Preparation method of high-thermal-conductivity copper for chemical plating on silicon nitride ceramic surface

A technology of silicon nitride ceramics and surface chemistry, applied in the field of ceramic materials, can solve the problems of prone to cracks, mismatching mechanical properties, chipping materials, etc., to improve strength and impact resistance, precise and controllable details, and three waste discharge. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A preparation method for electroless copper plating on the surface of high thermal conductivity silicon nitride ceramics, the specific steps are as follows:

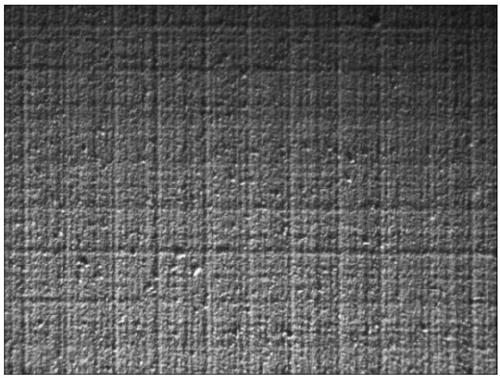

[0039] The silicon nitride ceramic substrate is sequentially processed by tape casting, laser scanning treatment on the surface of the green body, cold water washing, surface protection treatment, pressureless sintering, running water cleaning, degreasing, hot water washing, cold water washing, distilled water washing, chemical copper plating treatment, protection Atmosphere roasting treatment, electroplating copper treatment and anti-oxidation treatment to form a copper film on the surface, of which:

[0040] (1) The main process of tape casting is as follows:

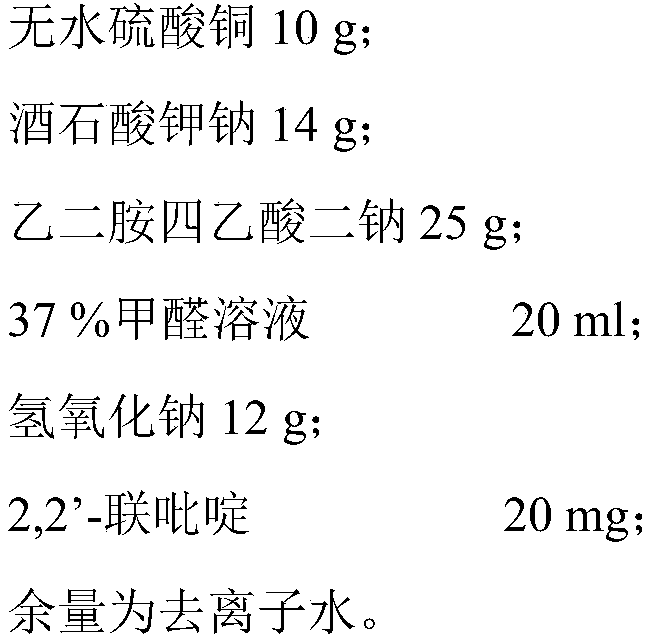

[0041] Weigh 30 g of Si 3 N 4 Fine powder and sintering aid powder (sintering aid accounts for Si 3 N 4 Fine powder weight percentage 10wt%), add 40 grams of organic solvents (dehydrated alcohol and ethyl ketone mix according to 1:2 weight ratio) and ...

Embodiment 2

[0059] A preparation method for electroless copper plating on the surface of high thermal conductivity silicon nitride ceramics. The specific steps are as follows:

[0060] The silicon nitride ceramic substrate undergoes dry pressing molding, surface laser scanning treatment, cold water washing, surface protection treatment, pressureless sintering, running water washing, degreasing, hot water washing, cold water washing, distilled water washing, electroless copper plating treatment, protective atmosphere roasting treatment, electroplating copper treatment and anti-oxidation treatment to form a copper film on the surface, of which:

[0061] (1) The main process of dry pressing is as follows:

[0062] The raw material used is Si 3 N 4 Fine powder, sintering aids are alumina and yttrium oxide powder (weight ratio alumina: yttrium oxide = 1:3), sintering aids are added according to the ratio of 10wt% of raw material weight, and the powder is ball-milled on a planetary ball mill ...

Embodiment 3

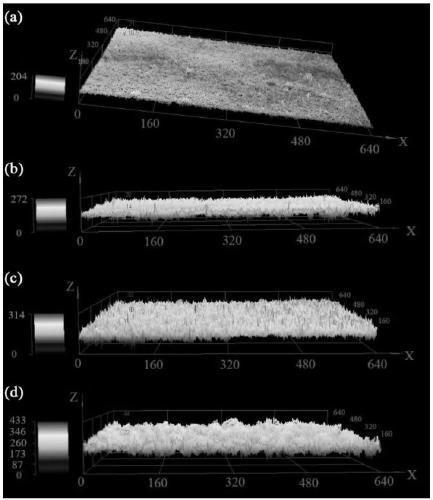

[0079] Embodiment 3: A tape-cast silicon nitride green body is selected, the laser scanning power is selected to be 15% (ie 3W), the scanning distance is 0.05mm, the protective atmosphere is nitrogen, the roasting temperature is 350°C, and the rest of the steps are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com