Preparation method of rinse-free coarse cereal instant nutritional rice and production method of instant cooked rice

A technology of nutritious rice and miscellaneous grains, applied in the direction of food science, food composition, application, etc., can solve the problems of unsatisfactory taste, nutrition, flavor, and digestion characteristics, single nutritional composition, complex and time-consuming cooking process, etc., to achieve The preparation and processing method is green and environmentally friendly, the preparation and processing method is simple, and the effect of shortening the cooking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

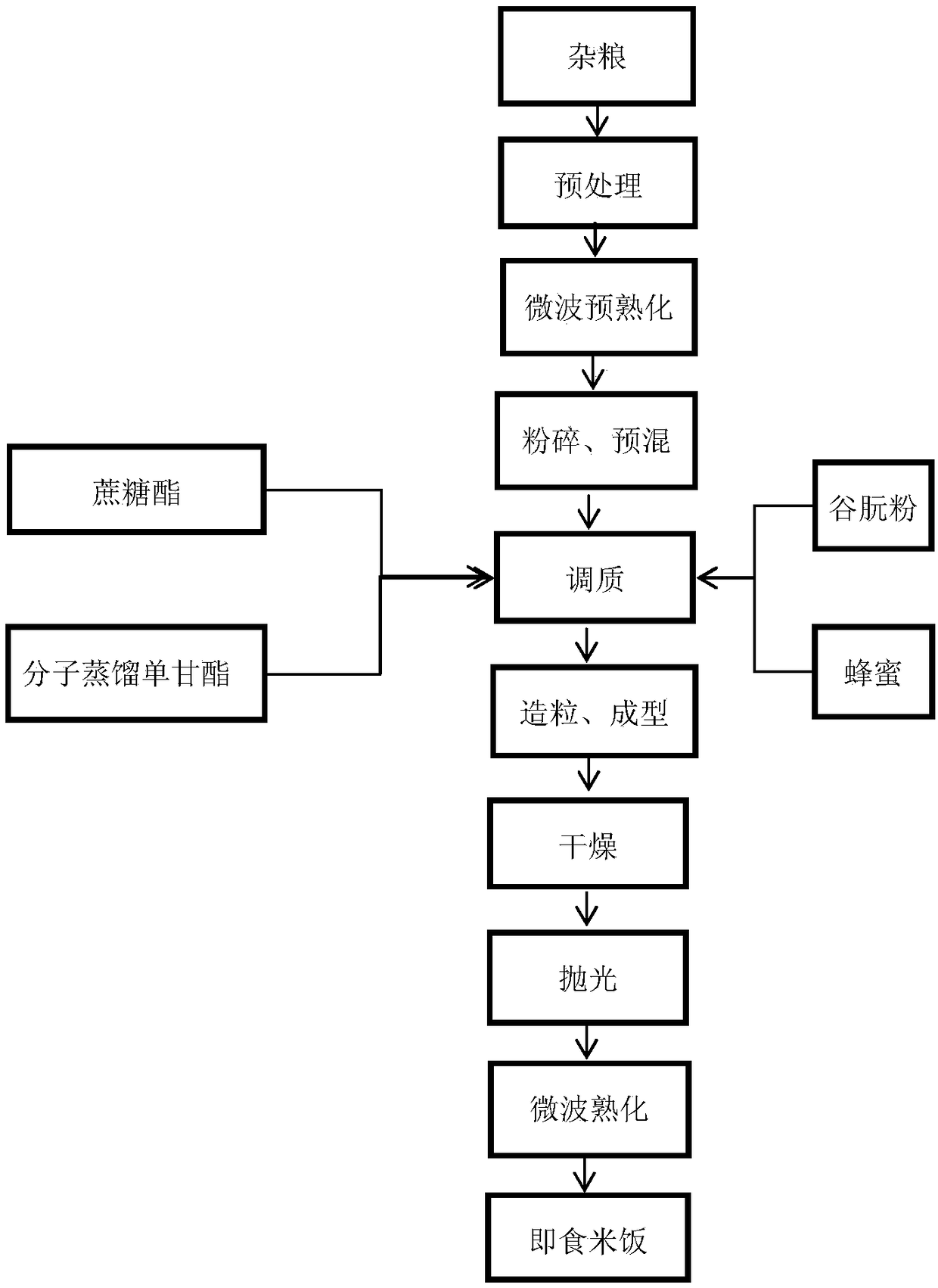

Method used

Image

Examples

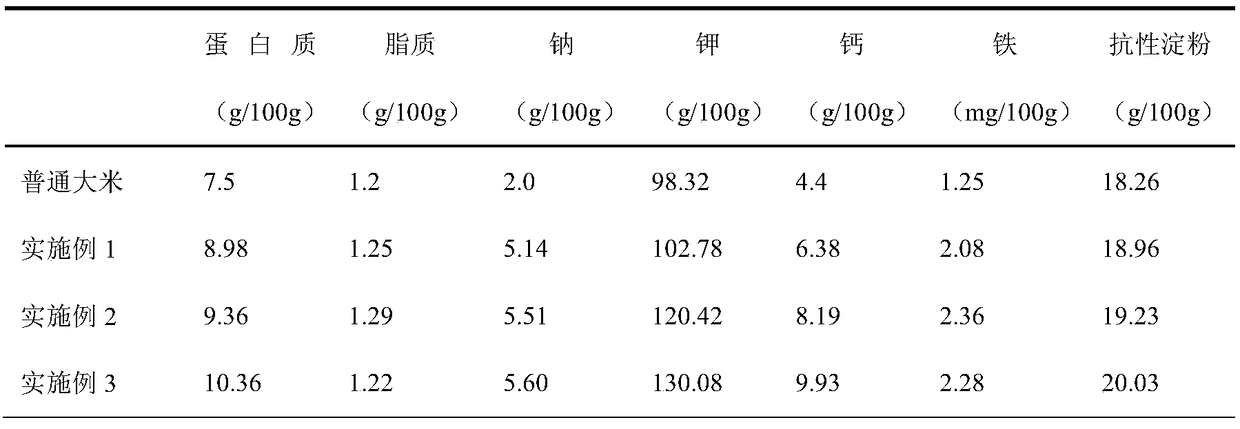

Embodiment 1

[0030] Brown rice, adzuki bean, and black bean are cleaned, removed, and weighed, and pre-cured in a microwave power of 1000w for 80s, crushed to 150 microns by a grinder, and accurately weighed 1,800g of brown rice flour, 450g of adzuki bean flour, and 450g of black bean flour , gluten powder 150g, add respectively 30g of Poria cocos powder, ginkgo powder, Chinese yam powder, pueraria powder, gorgon powder, 30g of honey, and 30g of compound improver are placed in the mixer and mixed, and the moisture of the mixed material is adjusted to 25%; The material is sent into the twin-screw extruder for molding and granulation, and the working temperature of each section of the twin-screw extruder is set: the temperature in zone I is 40°C, the temperature in zone II is 80°C, the temperature in zone III is 120°C, and the temperature in zone IV is 120°C. Zone V is 40°C, Zone VI is 20°C, the screw speed is 200rpm, and extruded through a rectangular die hole. The compound nutritional rice ...

Embodiment 2

