Terbium doped yttrium strontium triborate green fluorescent powder, and preparation method thereof

A technology of green fluorescent powder and yttrium triborate, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of high color temperature and low color rendering index, and achieve the effects of high luminous intensity, good luminous performance and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] According to chemical formula Sr 3 Y 0.99 (BO 3 ) 3 : Stoichiometric ratio of 0.01Tb, use an electronic balance to accurately weigh SrCO 3 , Y 2 o 3 、H 3 BO 3 , Tb 4 o 7 , wherein the purity of rare earth oxides is 99.99%, and the rest are analytically pure. After grinding and mixing the above raw materials evenly, put them into a corundum crucible, place them in a rapid heating resistance furnace, raise the temperature to 1200°C in an air atmosphere at a rate of 5°C / min, keep it warm for 5 hours, and then cool with the furnace, and wait for the sample to cool to room temperature. Take out the sample and grind it again to get Tb 3+ Doped yttrium strontium triborate green phosphor.

Embodiment 2

[0031] According to chemical formula Sr 3 Y 0.98 (BO 3 ) 3 : Stoichiometric ratio of 0.02Tb, use an electronic balance to accurately weigh SrCO 3 , Y 2 o 3 、H 3 BO 3 , Tb 4 o 7 , wherein the purity of rare earth oxides is 99.99%, and the rest are analytically pure. Grind and mix the above raw materials evenly, put them into a corundum crucible, place them in a rapid heating resistance furnace, raise the temperature to 1250°C in an air atmosphere at a rate of 8°C / min, keep it warm for 5 hours, then cool with the furnace, and wait for the sample to cool to room temperature. Take out the sample and grind it again to get Tb 3+ Doped yttrium strontium triborate green phosphor.

Embodiment 3

[0033] According to chemical formula Sr 3 Y 0.96 (BO 3 ) 3: Stoichiometric ratio of 0.04Tb, use an electronic balance to accurately weigh SrCO 3 , Y 2 o 3 、H 3 BO 3 , Tb 4 o 7 , wherein the purity of rare earth oxides is 99.99%, and the rest are analytically pure. Grind and mix the above raw materials evenly, put them into a corundum crucible, place them in a rapid heating resistance furnace, raise the temperature to 1250°C in an air atmosphere at a rate of 10°C / min, keep it warm for 5 hours, then cool with the furnace, and wait for the sample to cool to room temperature. Take out the sample and grind it again to get Tb 3+ Doped yttrium strontium triborate green phosphor.

