Graphene and rare earth scandium synergistically enhanced Al-Si-Mg cast aluminum alloy and preparation method thereof

A technology for casting aluminum alloy and graphene, applied in the field of casting aluminum alloy, can solve the problems of low density of parts, poor material properties, easy segregation, etc., to improve the plasticity of the alloy, improve the utilization rate of the alloy, and achieve mild conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

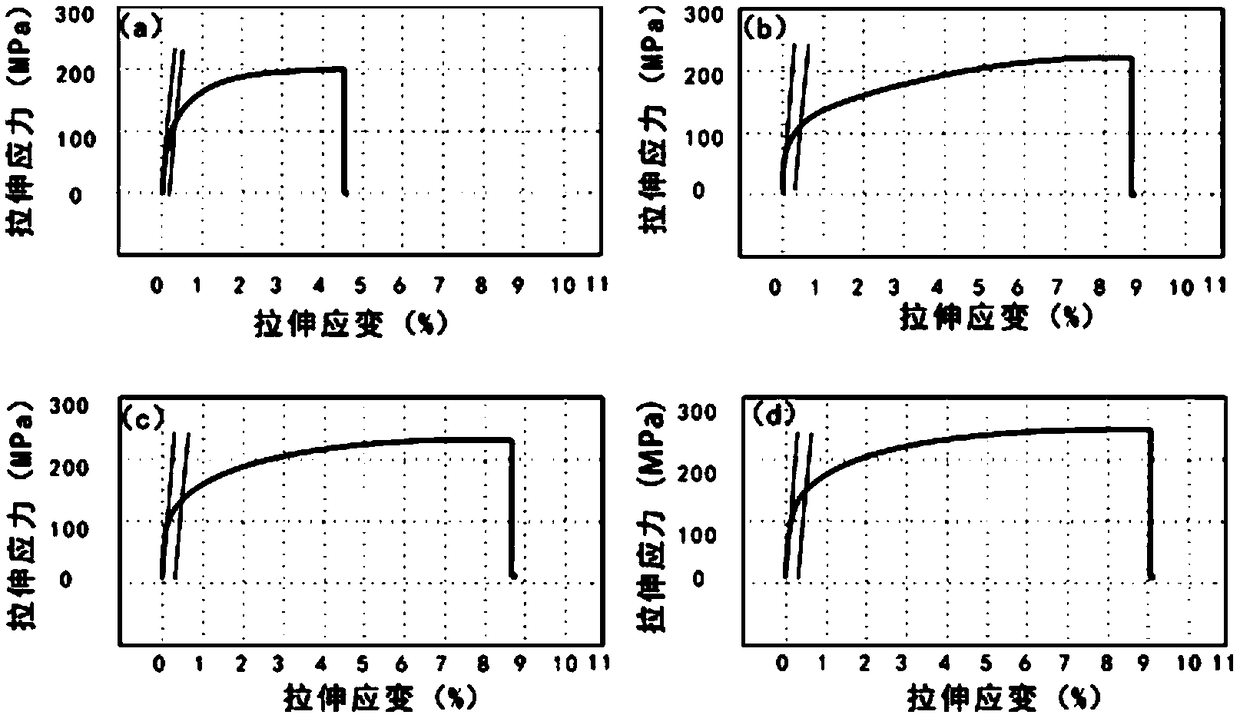

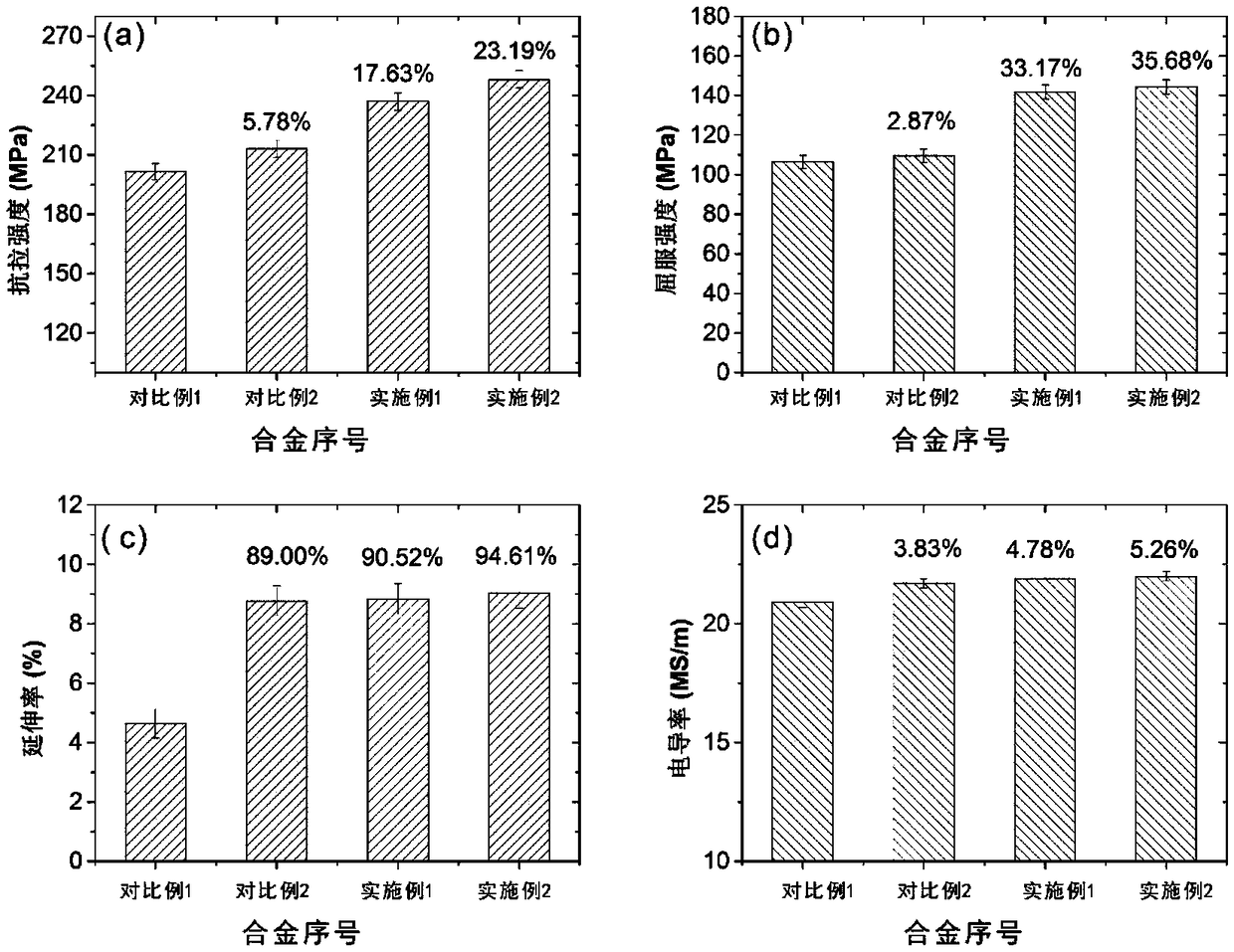

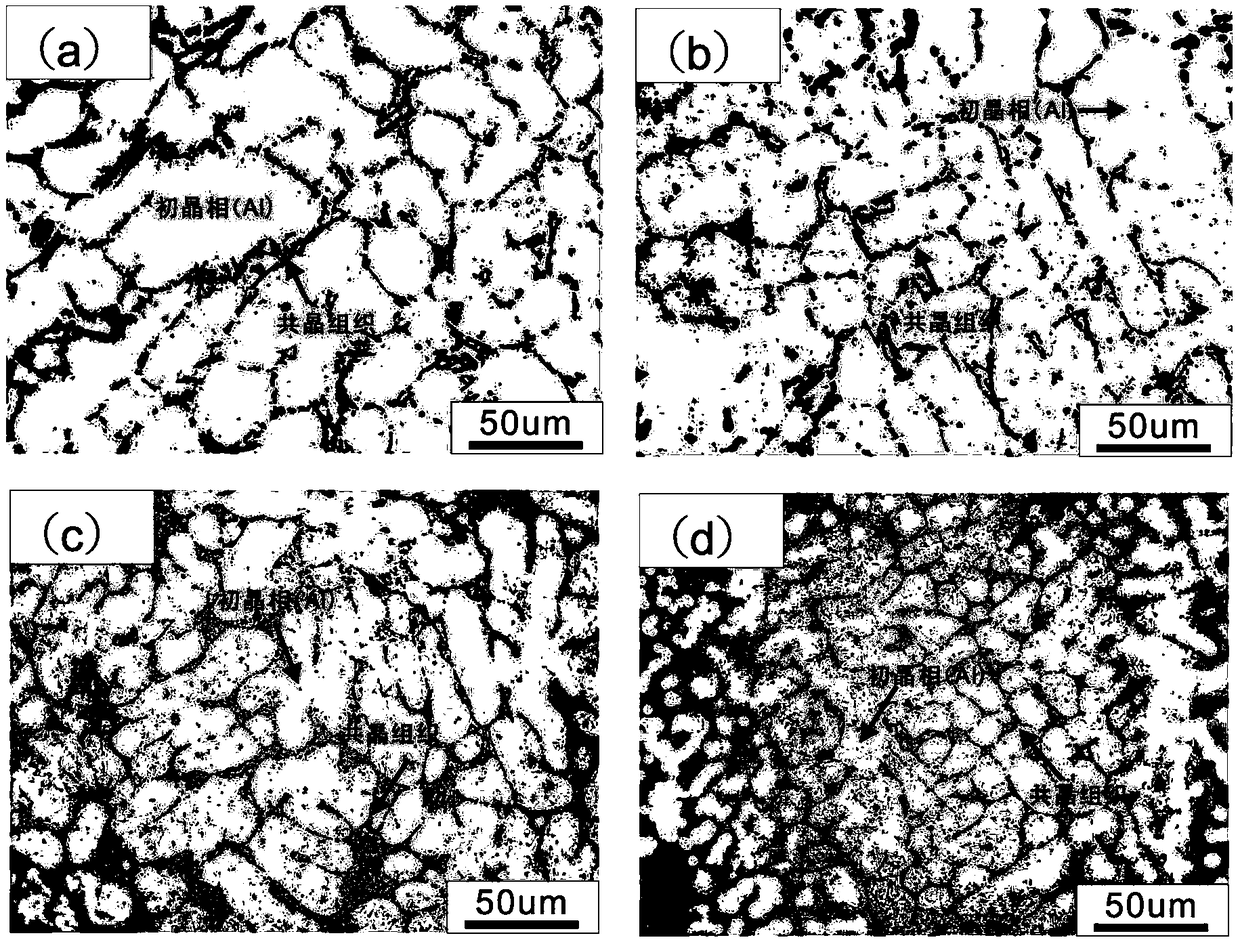

Embodiment 1

[0052] A graphene rare earth scandium synergistically reinforced Al-Si-Mg cast aluminum alloy, wherein the weight percentage of each raw material is: Sc 0.54wt.%, graphene 0.003wt.%, Si 6.90wt.%, Mg 0.40wt.%, Li 0.02wt.%, Be0.02wt.%, B 0.02wt.%, Na 0.02wt.%, P 0.02wt.