Preparation method of medical porous titanium or titanium alloy materials coated with tantalum coating on surfaces

A surface coating, titanium alloy technology, applied in coatings, pharmaceutical formulations, metal processing equipment and other directions, can solve the problems of poor bonding force between tantalum coating and substrate, high cost of preparation method, complicated process, etc., to solve the problem of tantalum coating Poor bonding force between layer and substrate, improving metallurgical bonding force and overcoming the effect of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

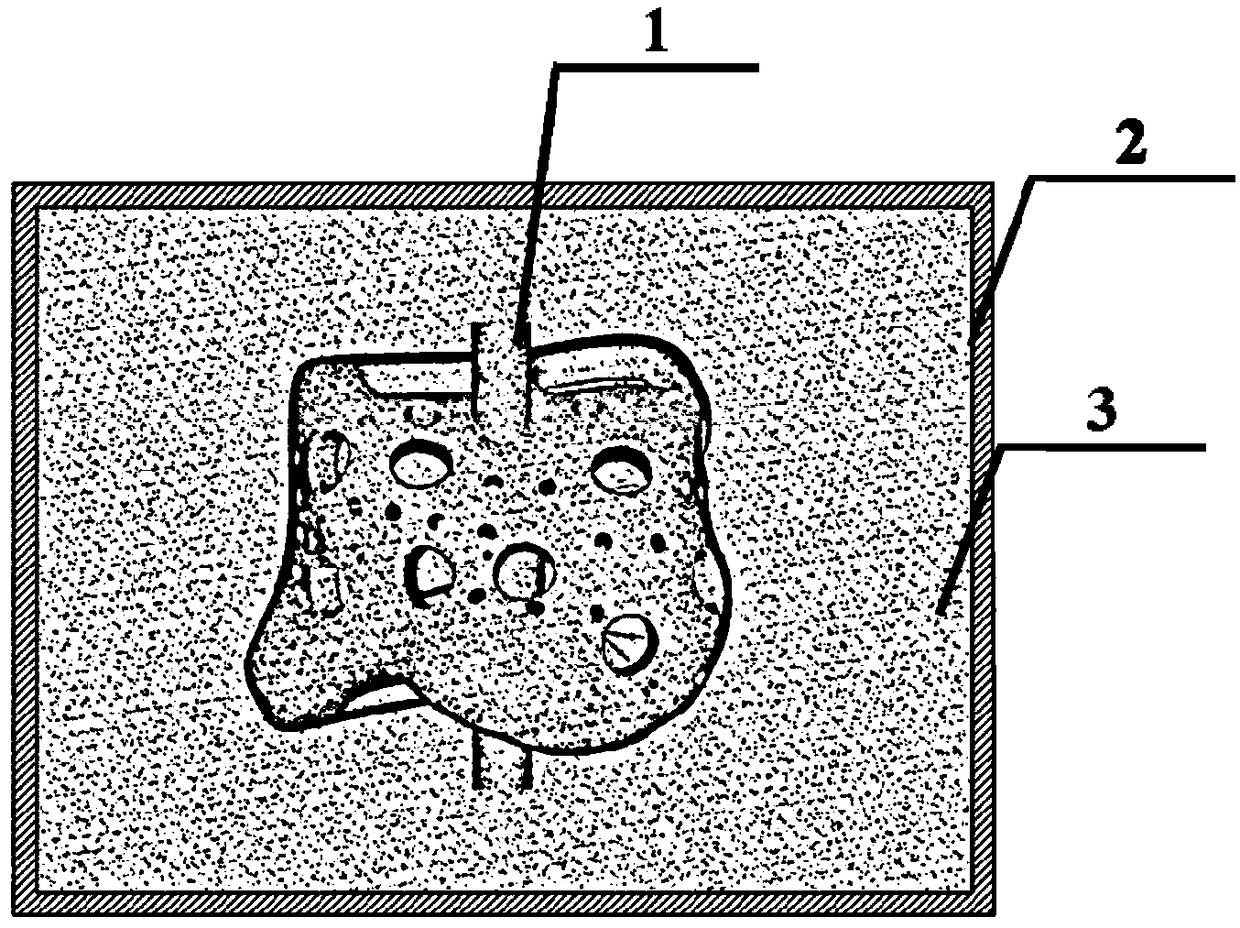

[0041] This embodiment includes the following steps:

