A two-fluid granulation method of soft magnetic composite powder for molding inductors

A technology of soft magnetic composite and soft magnetic powder, which is applied in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc. It can solve problems such as no fluidity, adhesion to device walls, flying dust, etc., and achieve high inductance and high Effects of stability, improved moldability, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

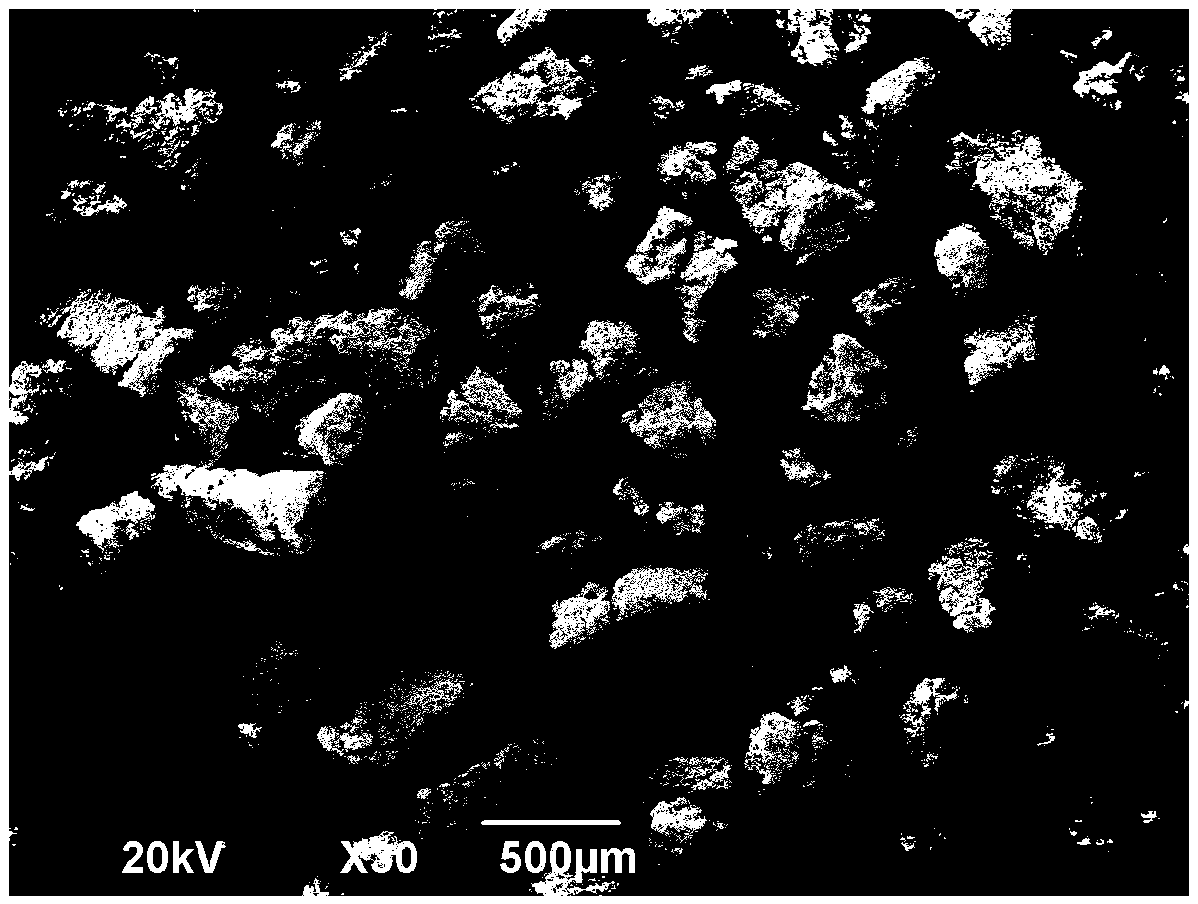

Image

Examples

Embodiment 1

[0025] The two-fluid granulation method of the soft magnetic composite powder for molded inductors of the present embodiment comprises the following steps:

[0026] (1) Add iron-silicon-chromium alloy powder (FeCrSi-C) into acetone in which phosphoric acid (analytically pure) has been dissolved, and place it in a double planetary mixer and stir for 40 minutes. At the same time, the system is heated and ventilated, and the heating temperature is 45°C , then take out the powder, the quality of phosphoric acid and acetone are respectively 0.5%, 12% of the FeSiCr alloy powder quality in this step;

[0027] (2) Take soft magnetic powder molding glue, epoxy resin and phenolic resin respectively, and dissolve in acetone to form adhesive;

[0028] (3) Mix the pretreated iron-silicon-chromium alloy powder with the adhesive, and place it in a double planetary mixer to fully stir to form a two-fluid granulation puree. The mixer speed is set to 40 rpm, and the mixing time is 15-30min. Th...

Embodiment 2

[0041]The two-fluid granulation method of the soft magnetic composite powder for molded inductors of the present embodiment comprises the following steps:

[0042] (1) Add carbonyl iron powder into acetone dissolved with phosphoric acid (analytically pure), and place it in a double planetary mixer to stir for 40 minutes. At the same time, the system is heated and ventilated. The heating temperature is 45°C, and then the powder is taken out. This step The mass of phosphoric acid and acetone are respectively 0.5% and 12% of the carbonyl iron powder mass;

[0043] (2) Take soft magnetic powder molding glue, epoxy resin and phenolic resin respectively, and dissolve in acetone to form adhesive;

[0044] (3) Mix the pretreated carbonyl iron powder with the adhesive, and place it in a double planetary mixer to fully stir to form a two-fluid granulation puree. The mixer speed is set to 40 rpm, and the mixing time is 15-30min. The precipitated emulsion is the two-fluid granulation pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com