A preparation method of an alumina-coated manganese-doped lithium iron phosphate cathode material

A lithium iron phosphate, cathode material technology, applied in battery electrodes, electrochemical generators, electrical components, etc., can solve the problem of difficult to meet the requirements of high-rate charge and discharge of power batteries, affect the electrode cycle stability and cycle efficiency, iron phosphate The problem of low diffusion rate of lithium and lithium ions can improve stability and cycle efficiency, improve electrochemical performance, and avoid direct contact reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

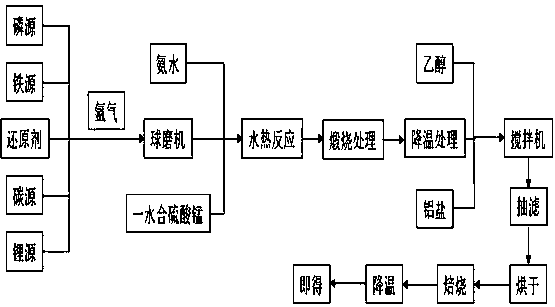

[0027] A method for preparing an alumina-coated manganese-doped lithium iron phosphate cathode material, comprising the following steps in sequence:

[0028] (1) Add ammonium hydrogen phosphate, ferrous oxalate, and lithium carbonate in a mass ratio of 2:2:5, glucose as the carbon source, and ethanol as the reducing agent. , ball milling, after the ball milling is completed, a manganese-doped lithium iron phosphate precursor is obtained;

[0029] (2) Add manganese sulfate monohydrate as the manganese source doped with lithium iron phosphate to the manganese-doped lithium iron phosphate precursor solution obtained in step (1), and add ammonia water to the iron phosphate that has been dripped with manganese sulfate monohydrate In the lithium precursor solution, the pH of the solution is adjusted to be 8, and the hydrothermal reaction is carried out. The reacted slurry is placed in a blast oven for drying, and after drying, it is calcined. Before calcining, it is pre-calcined und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com