Polypropylene composite material and preparation method thereof

A composite material, polypropylene technology, applied in the field of plastics, can solve the problems of easy water absorption and contamination, easy breeding of bacteria and mildew, restrictions on the selection and application of polypropylene materials, etc., to broaden the application field, excellent surface scratch resistance and mechanical properties , Improve the effect of antibacterial and mildew resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

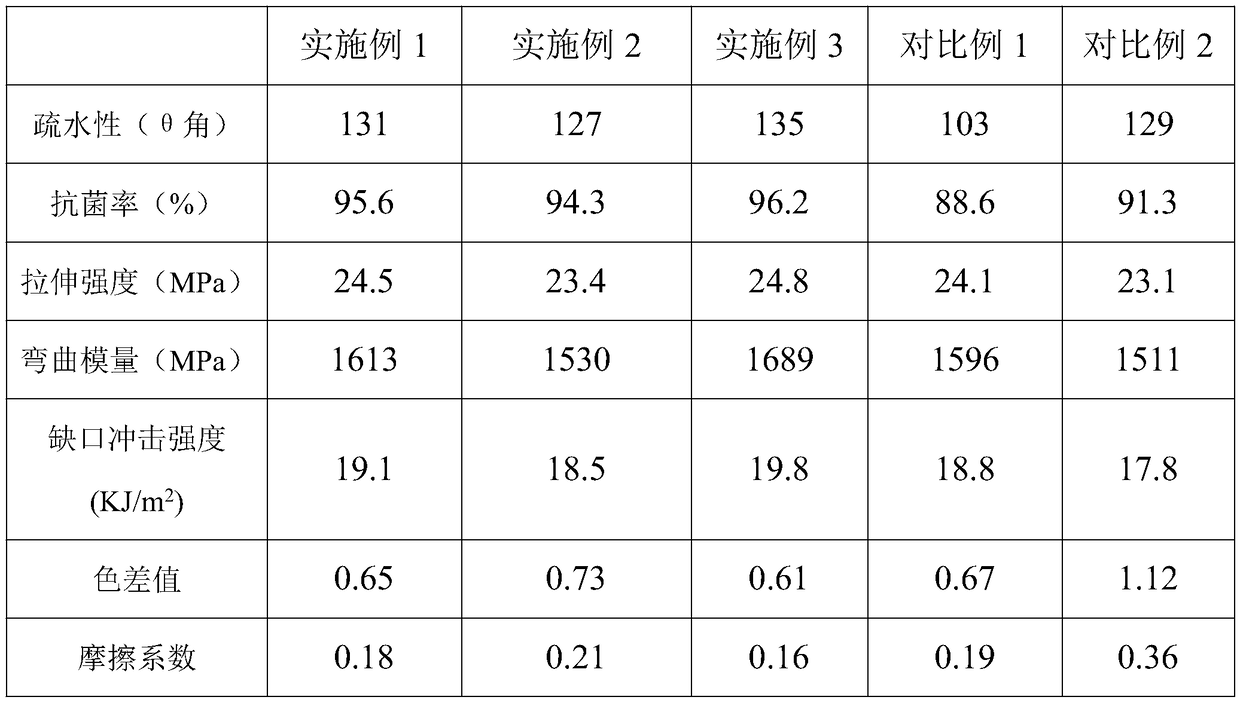

Examples

Embodiment 1

[0020] A polypropylene composite material, calculated in parts by weight, comprises the following components:

[0021] 66 parts of polypropylene copolymer, 19 parts of talcum powder, 5 parts of nano-zinc oxide modified by silane coupling agent, 7 parts of silicone rubber, 2 parts of isopropyl tris(dioctyl phosphate acyloxy) titanate, ethylene-octyl 8 parts of vinyl copolymer, 0.5 parts of tris(2,4-di-tert-butylphenyl) phosphite and 1 part of polyethylene wax.

[0022] Preparation:

[0023] 1) First mix talcum powder, silicone rubber, isopropyl tris(dioctyl phosphate acyloxy) titanate, 35% of the total mass of polypropylene copolymer and 15% of the total mass of ethylene-octene copolymer Uniform, prepare masterbatch with internal mixer;

[0024] 2) the masterbatch obtained in step 1) and silane coupling agent modified nano-zinc oxide, tris(2,4-di-tert-butylphenyl) phosphite, polyethylene wax, remaining ethylene-octene copolymer and The remaining copolymerized polypropylene i...

Embodiment 2

[0026] A polypropylene composite material, calculated in parts by weight, comprises the following components:

[0027] 60 parts of homopolypropylene, 15 parts of talc powder, 3 parts of nano zinc oxide modified by silane coupling agent, 10 parts of silicone rubber, 1 part of isopropyl titanate triisostearate, 5 parts of ethylene-α-olefin polymer 0.2 parts of tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and 0.5 parts of polyethylene wax.

[0028] Preparation:

[0029] 1) First mix talcum powder, silicone rubber, isopropyl titanate triisostearate, homopolypropylene accounting for 30% of the total mass and ethylene-α-olefin polymer accounting for 20% of the total mass, and use a dense The masterbatch is prepared from the kneading machine;

[0030] 2) Mix the masterbatch obtained in step 1) with silane coupling agent modified nano-zinc oxide, tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, polyethylene wax 1....

Embodiment 3

[0032] A polypropylene composite material, calculated in parts by weight, comprises the following components:

[0033] 35 parts of copolymerized polypropylene, 35 parts of homopolypropylene, 25 parts of talcum powder, 6 parts of nano zinc oxide modified by silane coupling agent, 5 parts of silicone rubber, isopropyl tri(dioctyl phosphate acyloxy) titanic acid 3 parts of ester, 10 parts of ethylene-octene copolymer, 0.8 part of dioctadecyl thiodipropionate and 1.5 parts of polyethylene wax.

[0034] Preparation:

[0035] 1) First mix talcum powder, silicone rubber, isopropyl tri(dioctyl phosphate acyloxy) titanate, polypropylene resin accounting for 40% of the total mass and ethylene-octene copolymer accounting for 10% of the total mass Uniform, prepare masterbatch with internal mixer;

[0036] 2) The masterbatch obtained in step 1) is mixed with silane coupling agent modified nano-zinc oxide, dioctadecyl thiodipropionate, polyethylene wax, remaining ethylene-octene copolymer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com