Scratch-resistant UV metal gloss coating for electrical appliances and usage method thereof

A metallic luster and scratch-resistant technology, applied in polyurea/polyurethane coatings, coatings, and devices for coating liquids on surfaces, can solve problems such as electrical wear, scratches, and poor adhesion of pigments and metal powders. Achieve the effects of improved adhesion, excellent wear and scratch resistance, and simple curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The raw materials of scratch-resistant UV metallic luster paint are: urethane acrylate 29kg, carboxyl acrylate 13kg, epoxy acrylate 16kg, phosphate resin 4kg, sericite 1.5kg, barium sulfate 2.4kg, aluminum powder 2kg, acetylene carbon black 2.6 kg, graphene 0.8kg, perhydropolysilazane 3kg, polydimethylsiloxane 1.6kg, 1-hydroxy-cyclohexyl-phenyl ketone 4kg;

[0028] Add polyurethane acrylate, carboxyl acrylate, epoxy acrylate and phosphate resin into water according to the corresponding weight ratio, put it on an electric mixer and stir at low speed for 10~15min, then mix sericite, barium sulfate, metal powder, acetylene carbon Add black, graphene and perhydropolysilazane to it by weight, and stir at high speed for 10-20 minutes; after high-speed stirring, add leveling agent and photoinitiator, and disperse at high speed for about 20-30 minutes to obtain slurry, adjust viscosity and pH value, both to obtain the required scratch-resistant UV metallic luster coating for el...

Embodiment 2

[0037] The raw materials of scratch-resistant UV metallic gloss paint are: 25kg polyurethane acrylate, 10kg carboxyl acrylate, 10kg epoxy acrylate, 3kg phosphate resin, 1kg sericite, 2kg barium sulfate, 1kg copper powder, 2kg acetylene carbon black, graphite ene 0.5kg, perhydropolysilazane 1kg, polymethylphenylsiloxane 1kg, 2,4,6-trimethylbenzoyldiphenylphosphine oxide 3kg;

[0038] Add polyurethane acrylate, carboxyl acrylate, epoxy acrylate and phosphate resin into water according to the corresponding weight ratio, put it on an electric mixer and stir at low speed for 10~15min, then mix sericite, barium sulfate, metal powder, acetylene carbon Add black, graphene and perhydropolysilazane to it by weight, and stir at high speed for 10-20 minutes; after high-speed stirring, add leveling agent and photoinitiator, and disperse at high speed for about 20-30 minutes to obtain slurry, adjust viscosity and pH value, both to obtain the required scratch-resistant UV metallic luster coa...

Embodiment 3

[0042] The raw materials of scratch-resistant UV metallic luster paint are: 35kg polyurethane acrylate, 15kg carboxyl acrylate, 20kg epoxy acrylate, 5kg phosphate resin, 2kg sericite, 3kg barium sulfate, 3kg tin powder, 3kg acetylene carbon black, graphite ene 1kg, perhydropolysilazane 5kg, isophorone 2kg, 2-hydroxy-2-methyl-1-phenyl-1-acetone 5kg;

[0043] The method of use is as follows: First, fully stir the scratch-resistant UV metallic luster paint evenly, then spray it on the surface of plastic electrical appliances, and at the same time use ultraviolet light irradiation, the intensity of ultraviolet light irradiation is 300μW / m 2 , the power is 220W, the irradiation time is 20min, and it is cured for 1h in an ammonia atmosphere at a temperature of 90°C to obtain a dense black and bright metallic luster coating.

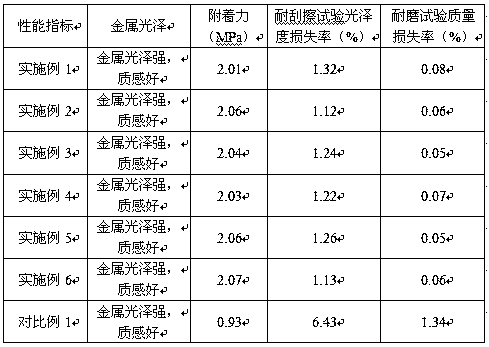

[0044] The test method is consistent with Example 1, and the obtained data are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com