Strip-shaped grate concrete filled steel tube combined structure shear wall and preparation method thereof

A technology of steel tube concrete and composite structure, which is applied in the direction of walls, building components, building structures, etc., and can solve the problems of complex structure of double-layer steel plate shear wall, unreliable force of tensile structure, and lack of restoring force strength. , to achieve the effects of avoiding out-of-plane buckling damage, simple manufacturing and processing methods, and improved structural ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

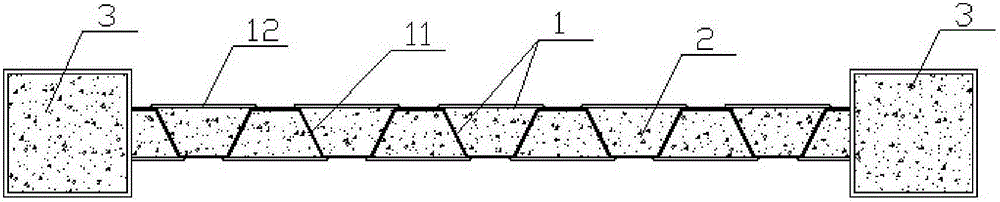

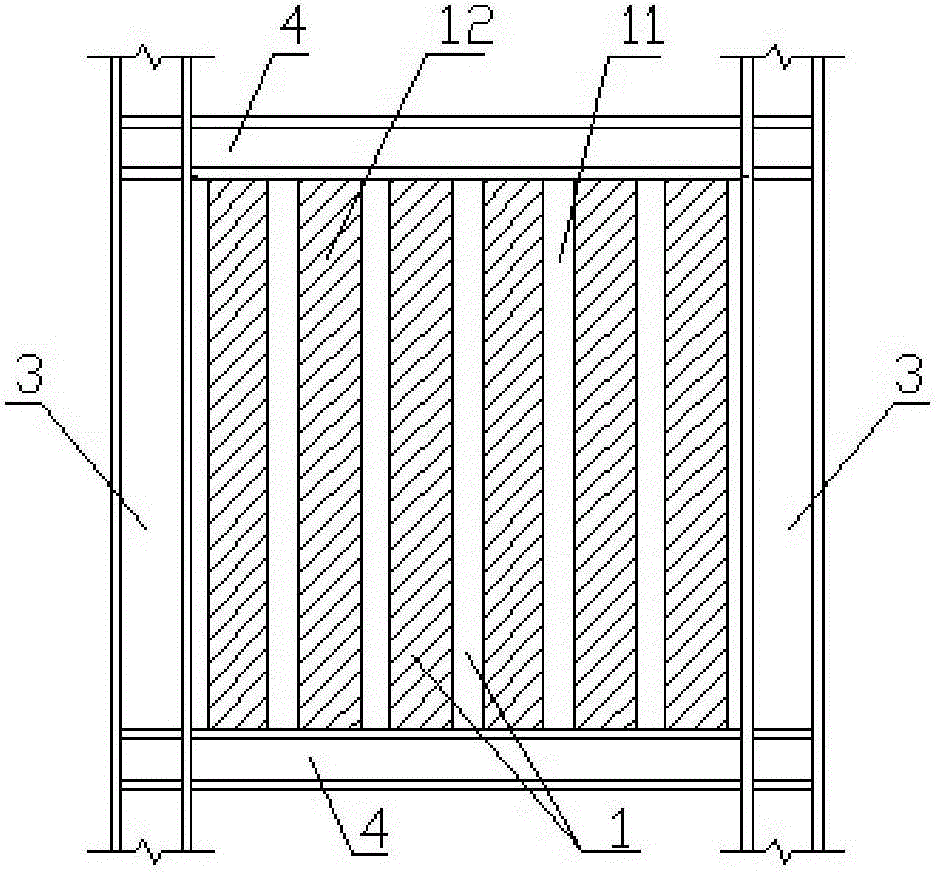

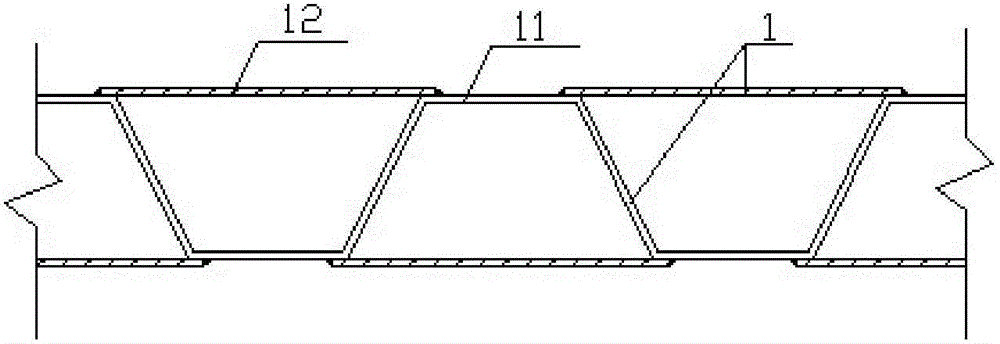

[0043] The shear wall of the composite structure of steel pipe concrete with elongated grid includes steel pipe wall plate 1 with elongated grid, reinforced concrete column 2 inside the pipe, edge steel column 3 and edge steel beam 4 . The elongated grid steel pipe wall panel 1 is composed of corrugated steel plate 11 and several steel strip cover plates 12 vertically welded and connected. , forming a long-strip steel structure hollow panel wall shape with multiple cavities, the strip-shaped grid steel pipe wall panel 1 contains two or more cavities, and the space of the strip-shaped grid steel pipe wall panel 1 Reinforced concrete columns 2 are arranged in the cavity, the left and right sides of the elongated grid steel pipe wall panel 1 are welded to the edge steel column 3, and the upper and lower sides of the elongated grid steel pipe wall panel 1 are welded to the edge steel beam 4;

[0044] In-pipe reinforced concrete column 2 includes in-pipe concrete 21, corrugated ste...

Embodiment 2

[0046] The preparation method of the above-mentioned elongated grid steel pipe concrete composite structure shear wall comprises the following steps:

