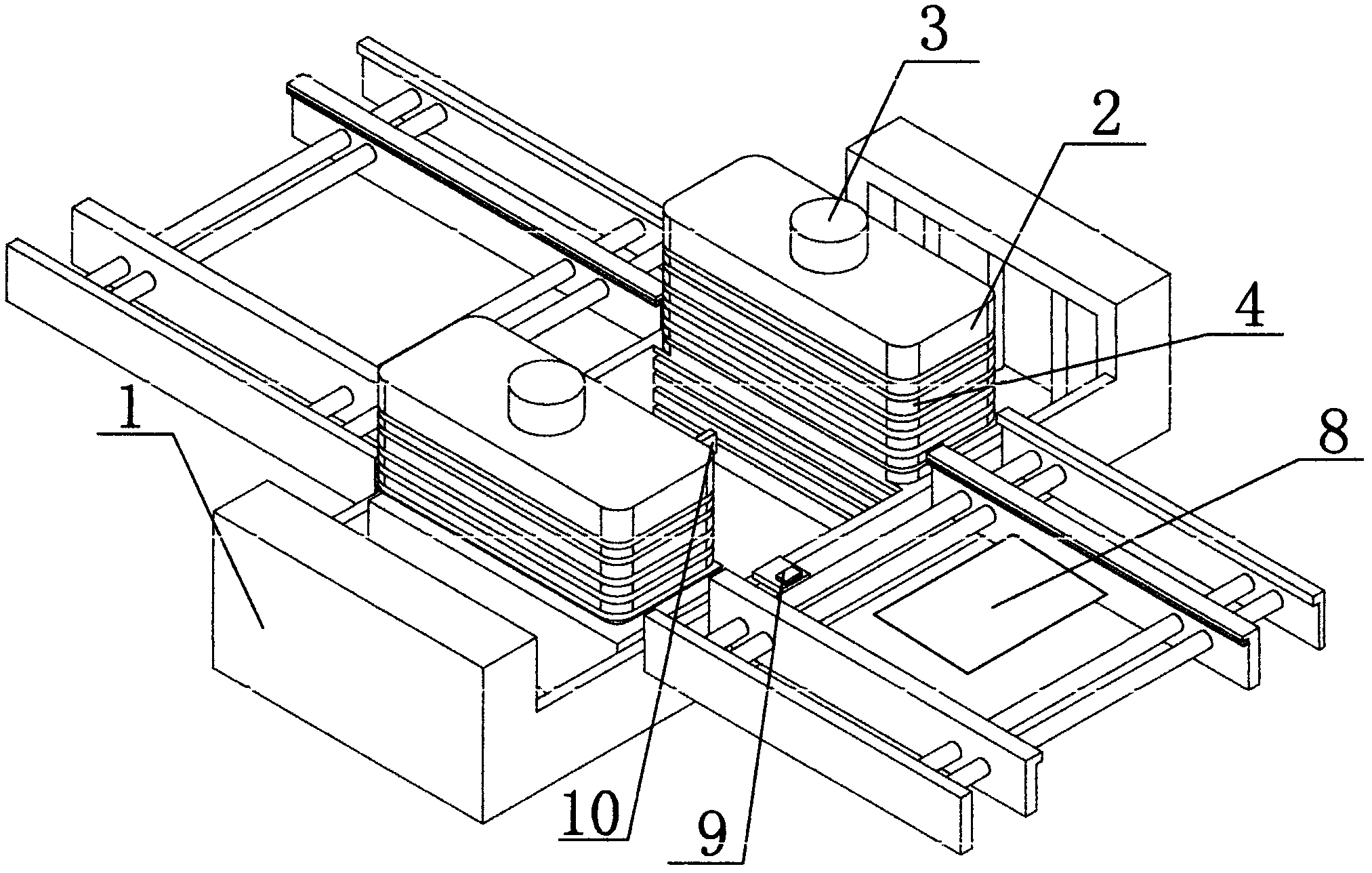

[0013] Such as figure 1 A PCB temporary storage conveyor shown includes a workbench 1 and supports 2 arranged on both sides of the workbench 1, a motor 3 is provided on the upper part of the support 2, and two vertical rollers 5 are arranged on the support 2, At least one row of temporary storage mechanism 4 is provided in the support 2, and a cylinder 7 is provided on one side of the support 2, and the front part of the cylinder 7 is clutched and connected with two transmission wheels 6, and the transmission wheels 6 are connected with the drum. 5 sense connections.