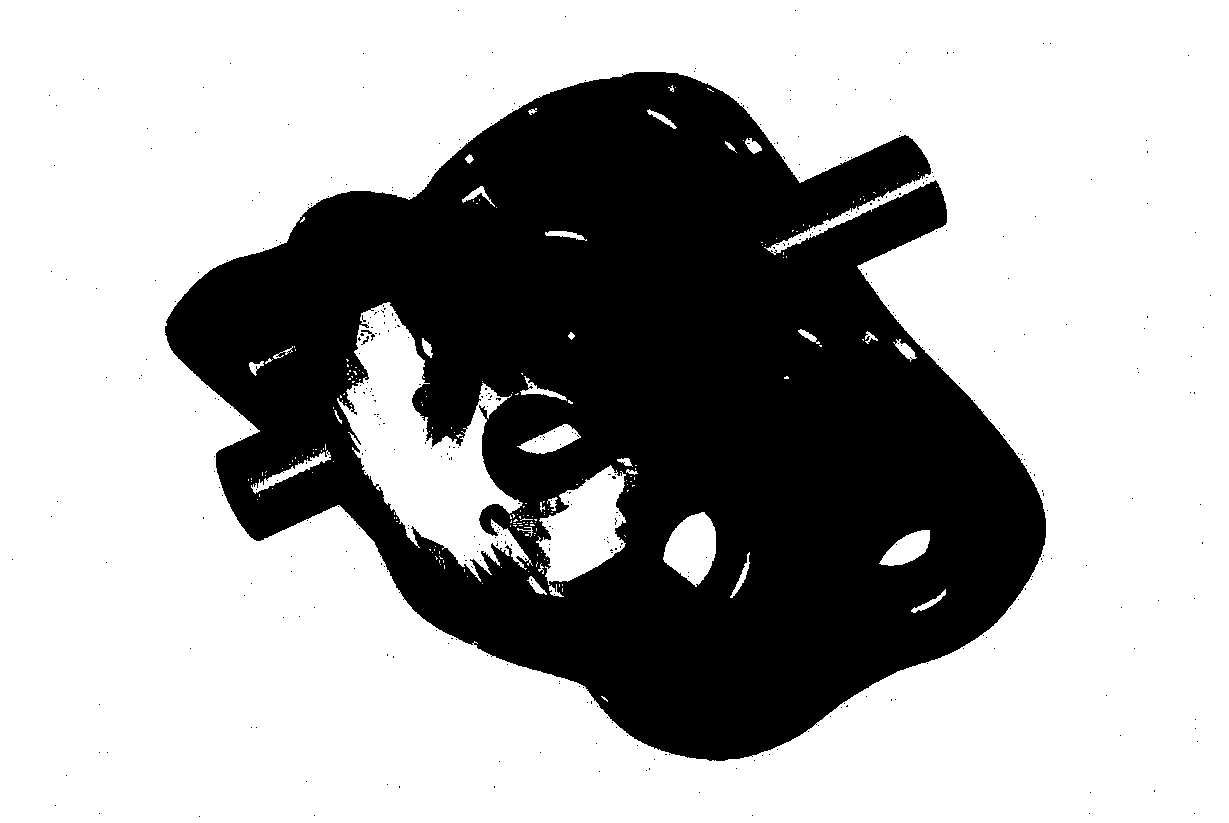

[0042] Step 1. Obtain the three-dimensional geometric model of the porous titanium alloy ankle pad that needs to be prepared by using the method of three-dimensional reconstruction of CT data, such as figure 1 As shown in Fig. 1, model slices and supports are added sequentially to obtain data files in stl format for each slice, and then according to the data files in stl format for each slice, Ti-6Al-4V alloy powder is used as raw material, and the area is selected by electron beam The porous Ti-6Al-4V alloy skeleton is prepared by melting and forming; the pore diameter of the porous Ti-6Al-4V alloy skeleton is 300 μm, and the porosity is 60%;

[0043] Step 2: Carry out chemical corrosion to the porous Ti-6Al-4V alloy skeleton prepared in step 1, and then carry out ultrasonic cleaning and drying successively; It is formed by mixing 68% nitric acid and water according to the volume ratio of 1:3:30, and the chemical corrosi...

Embodiment 2

[0048] This embodiment includes the following steps:

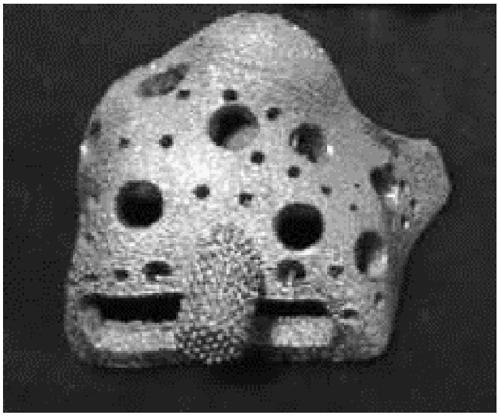

[0049] Step 1. Obtain the three-dimensional geometric model of the porous titanium metal acetabular cup spacer that needs to be prepared by using the method of standardized modeling, and sequentially perform model slice and support addition processing to obtain data files in stl format for each slice, and then according to each The data file in layer-cut stl format, using pure titanium powder as raw material, adopts laser selective melting forming method to prepare porous titanium skeleton; the pore diameter of the porous titanium skeleton is 1000 μm, and the porosity is 90%;

[0050] Step 2, chemically corroding the porous titanium skeleton prepared in step 1, and then performing ultrasonic cleaning and drying in sequence; the corrosion solution used in the chemical corrosion has a mass concentration of 40% hydrofluoric acid, 68% nitric acid and Water is mixed according to the volume ratio of 1:6:60, and the time of chemi...

Embodiment 3

[0054] This embodiment includes the following steps:

[0055] Step 1. Obtain the three-dimensional geometric model of the porous titanium alloy acetabular cup that needs to be prepared by digital three-dimensional scanning method, and sequentially perform model slice and support addition processing to obtain data files in stl format for each slice, and then according to each slice The data file in stl format, using TiTa alloy powder as raw material, adopts electron beam selective melting forming method to prepare porous TiTa alloy skeleton; the pore diameter of the porous TiTa alloy skeleton is 500 μm, and the porosity is 60%;

[0056] Step 2. Carry out chemical corrosion to the porous TiTa alloy skeleton prepared in step 1, and then carry out ultrasonic cleaning and drying successively; Nitric acid and water are mixed according to the volume ratio of 1:5:45, and the time of the chemical corrosion is 30min;

[0057] Step 3. Completely embed the dried porous TiTa alloy skeleto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com