[0047] Step 1: In the processing plant, tidy up the site, organize the construction materials, and carry out blanking of the corrugated steel plate 11 according to the design requirements. 11 and the inner surface of the steel strip cover plate 12 are welded firmly, and then, several steel strip cover plates 12 are completely covered with the notch of the corrugated steel plate 11, and the two are welded and connected firmly, and the vertical steel bar 24 in the pipe is inserted into the tie hoop The four corners of the rib-shaped enclosing frame form a strip-shaped grid steel pipe wall panel 1 with a welded steel skeleton;

[0048] Step 2: pouring self-compacting high-strength concrete into the cavity of the strip-shaped grid steel pipe wall panel 1 to form the concrete 21 in the pipe, curing the concrete, and waiting for the ...

Embodiment 3

[0051] A 100-story super high-rise steel structure building adopts a frame shear wall steel structure system. The frame columns are square concrete-filled steel tube columns, and the frame beams are made of H-shaped steel. The height of the bottom three floors is 4.5 meters, and the height of the rest is 3.6 meters. Because it is a super high-rise building, in order to resist wind and earthquake, multiple new strip-shaped grid steel pipe concrete composite structure shear walls are set up. One of the shear walls has a net length of 5.4 meters, and a long grid steel pipe wall panel composed of trapezoidal corrugated steel plates is selected, such as Figure 1 to Figure 5 The dimensions of the corrugated steel plate on the bottom fifteen floors are 900mm in wavelength, 300mm in wave height, 300mm in horizontal length of the straight plate section, 150mm in projected length of the inclined plate section, and 650mm in width of the steel strip cover plate; 800mm, the wave height is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com