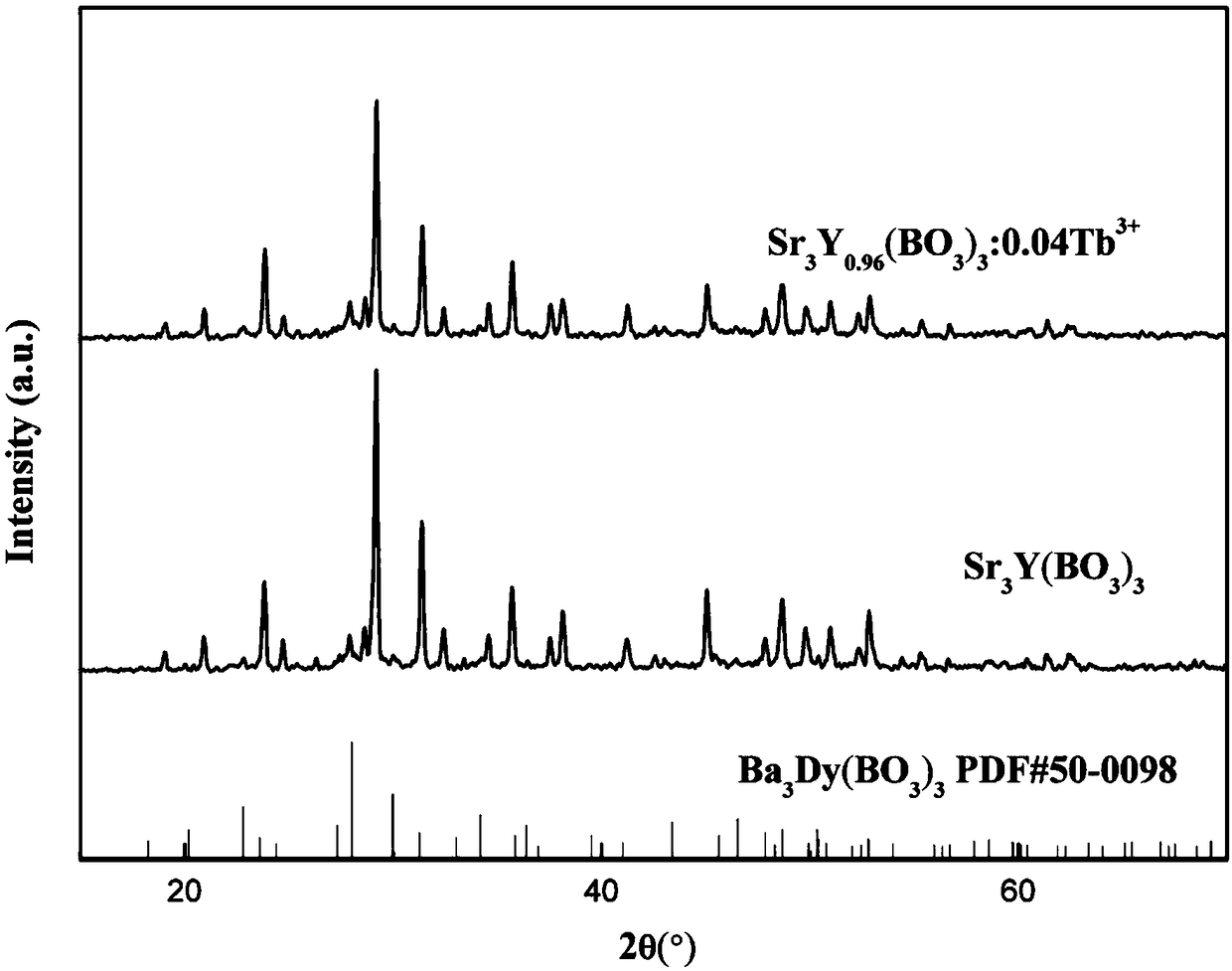

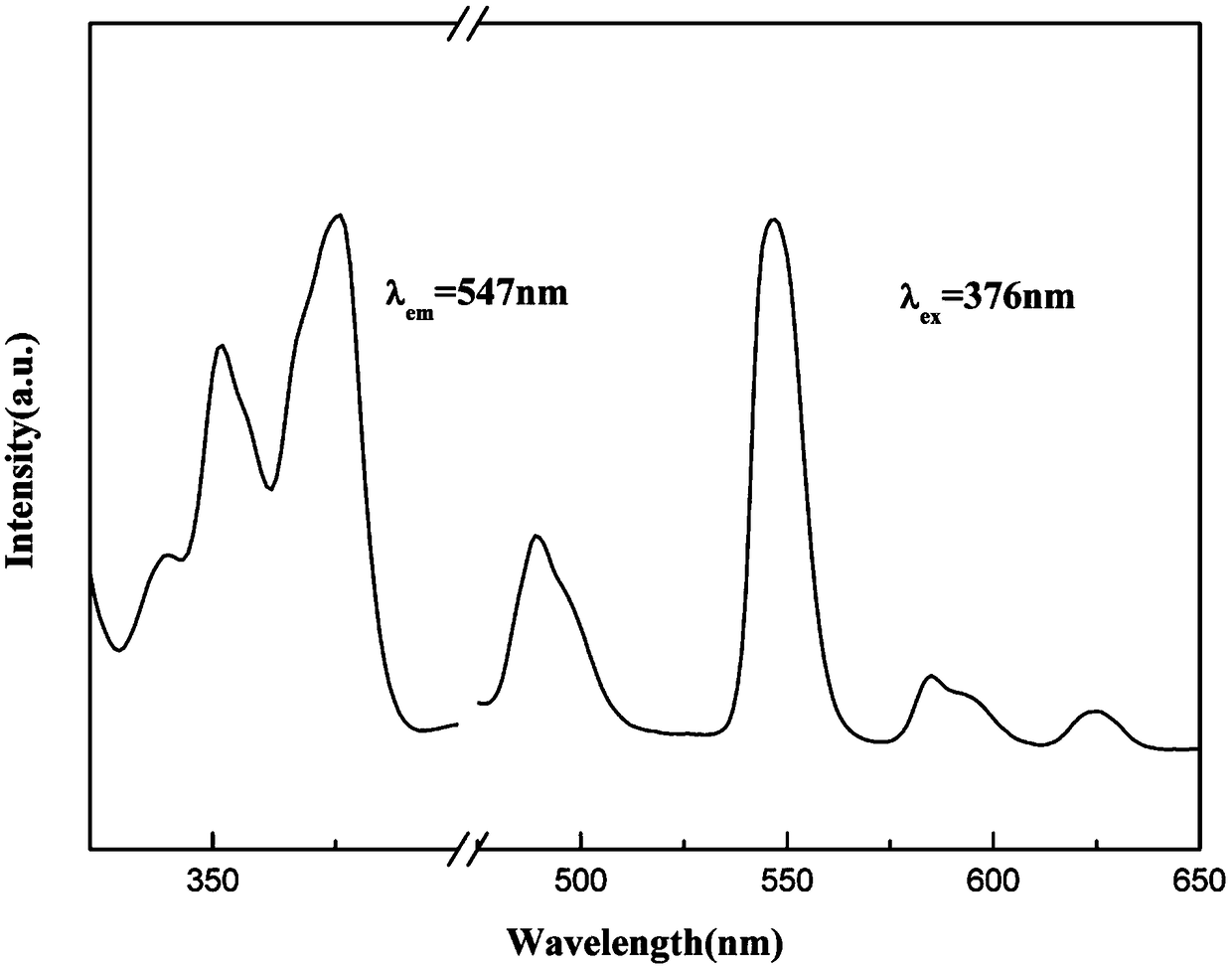

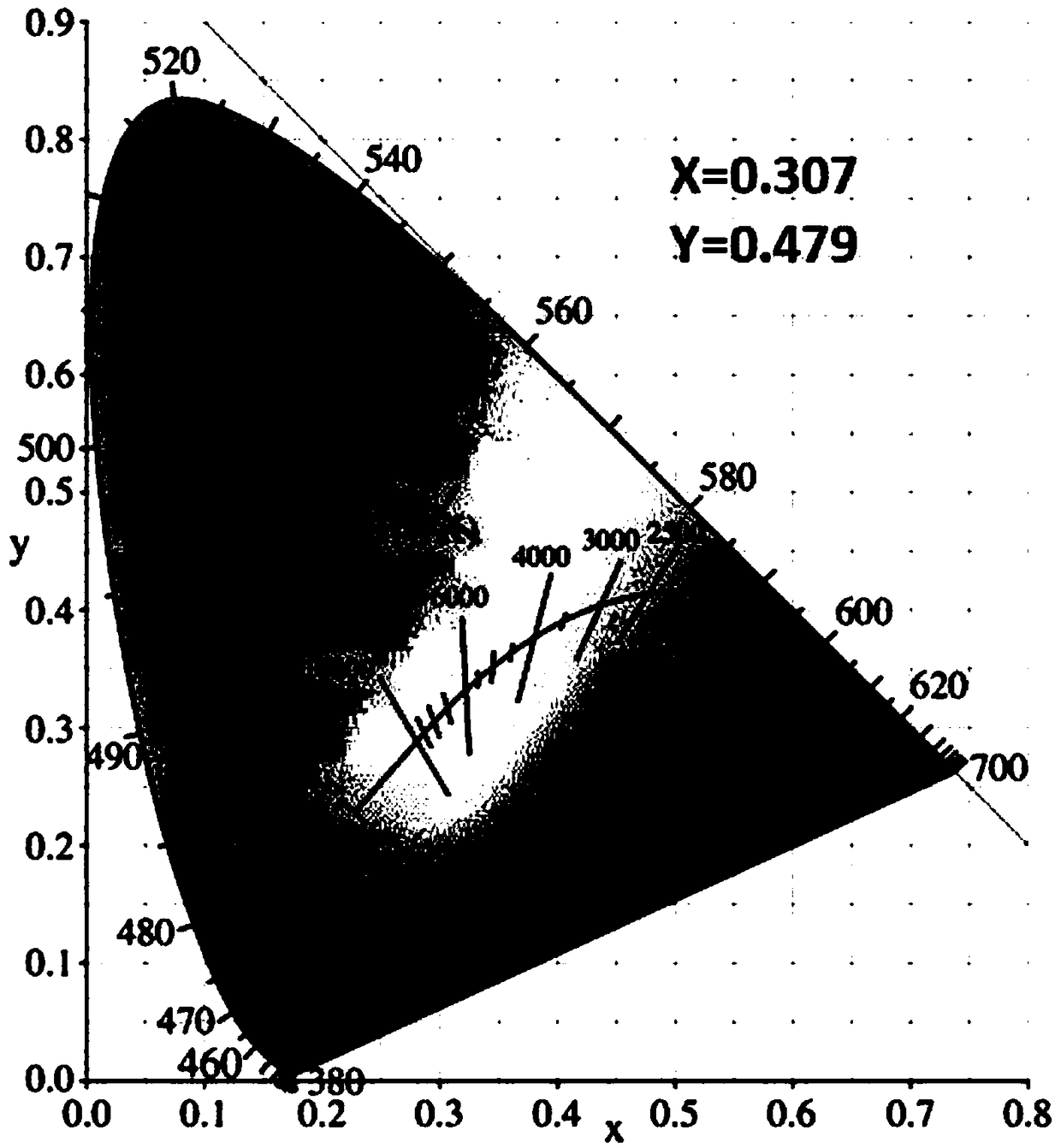

[0034] figure 1 Is the Sr prepared in Example 3 3 Y 0.96 (BO 3 ) 3 : 0.04Tb phosphor and Sr 3 Y(BO 3 ) 3 The X-ray diffraction pattern of the matrix and the Ba 3 Dy(BO 3 ) 3 Standard card (PDF#50-0098) comparison chart. Sr is currently not found in the PDF card library 3 Y(BO 3 ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com