Method of preparing conductive anti-corrosion copper coating on aluminum alloy

A conductive anti-corrosion, aluminum alloy technology, applied in the field of preparing conductive anti-corrosion copper coating on aluminum alloy, can solve the problems of easy infiltration, corrosion at the interface, unfavorable for large-scale application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

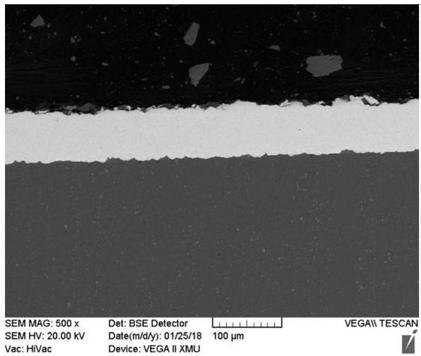

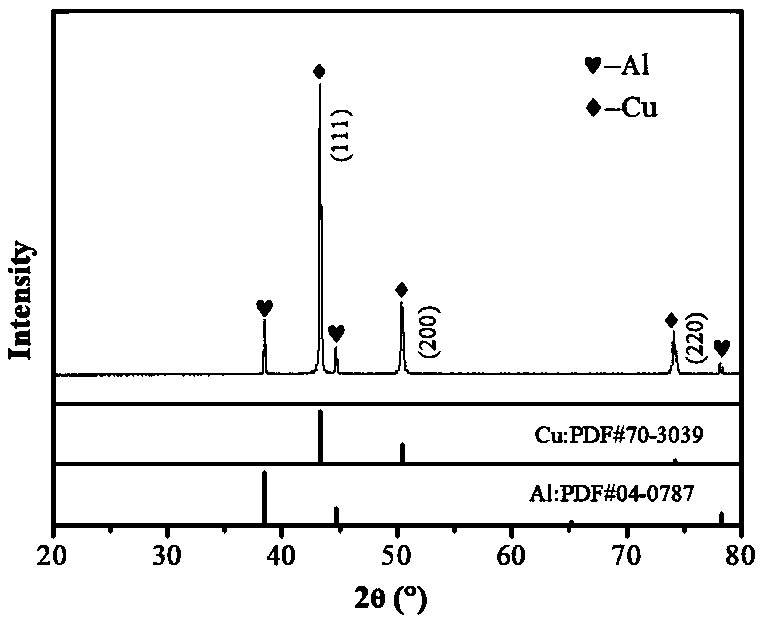

[0047] This embodiment prepares a coating that avoids galvanic corrosion of the aluminum-copper connector, and the specific preparation method includes the following steps:

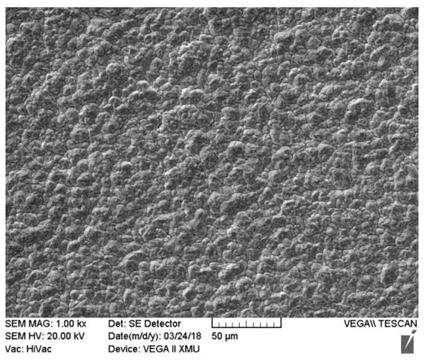

[0048] Step 1, pre-grinding the aluminum alloy sample: use 70 # ~1500 # Sandpaper step by step to 1500 # Then mechanically polish with 1.5 μm and 0.5 μm diamond grinding paste in turn; at room temperature, put the sample in an ultrasonic cleaner and clean it with deionized water for 10 minutes. The average roughness Ra of the sample surface measured by a surface roughness measuring instrument was 0.0371 μm.

[0049] Step 2, chemical degreasing: chemical solution composition and concentration are as follows: sodium hydroxide 10g / L, sodium carbonate 20g / L, trisodium phosphate 20g / L, OP-10 emulsifier 1g / L; soak the sample at 55°C Degreasing in chemical solution for 3 minutes; after degreasing, rinse the sample in warm water at 40°C and then quickly put it into running water for repeated washing.

[0050]...

Embodiment 2

[0059] This embodiment prepares a coating that avoids galvanic corrosion of the aluminum-copper connector, and the specific preparation method includes the following steps:

[0060] Step 1, pre-grinding the aluminum alloy sample: use 70 # ~600 # Sandpaper step by step to 600 # , at room temperature, put the sample in an ultrasonic cleaner and wash it with deionized water for 10 min. The average roughness Ra of the sample surface measured by a surface roughness measuring instrument was 0.1404 μm.

[0061] Step 2, chemical degreasing: chemical solution components and concentrations are as follows: sodium hydroxide 15g / L, sodium carbonate 25g / L, trisodium phosphate 25g / L, OP-10 emulsifier 1g / L; Soak in water for 2 minutes to degrease; after degreasing, rinse the sample in warm water at 40°C and then quickly put it into running water for repeated rinse.

[0062] Step 3, alkali washing: the composition and concentration of the alkaline solution are as follows: sodium hydroxide ...

Embodiment 3

[0069] This embodiment prepares a coating that avoids galvanic corrosion of the aluminum-copper connector, and the specific preparation method includes the following steps:

[0070] Step 1, pre-grinding the aluminum alloy sample: use 70 # ~1500 # Sandpaper step by step to 1500 # ; At room temperature, put the sample in an ultrasonic cleaner and wash it with deionized water for 10 minutes. The average roughness Ra of the sample surface measured by a surface roughness measuring instrument was 0.0732 μm.

[0071] Step 2, chemical degreasing: the composition and concentration of the chemical solution are as follows: sodium hydroxide 20g / L, sodium carbonate 30g / L, trisodium phosphate 30g / L, OP-10 emulsifier 1g / L; Soak in water for 1.5min to degrease; after degreasing, rinse the sample in warm water at 40°C, then quickly put it into running water and rinse repeatedly.

[0072]Step 3, alkali washing: the composition and concentration of the alkaline solution are as follows: sodiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average roughness | aaaaa | aaaaa |

| Corrosion potential | aaaaa | aaaaa |

| Corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com