A Zr-based high-entropy alloy coating that improves the life of a hot forging die and its preparation method

A technology of hot forging die and high-entropy alloy, which is applied in metal material coating process, coating, solid diffusion coating and other directions, can solve the problem of high temperature, heavy load, insufficient coating bonding strength and life extension effect of hot forging die. It can achieve the effect of improving high temperature softening resistance and corrosion resistance, excellent thermal stability, and improving diffusion barrier properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

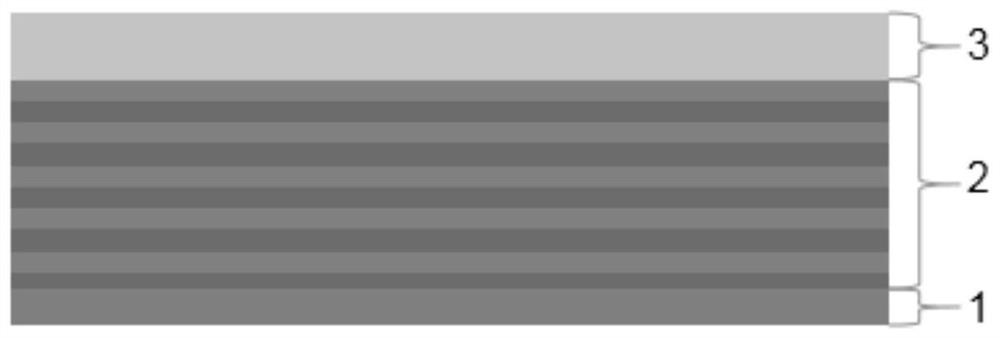

Image

Examples

Embodiment 1

[0065] Preparation method of surface Zr-based high-entropy alloy coating for improving the life of hot forging die, including the following preparation steps:

[0066]Step 1: Select H13 material hot forging mold as the substrate, select 220 mesh corundum sand, 0.6Pa pressure to blast the mold surface, remove the surface oil and passivation layer; use the 500 mesh abrasive polishing machine to grind and polish the mold for 10min; select the automatic ultrasonic cleaning line to clean the mold, the specific process is to heat the lye to 60 °C, spray and clean the hot forging mold for 10 min; and then ultrasonically clean the hot forging mold to 60 °C in the lye for 5 min Take out the hot forging mold for water rinsing; ultrasonically clean the hot forging mold at 60 °C for 10 min; take out the hot forging mold for 5 min of clean water; ultrasonically clean the hot forging mold in pure water for 5 min; dry the hot forging mold after pure water and set aside;

[0067] Step 2: Nitridi...

Embodiment 2

[0075] Preparation method of surface Zr-based high-entropy alloy coating for improving the life of hot forging die, including the following preparation steps:

[0076]Step 1: Select H13 material hot forging mold as the substrate, select 320 mesh corundum sand, 0.8Pa pressure to blast the mold surface, remove the surface oil and passivation layer; use the 500 mesh abrasive polishing machine to grind and polish the mold for 10min; select the automatic ultrasonic cleaning line to clean the mold, the specific process is to heat the lye to 60 °C, spray and clean the hot forging mold for 10 min; and then ultrasonically clean the hot forging mold to 60 °C alkali for 5 min Take out the hot forging mold for water rinsing; ultrasonically clean the hot forging mold at 60 °C for 10 min; take out the hot forging mold for 5 min of clean water; ultrasonically clean the hot forging mold in pure water for 5 min; dry the hot forging mold after pure water and set aside;

[0077] Step 2: Nitriding t...

Embodiment 3

[0085] Preparation method of surface Zr-based high-entropy alloy coating for improving the life of hot forging die, including the following preparation steps:

[0086]Step 1: Select H13 material hot forging mold as the substrate, select 420 mesh corundum sand, 0.6Pa pressure to blast the mold surface, remove the surface oil and passivation layer; use the 500 mesh abrasive polishing machine to grind and polish the mold for 15min; choose the automatic ultrasonic cleaning line to clean the mold, the specific process is to heat the lye to 60 ° C, spray cleaning the hot forging mold for 8min; and then ultrasonically clean the hot forging mold to 60 ° C in the lye for 60 minutes Take out the hot forging mold for rinsing with clean water; ultrasonically clean the hot forging mold at 60 °C for 8min; take out the hot forging mold for 7min; ultrasonically clean the hot forging mold in pure water for 7min; ultrasonically clean the hot forging mold in pure water for 7min; dry the hot forging...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com