EBM molded titanium implant and preparation method and application thereof

A technology of implants and titanium alloys, applied in prostheses, pharmaceutical formulations, surface reactive electrolytic coatings, etc., can solve problems such as easy trapping in holes, rough surface of titanium implants, and damage to normal functions of the human body. Reduce the risk of implant failure, improve resource utilization, and reduce the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] In view of this, in a specific embodiment of the present invention, a kind of preparation method of EBM shaped titanium implant is provided, and described method comprises:

[0038] (1) EBM molding of titanium implants: using metal titanium or titanium alloy spherical powder as raw material, the implants are printed out by EBM molding;

[0039] Among them, the electron beam power is 900W, the spot diameter is 100μm, the layer thickness is 50μm, and the scanning speed is 800mm / s;

[0040] (2) Ultrasonic acid etching: use hydrochloric acid, sulfuric acid, hydrofluoric acid, nitric acid, oxalic acid, hydrogen peroxide and other different acids or oxidants to mix one or more kinds of acid etching solution, and immerse the formed implant in the etching solution. liquid. The temperature is 10°C to 80°C, and the treatment time is 1 to 30 minutes. Ultrasonic waves are introduced into the acid etching process, the ultrasonic frequency is 40kHz, and the power is 100-600W.

[0...

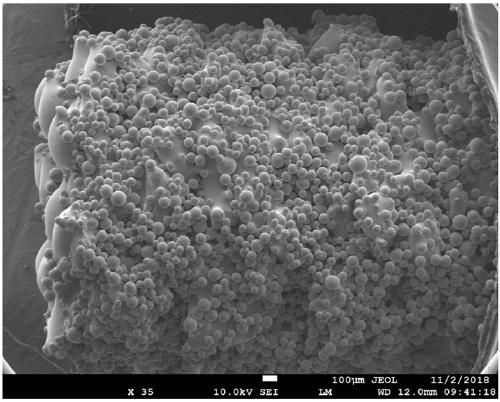

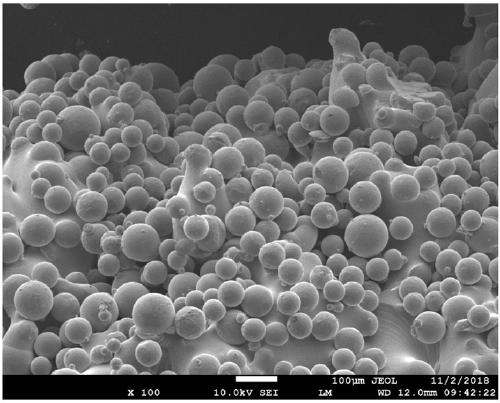

Embodiment 1

[0055] (1) Titanium implant EBM molding: Use Solidworks software to draw a titanium rod model with a size of Φ2*3, use 3-matic software to add porous array elements on the titanium rod model through Boolean operations, set the aperture to 0.18mm, and The rod diameter is 0.2mm and the porosity is 55%. After importing the EBM molding equipment, the titanium alloy Ti6Al4V spherical powder is used as the raw material for printing. The powder diameter is 45-106μm, the electron beam power is 900W, the spot diameter is 100μm, the layer thickness is 50μm, and the scanning speed is 800mm / s.

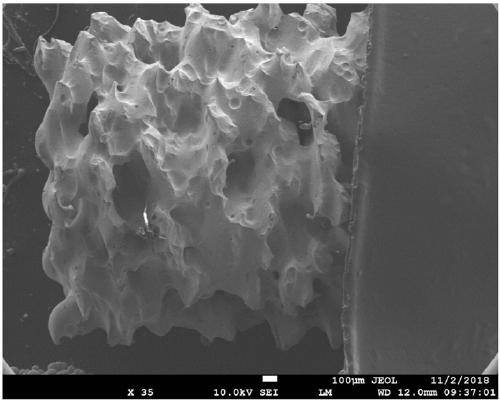

[0056] (2) Ultrasonic acid etching: Prepare hydrofluoric acid with a mass fraction of 40% and 37% hydrochloric acid, mix them with water at a volume ratio of 1:1:18, and immerse the formed implant in the acid solution for corrosion. The temperature is 30°C, and the acid etching time is 5 minutes. Ultrasonic waves are introduced during the acid etching process, the ultrasonic frequency is 40kHz, ...

Embodiment 2

[0060] (1) Titanium implant EBM molding: Use Solidworks software to draw a titanium rod model with a size of Φ2*3, use 3-matic software to add porous array elements on the titanium rod model through Boolean operations, set the aperture to 0.18mm, and The rod diameter is 0.2mm and the porosity is 55%. After importing the EBM molding equipment, the titanium metal spherical powder is used as the raw material for printing. The powder diameter is 50-110μm, the electron beam power is 900W, the spot diameter is 100μm, the layer thickness is 50μm, and the scanning speed is 800mm / s.

[0061] (2) Ultrasonic acid etching: Prepare sulfuric acid with a mass fraction of 98% and 35% hydrochloric acid, mix them with water at a volume ratio of 0.1:1:10, and immerse the formed implant in the acid solution for corrosion. The temperature is 40°C, and the acid etching time is 10 minutes. Ultrasonic waves are introduced into the acid etching process, the ultrasonic frequency is 40kHz, and the pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com