[0032] Brown rice, adzuki bean, and black bean are cleaned, removed, and weighed, and pre-cured in a microwave power of 1000w for 80s, crushed to 220 microns by a grinder, and accurately weighed 1650g of brown rice flour, 300g of adzuki bean flour, and 300g of black bean flour , gluten powder 240g, add respectively 90g of Poria cocos powder, ginkgo powder, Chinese yam powder, pueraria powder, gorgon powder, 60g of honey, and 45g of compound improver are placed in the mixer and mixed, and the moisture content of the mixed material is adjusted to 30%; The material is fed into the twin-screw extruder for molding and granulation, and the working temperature of each section of the twin-screw extruder is set: 50°C for zone I, 90°C for zone II, 130°C for zone III, 130°C for zone IV, and 130°C for zone V 50°C, 30°C in zone VI, screw speed at 300rpm, extruded through a rectangular die hole, the compound nutritional rice is dried by low-temperature air flow, the hot air speed is 1.2m / s, ...

Embodiment 3

[0034] Brown rice, adzuki bean, and black bean are cleaned, removed and weighed, and pre-cooked under microwave power of 1000w for 80s, crushed to 240 microns by a pulverizer, and accurately weigh 1500g of brown rice flour, 150g of adzuki bean flour, and black bean flour. 150g, 300g of gluten powder, respectively add 150g of poria powder, ginkgo powder, Chinese yam powder, pueraria powder, and gorgon powder, 90g of honey, and 60g of compound improver and mix in the mixer, adjust the moisture content of the mixture to 35%; Send the material into the twin-screw extruder for molding and granulation, and set the working temperature of each section of the twin-screw extruder: 60°C for zone I, 100°C for zone II, 140°C for zone III, 140°C for zone IV, and 140°C for zone V Zone 60°C, VI zone 30°C, screw speed 350rpm, extruded through a rectangular die orifice, compound nutritional rice is dried by low-temperature airflow, hot air speed is 1.2m / s, hot air temperature is 50°C and dried f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com