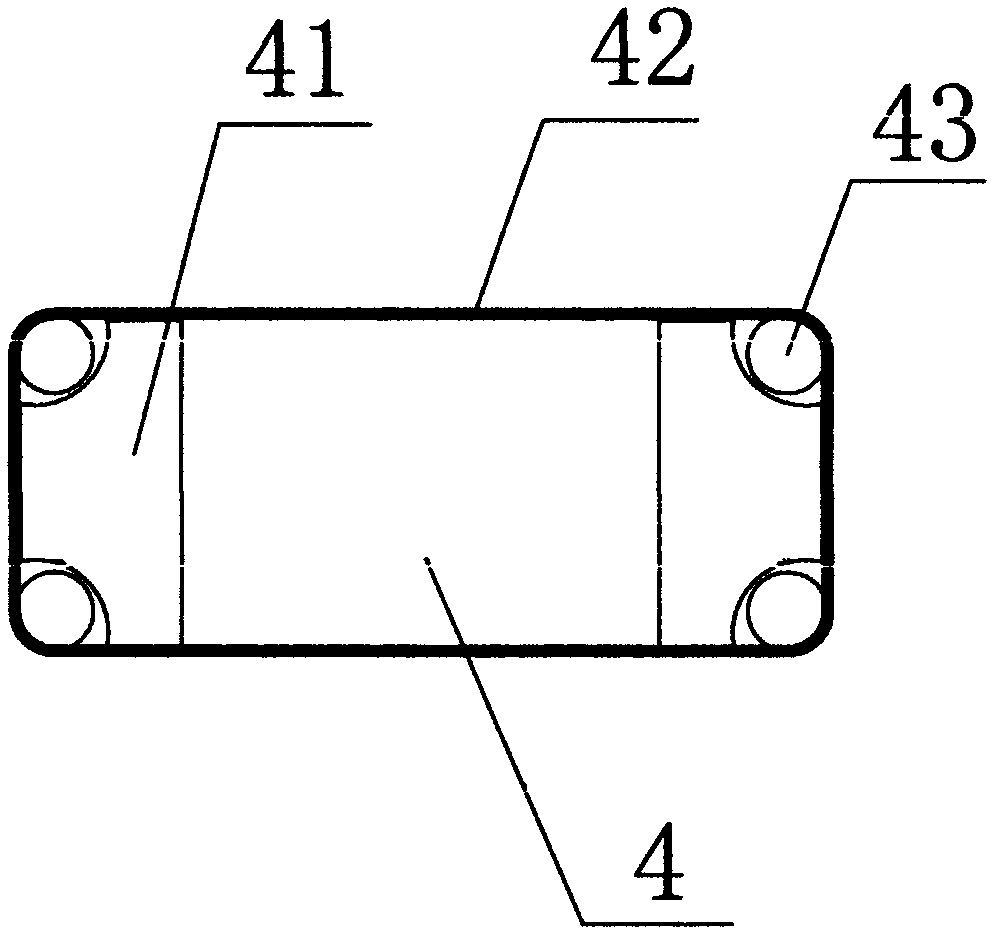

[0014] Further, such as figure 2 The temporary storage mechanism 4 shown includes a temporary storage rack 41, a runner 43 and a belt 42, four corners of the temporary storage rack 41 are provided with runners 43 placed horizontally, and the four runners 43 are sleeved Belt 42 is arranged, and the running wheel 43 that adopts horizontal placement reduces the occupied space.

[0015] Furthermore, in order to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com