Flurbiprofen axetil emulsion for injection and preparation method thereof

A technology for flurbiprofen axetil and injection is applied in the field of flurbiprofen axetil injection emulsion and its preparation, which can solve problems such as unfavorable drug efficacy, influence on drug targeting effect, etc., so as to improve drug encapsulation efficiency and improve Emulsifying effect, milk uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

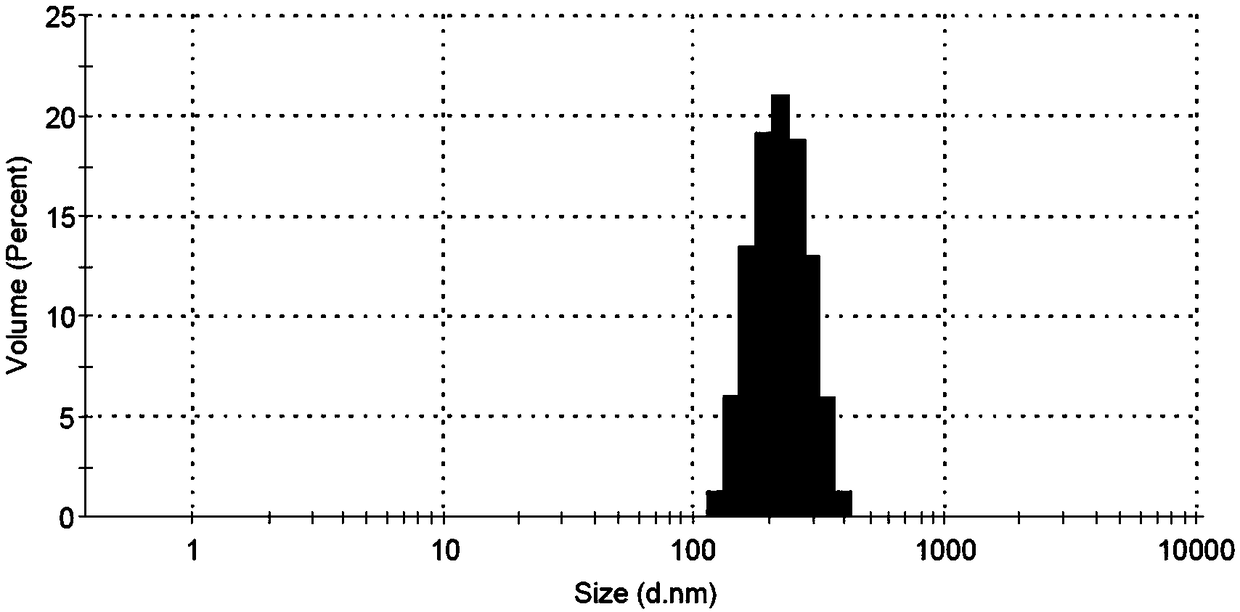

Image

Examples

Embodiment 1

[0066] The present embodiment provides a kind of flurbiprofen axetil injection emulsion, and its prescription is as follows:

[0067]

[0068]

[0069] The preparation method is as follows:

[0070] (1) Stir and mix the prescribed amount of flurbiprofen axetil, refined soybean oil, egg yolk lecithin, and dioleoylphosphatidylserine at 60° C. for 30 minutes under nitrogen-filled conditions to obtain a uniform oil phase (122.1 g) for later use;

[0071] (2) Stir and mix the glycerin and water for injection in the prescribed amount, and heat to 60°C for later use;

[0072] (3) Under the protection of nitrogen, 48.8g of the oil phase of step (1) was sheared and mixed with the water phase of step (2) at 4000rpm for 10min to obtain crude milk A; crude milk A was sheared with 36.6g of the oil phase of step (1) at 6000rpm again Cut and mix for 10 minutes to obtain crude milk B; shear and mix crude milk B with 36.6 g of the oil phase of step (1) at 8000 rpm for 20 minutes again t...

Embodiment 2

[0076] The present embodiment provides a kind of flurbiprofen axetil injection emulsion, and its prescription is as follows:

[0077]

[0078] The preparation method is as follows:

[0079] (1) Stir and mix the prescribed amount of flurbiprofen axetil, olive oil, soybean lecithin, and dipalmitoylphosphatidic acid at 65° C. for 20 minutes under nitrogen-filled conditions to obtain a uniform oil phase (156 g) for subsequent use;

[0080] (2) Stir and mix the sucrose and water for injection of the prescribed amount evenly, and heat to 65°C for later use;

[0081] (3) Under the protection of nitrogen, 78g of the oil phase of step (1) was sheared and mixed with the water phase of step (2) at 5000rpm for 15min to obtain crude milk A; crude milk A was again sheared and mixed with 39g of the oil phase of step (1) at 7000rpm 15min to obtain crude milk B; crude milk B was sheared and mixed with 39g of the oil phase of step (1) at 9000rpm for 30min again to obtain colostrum;

[0082...

Embodiment 3

[0085] The present embodiment provides a kind of flurbiprofen axetil injection emulsion, and its prescription is as follows:

[0086]

[0087] The preparation method is as follows:

[0088] (1) Stir and mix the prescribed amount of flurbiprofen axetil, medium-chain triglycerides, refined soybean oil, macrogol stearate, and sphingomyelin at 70°C for 15 minutes under nitrogen filling to obtain a uniform Oil phase (125.8g) is standby;

[0089] (2) Stir and mix the prescribed amount of mannitol and water for injection evenly, and heat to 70°C for later use;

[0090] (3) Under the protection of nitrogen, 75.5g of the oil phase of step (1) was sheared and mixed with the water phase of step (2) at 6000rpm for 20min to obtain crude milk A; crude milk A was sheared again with 25g of the oil phase of step (1) at 8000rpm Mix for 20 minutes to obtain crude milk B; shear and mix crude milk B with 25 g of the oil phase of step (1) at 10000 rpm for 30 minutes again to obtain colostrum; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com