%, Ti 0.03wt.%, V 0.03wt.%, Cr0.02wt.%, Mn 0.03 wt.%, Fe 0.02wt.%, Ni 0.03wt.%, Cu 0.02wt.%, Zn 0.02wt.%, Zr0.03wt.%, Sn 0.02wt.%, Pb 0.03wt.%, other unspecified Other impurity elements: ≤0.01wt.% for each type, ≤0.10wt.% in total, and the balance is Al.

[0053] The specific preparation method is as follows:

[0054] (1) Take each component raw material according to the alloy proportion, and the total mass is 75 grams;

[0055] (2) Put the weighed raw material into the smelting furnace, vacuum and wash it, fill it with high-purity argon to 500Pa as a protective gas, and heat up to 605°C to melt the raw material;

[0056] (3) After the alloy is melted, heat up to make the alloy homogenize at 720°C for 5 minutes...

Embodiment 2

[0061] A graphene rare earth scandium synergistically reinforced Al-Si-Mg cast aluminum alloy, wherein the weight percentage of each raw material is: Sc 0.54wt.%, graphene 0.003wt.%, Si 6.90wt.%, Mg 0.40wt.%, Li 0.02wt.%, Be0.02wt.%, B 0.02wt.%, Na 0.02wt.%, P 0.02wt.%, Ti 0.03wt.%, V 0.03wt.%, Cr0.02wt.%, Mn 0.03 wt.%, Fe 0.02wt.%, Ni 0.03wt.%, Cu 0.02wt.%, Zn 0.02wt.%, Zr0.03wt.%, Sn 0.02wt.%, Pb 0.03wt.%, other unspecified Other impurity elements: ≤0.01wt.% for each type, ≤0.10wt.% in total, and the balance is Al.

[0062] The specific preparation method is as follows:

[0063] (1) Take each component raw material according to the alloy proportion, and the total mass is 75 grams;

[0064] (2) Put the weighed raw material into the smelting furnace, vacuum and wash it, fill it with high-purity argon to 500Pa as a protective gas, and heat up to 605°C to melt the raw material;

[0065] (3) After the alloy is melted, heat up to make the alloy homogenize at 720°C for 5 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com